- info@cnygm.com

- +(0)86-576-88122360

Your Reliable Reflective Sheeting Supplier

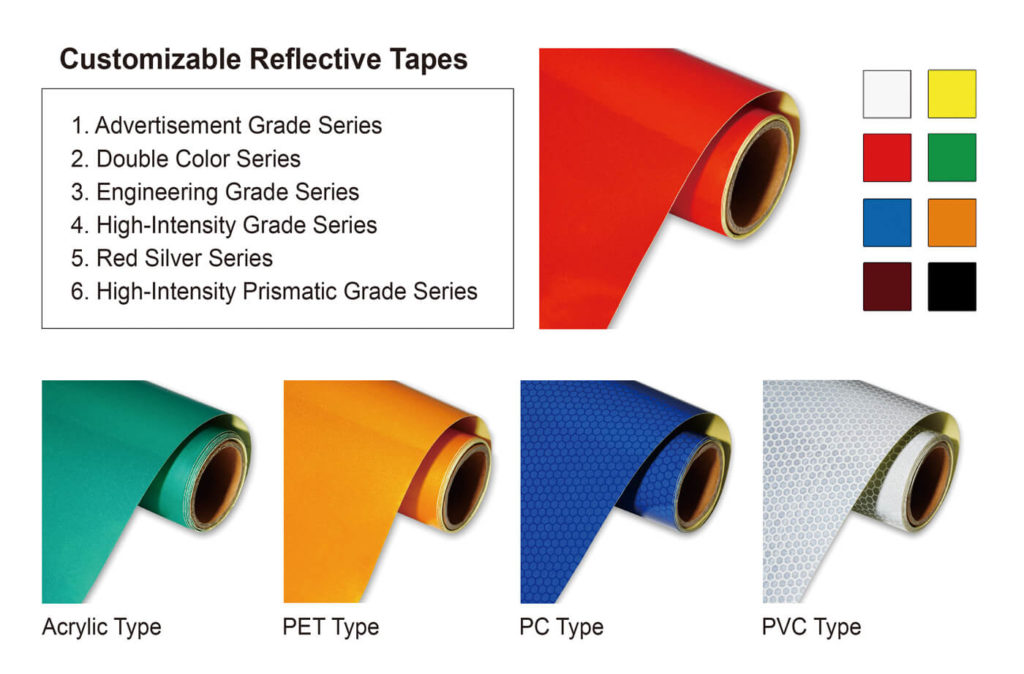

Multiple Types | Customized Stripes & Logos

- While reflective material must be sewn to material, reflective sheeting can be applied simply with a self-adhesive. If you are looking for a solution to make your branding more noticeable, then you can try YGM’s Reflective Sheeting. This self-adhesive sheet can be attached to any clean surface, such as road signs, parking areas, shopping centers, and even vehicles. With YGM reflective sheeting, you can enjoy as much personalization as possible. Apart from sending your design for the reflective sheet, you can also specify the dimensions according to your requirement.

- Whether you want to mark hazardous areas or create a unique advertisement for your company, YGM reflective sheeting has multiple applications and uses. YGM’s reflective sheeting comes with varied reflectivity, depending upon the colour choice. Even with rough usage, this durable reflecting sheeting will not tear or fade over time. The high-intensity prismatic grade reflective tape can last up to 10 years!

Why choose YGM Reflective Sheeting?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

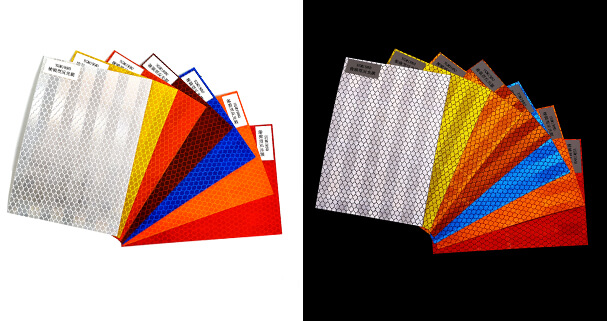

Reflective Sheeting Category

Advertisement Grade Reflective Sheeting

● Types: PET / Acrylic type

● Service life: 3 years

● Feasible operating temperature:

