- info@cnygm.com

- +(0)86-576-88122360

Rainbow Reflective

Heat Transfer Vinyl

Your Trustworthy Rainbow Reflective Heat Transfer Vinyl

Manufacturer Supplier

Your Reliable Rainbow Reflective HTV Supplier

Multiple Types | Customized Stripes & Logos

Introduction to Rainbow Reflective HTV

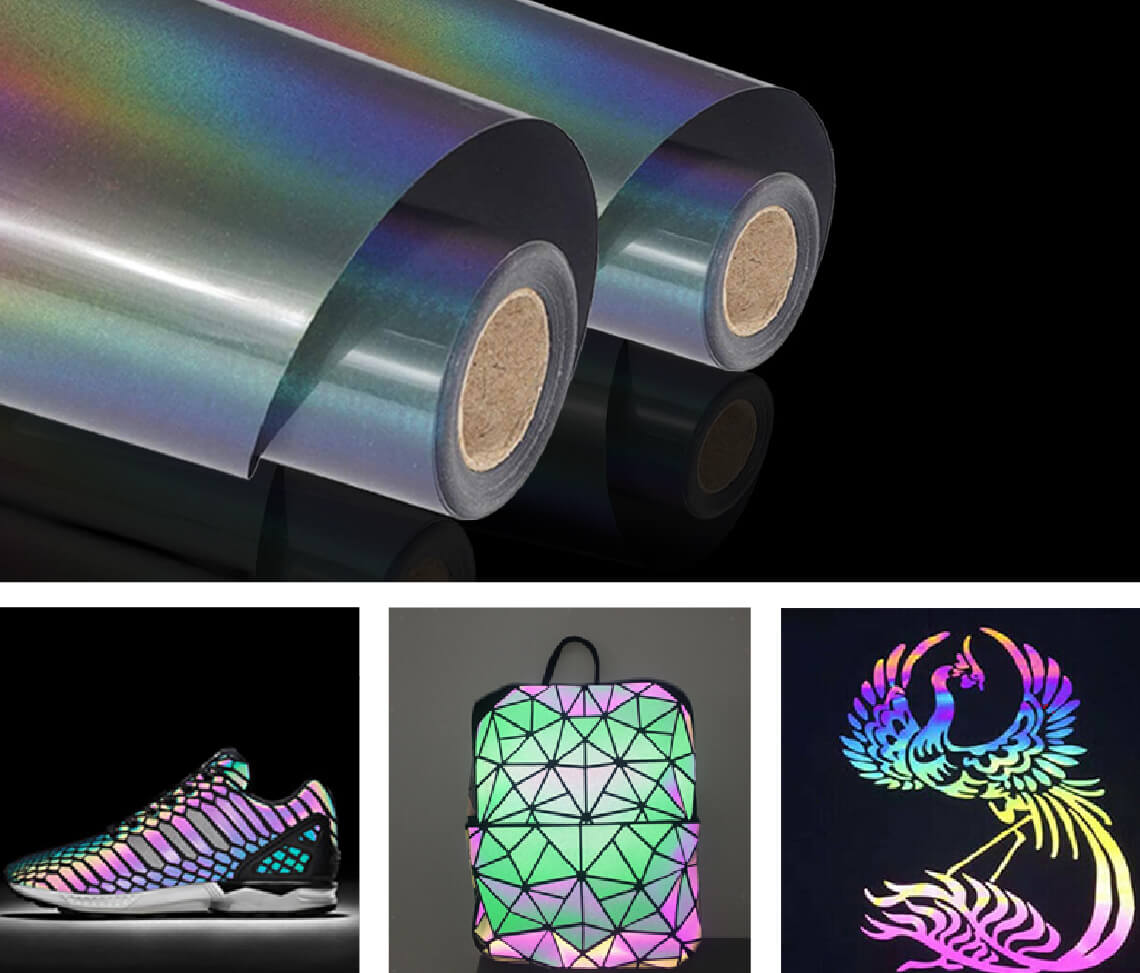

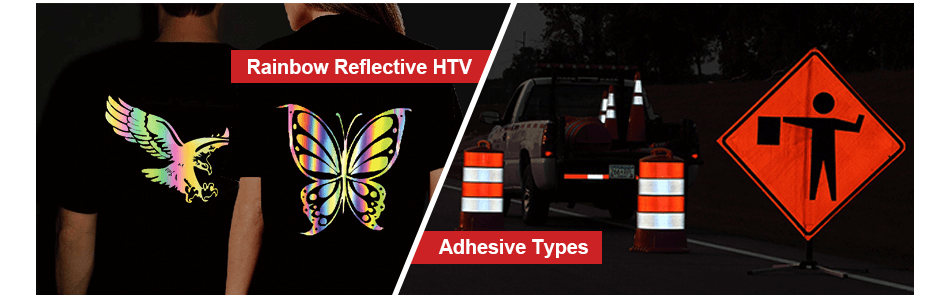

Rainbow reflective heat transfer vinyl is one kinds of reflective heat transfer vinyl, a polymer made to cut the hassle of stitching or taping reflective fabric to products like clothes, shoes, backpacks, bags and so on. It’s an innovative material that can be cut using a plotter, knife, or laser to create designs, fashions, patterns and logos on all kinds of materials.