○ PET type: 5-30℃

○ Acrylic type: 18-28℃

● Color: White, yellow, red, green, blue, orange, brown, black

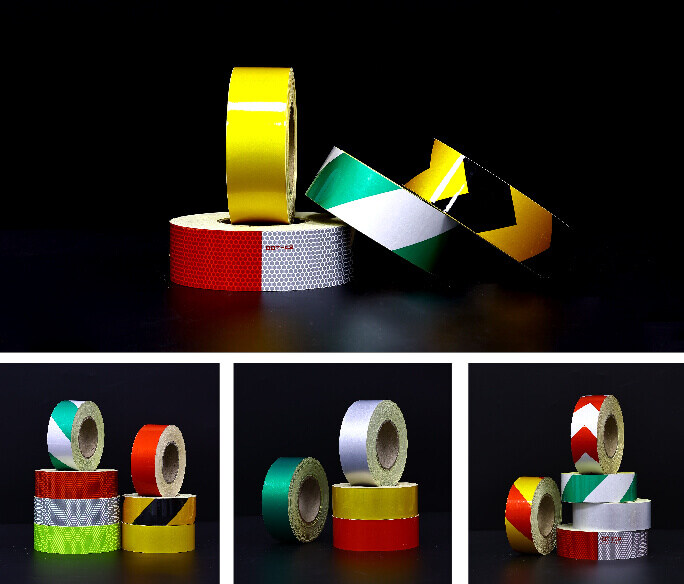

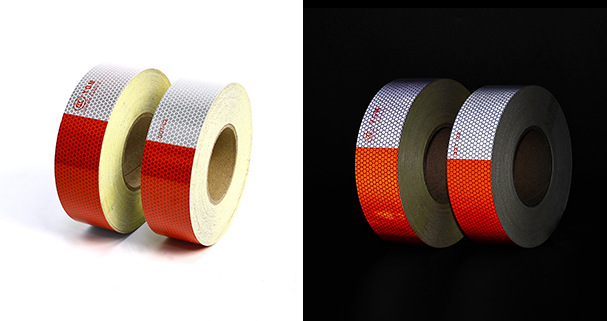

Double Color Reflective Sheeting

● Types: PET / Acrylic type

● Service life: 3 years

● Feasible operating temperature:

○ PET type: 5-30℃

○ Acrylic type: 18-28℃

● Color: Red&white, yellow&black, yellow&red, orange&white, blue&white

Engineering Grade Reflective Sheeting

● Types: PET / Acrylic type

● Service life: 5 years

● Feasible operating temperature:

○ PET type: 5-30℃

○ Acrylic type: 18-28℃

● Color: White, yellow, red, green, blue, orange, brown, black

High Intensity Grade Reflective Sheeting

● Types: PET / PC / PVC type

● Service life:

○ PET type: 5 years

○ PC type: 7 years

○ PVC type: 3 years

● Feasible operating temperature: 5-30℃

● Color: White, yellow, red, green, blue, brown

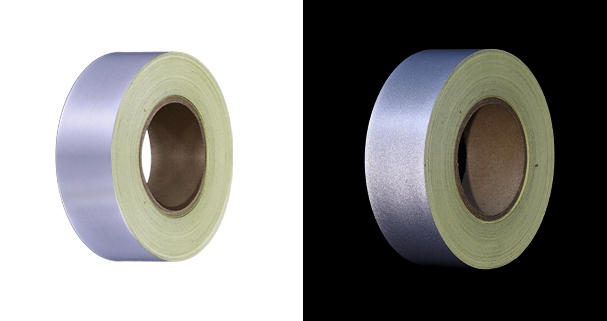

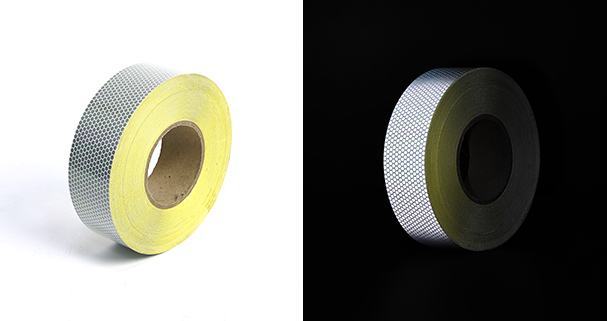

Red Silver Reflective Sheeting

● Service life: 7 years

● Feasible operating temperature: 5-30℃

● Color: Red&white

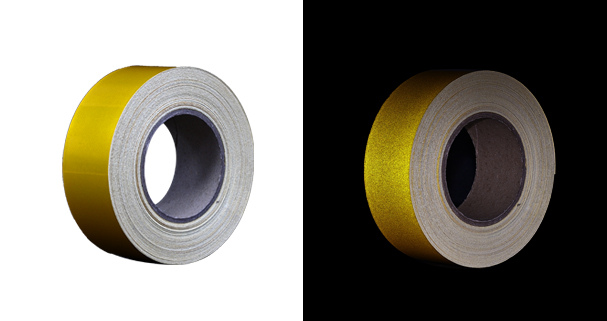

High Intensity Prismatic Grade Reflective Sheeting

● Service life: 10 years

● Feasible operating temperature: 18-28℃

● Color: White, orange

Best Reflective Sheeting: Uses, Application, Materials, and More

Table of Contents

Have you ever wished there were glow-in-the-dark signs everywhere? Signage like hazard warnings or road signs needs to be visible in low light conditions. Even for promotional purposes, many companies wish that their advertisements were more visible to their potential market.

To solve all these problems, you can opt for reflective sheeting. While traditional reflective material had to be sewn onto materials, reflective sheeting has an easy application through a self-adhesive.

Reflective sheeting uses light from the environment to illuminate itself. This feature ensures that a sign made with reflective sheeting is visible during the night or in poorly lit areas.

This informative article covers everything you need to know about reflective sheeting. Keep reading to find out more about what reflective sheeting is and how it can be used for various applications.

What is Reflective Sheeting?

Reflective vinyl sheets are like paper that lights up using ambient light.

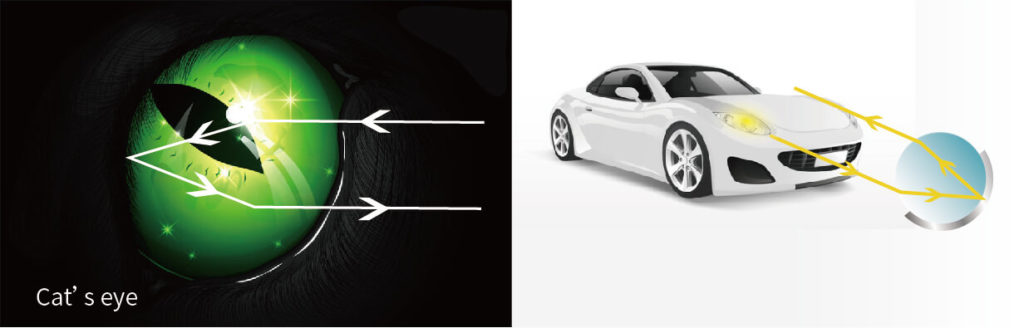

The reflective plastic sheet is made using retroreflective glass beads or micro prisms. The glass beads surface reflects light back to the source, which makes the sheet visible in any light condition. Apart from being visible from a great distance, reflective sheeting is also suitable for all types of weather conditions.

YGM’s reflective adhesive vinyl can be customized according to your requirements. From design or lettering to the size, you can personalize the reflective sheeting to attach to walls, signboards, or even vehicles.

How are Reflective Signs Made?

If you can clearly see traffic signs on the road during the night, then they are probably made using reflective sheet material.

All reflective signs are made using reflector film on an anodized Aluminum substrate material. Made using premium quality materials, YGM promises extensive quality control measures that ensure every piece of reflective sheeting is up to the standard.

Since YGM already manufactures these reflective vinyl sheets, they can customize each sheet as per the customer’s requirement. Once the customized reflection vinyl is created, the reflective sheet can be attached to any flat surface using self-adhesive.

Types of Reflective Sheeting

The reflective sheet material is available in a range of types, each with its unique set of features. These types of silver heat reflective sheets differ in terms of reflectivity, service life, durability, and applications.

- Advertisement Grade Reflective Sheeting

Advertisement grade reflective sheeting is the most basic type of vinyl adhesive sheet available in the market. You can choose between the PET type that is great for operational usage or the acrylic type that is suitable for screen printing designs.

This type of reflective vinyl sheeting can last up to 3 years, which makes it great for advertisements or temporary road signs. A range of standard colors such as white, green, red, blue, black, etc. are available, but YGM also offers further customized options in color.

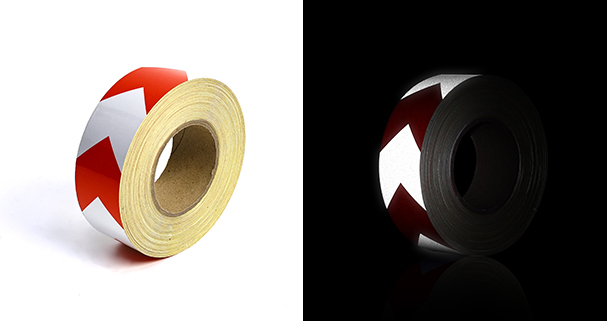

- Double Color Reflective Sheeting

Color combinations such as red and white, yellow and black, and orange and white can be found in this type of reflective sheeting. Similar to advertisement grade reflective sheeting, double color vinyl adhesive sheets are also available in PET and acrylic types.

With a service life of 3 years, these double color reflective sheets are commonly used for advertisement purposes since the dual-color attracts attention. Since bright colors like yellow and orange are used, this reflective sheeting can also be used to create warning or hazard signs for roads, factories, or construction sites.

- Engineering Grade Reflective Sheeting

If you are looking for more durable reflective sheeting for traffic signs, consider using the engineering-grade sheets by YGM. These reflective adhesive sheets can be customized according to your color and size preference.

For a lasting reflective sheet, opt for the untearable PET type. If you plan to apply the reflective vinyl at a height, then you can also use the acrylic type that is great for screen printing and digital cutting. Visibility levels for both types are up to 500ft during the night.

Since the engineering grade reflective sheeting can last for up to 5 years, it is typically used for industrial safety signs, road signs, and large-scale signboards. Some companies also opt for engineering-grade reflective sheeting to ensure that the ad outside their shop can last for multiple years without needing an upgrade.

- High-Intensity Grade Reflective Sheeting

If you need a reflective adhesive vinyl that can be seen from a distance of up to 1,000 ft, then YGM’s high-intensity grade reflective sheeting should be your top choice. All three types (PET, PC, PVC) are untearable and offer a long service life of between 5-7 years. While the PET type has the greatest reflectivity, the PVC type is great for screen or digital printing.

You may find high-intensity grade reflective sheeting at the back of vehicles such as industrial trucks or boats. For busy roads or highways, high-intensity grade reflective sheeting is used to ensure that drivers can see road signs from far away.

- Red Silver Reflective Sheeting

For a reflective vinyl sheet that immediately catches everyone’s attention, you can opt for YGM’s red silver reflective sheeting. This unique color combination has a high reflectivity ratio and can last up to 7 years of rough usage.

Even under unfavorable weather conditions, you can count on the red silver reflective sheeting to stay intact. Apart from using this adhesive vinyl on cars and trucks, you can also use it to customize industrial helmets, backpacks, and cycles.

If you frequently travel during the night, then having a red silver reflective sheeting on your helmet and motorcycle can help you stay safe from potential road accidents.

- High-Intensity Prismatic Grade Reflective Sheeting

While other types of vinyl adhesive sheets use retroreflective glass beads to illuminate, this type uses the most modern technology. Prismatic grade reflective sheeting means that light bounces off the surface of this sheet at three points instead of two, offering a brighter light and greater reflectivity ratio.

Not only is the prismatic grade reflective sheeting more efficient, but it is also more durable in terms of service life. Despite rough usage or harsh outdoor weather conditions, the high-intensity prismatic grade reflective sheeting can last up to 10 years.

For semi-permanent vehicle markings or road crossings, using high-intensity prismatic grade reflective sheeting sounds like the best choice.

How is Reflective Sheeting Customized?

YGM can create any design or lettering using reflective sticker paper. Depending upon the volume of your order, the design can be cut on the sheet using three different methods.

The first method is silk screening or using mesh to transfer ink onto the reflective plastic. Although silk screening is a relatively old method of printing, it still provides high-quality results on the reflective vinyl sheet.

If you use a silkscreen for reflective sheet printing, then it is possible to replicate the same design on multiple sheets. This printing method is perfect for applications such as printing road signs, warning signs, or other commonly used signs that need to be standardized.

The second method is by cutting the color reflective vinyl using high-grade equipment. Once a design is digitally sent to the machine, the cutter works automatically to cut the perfect design into the reflective sheeting. This type of printing is suitable for applications that require cutting complicated designs such as calligraphy lettering and logos.

Lastly, reflective vinyl sheets can also be customized using digital printing. Using a thermal resin printer, any design can be printed onto the reflective plastic sheet. This method of customizing reflective sheeting is typically used for PVC applications.