Made from backing material of TPU and PES, this is a versatile material that’s excellent for a variety of fashion and safety uses. Whether you’re looking for holographic reflective vinyl or a new fashion statement to revolutionize the industry, rainbow reflective vinyl is all you need. It’s durable with excellent resistance to washing and natural wear.

Rainbow Reflective Heat Transfer Vinyl Features

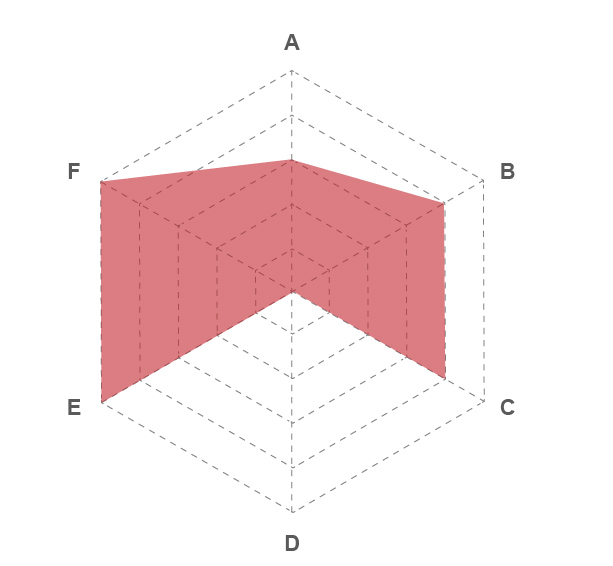

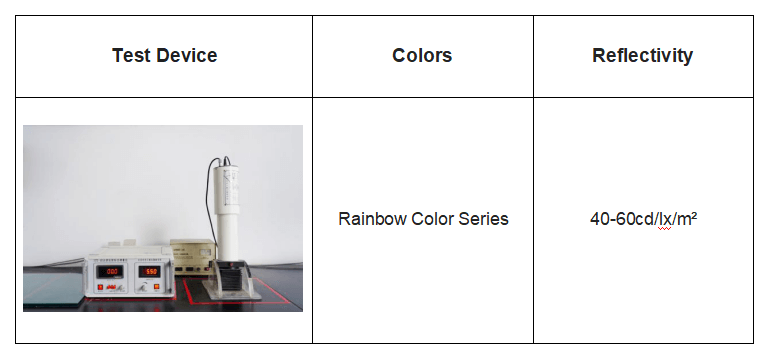

A: Reflectivity

Depending on the reflectivity of a material, you can use it for visibility at day, night or even fashion purposes. Rainbow reflective heat transfer vinyl is a unique material with expert reflectivity of 40 to 60 cd/lx/m².

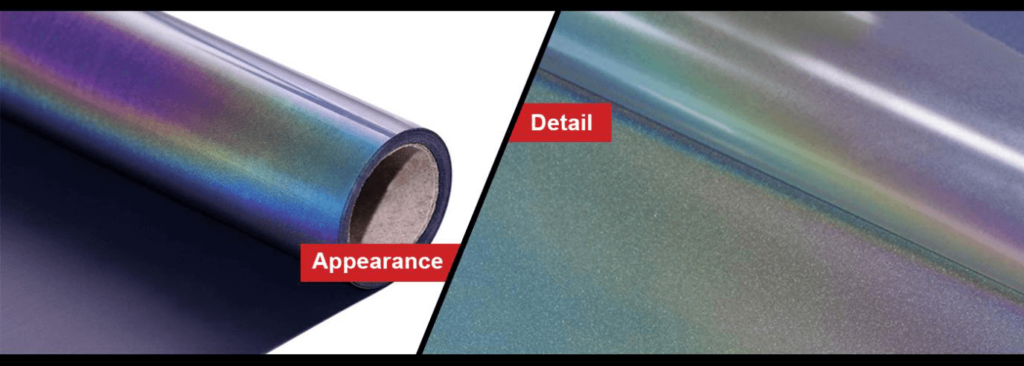

B: Color

In the field of reflectivity, every color has its own traits and virtues that specify its reflectivity. As Rainbow Reflective HTV is an iridescent material, it’s a combination of all the colors such as violet, indigo, blue, green, yellow, orange, and red in addition to white, silver, and gold. You can select from different rainbow patterns on the material based on the different placement of glass beads.

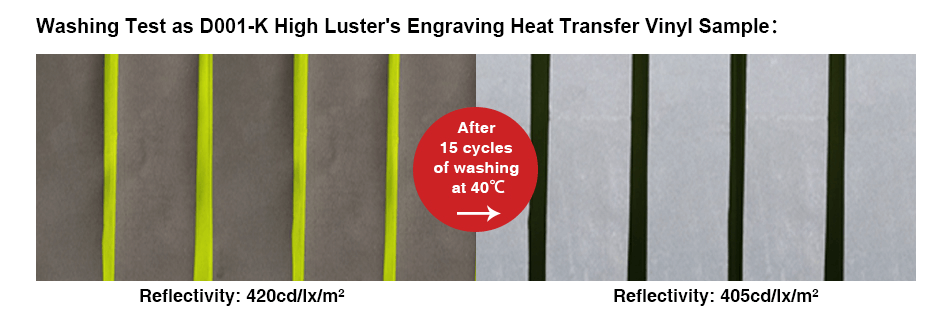

C: Washability

Washing these HTV fabrics is not much of a difficult task. There are several options you can carry out to clean it and make it look tidy. So, we have the three main options.

D: Flame Retardancy

Unlike most reflective heat transfer vinyl, rainbow reflective heat transfer vinyl isn’t resistant to fires. It’s easy to catch fire and you should avoid exposing it to flammable items and flames. Rainbow reflective HTV shouldn’t be used for fireproof webbing and clothing.

E: Customizability

It’s easy to customize the rainbow reflective HTV according to your demands. You can use a knife, plotter or laser machine to cut the material into different patterns, logos, and other specific shapes according to your requirements.

F: Applicability

What are all the places you can use rainbow reflective heat transfer vinyl? Starting from the world of fashion like tees, tops, blouses, shirts, jackets and coats to safety wear like overalls, workwear, shoes, backpacks and branding elements (for placing logos), the many options to use rainbow reflective heat transfer vinyl are many.

Why Choose YGM Rainbow Reflective HTV?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Rainbow Reflective HTV Category

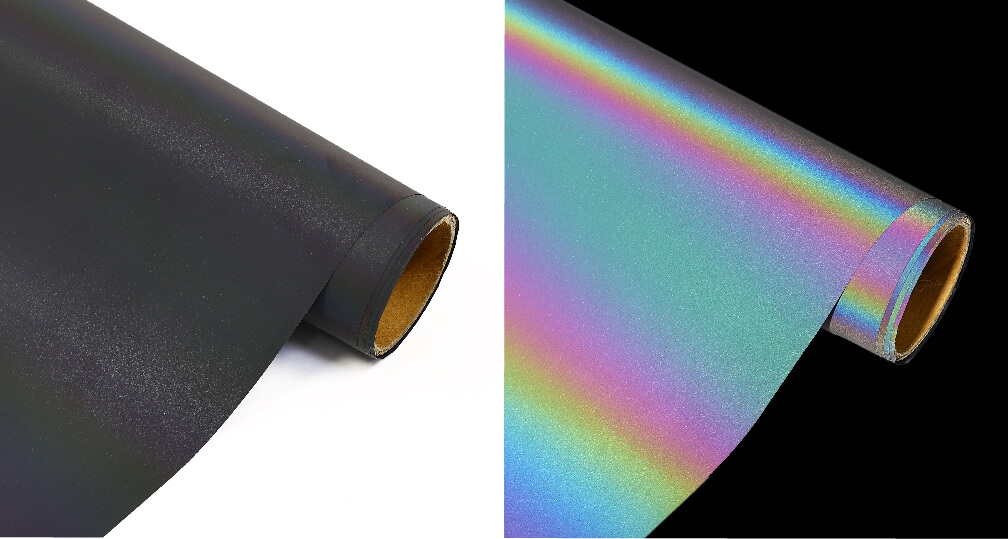

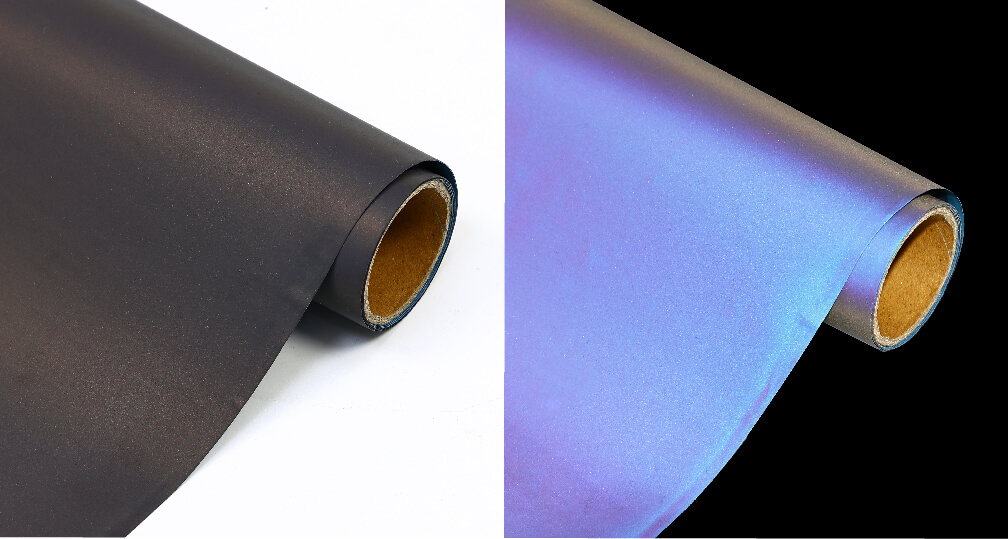

Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: Black

Nighttime: Segmented rainbow

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

Aurora Color Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: Black

Nighttime: Aurora color

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