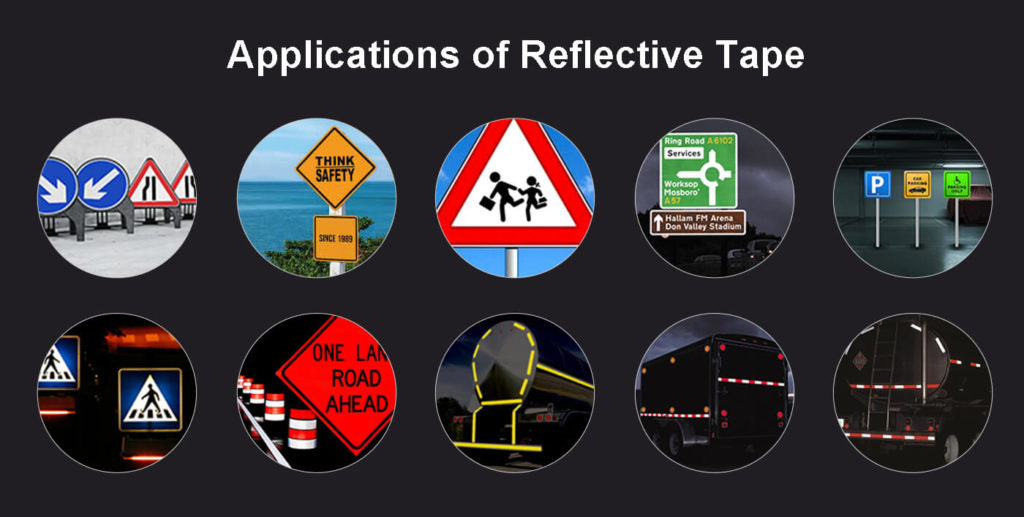

Uses of Reflective Sheeting

If you haven’t already noticed, there are multiple ways of using vinyl reflective sheeting. From personal use to commercial use, reflective sheeting can be completely customized to suit your specific requirements.

Here are a few ways that you can use YGM reflective sheeting:

- Vehicles and Trailers

Commercial vehicles tend to travel on highways during the night where they often become involved in accidents. To ensure that other drivers on the road can spot a commercial vehicle or trailer from afar, you can attach reflective vinyl sheeting at the back.

If your company has multiple transport vehicles, then consider using reflective vinyl sheeting to attach the brand logo and slogan at the back. This technique can also serve as a great method of advertisement as it helps increase brand awareness and creates a positive brand image.

- Bike Helmets

If you ride a cycle or motorbike during the night, it is important to prioritize your safety and wear a helmet. To avoid drivers running into you on the main road, consider applying YGM reflective vinyl sheets on your helmet. You can even customize the design to include artwork of your choice on the bike helmet.

- Bollards and Pillars

Wrapping reflective adhesive tape around large pillars can prevent a wide range of accidents. Especially in low-light areas such as underground parking lots, having reflective sheeting around the bollards can ensure that every driver sees the pillar.

- Low Hanging Objects

This use for reflective sheeting applies to both personal settings and commercial buildings. If you keep the garage door halfway down, then applying a small reflective sheet on the edge can prevent people from accidentally running into the door.

At work, it can be beneficial to apply reflective sticker paper where a forklift is operating.

- Warehouse Floors

Factories and warehouses tend to have a range of heavy machinery and high voltage equipment. To prevent accidents, you can apply reflective plastic sheets to mark every hazardous area on the warehouse floor.

How is Reflective Sheeting Applied?

Whether you are applying the reflective vinyl sheet to a wall or at the back of a vehicle, it is essential to clean the surface first. To ensure that the reflection vinyl sticks properly, the surface should be free of dust, dirt, and debris.

Clean the surface with 70% rubbing alcohol or isopropyl alcohol (IPA) before starting the application procedure. Check the dimensions of your vinyl sheet and make sure that you clean enough area to stick the entire reflective adhesive vinyl.

Once the surface is prepared, you can start by peeling off the paper at the back gradually. Then, position the reflective sticker paper in the correct position and press firmly onto the surface. The self-adhesive should take a few seconds to attach permanently to a clean surface.

Depending upon the type of reflective sheeting used, you may need to be extra careful during application to avoid rips and tears. Remember that the acrylic type of reflective sheeting is prone to tearing, whereas the PET, PC, and PVC types are untearable.

How Long Does Reflective Sheeting Last?

YGM reflective sheeting can last between 3 to 10 years, depending upon the type of sheet that you choose.

Not everyone wants a permanent reflective sheet, which is why advertisement grade and double color reflective tape only lasts for three years. For semi-permanent uses such as road signs and traffic markers, engineering grade reflective tape offers up to 5 years of service life.

The longest service life is offered by red silver reflective tape and high-intensity prismatic grade reflective tape of 7 and 10 years respectively. While reflective sheeting can be used in a variety of applications, it is important to choose the type that is most suitable for your requirements.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang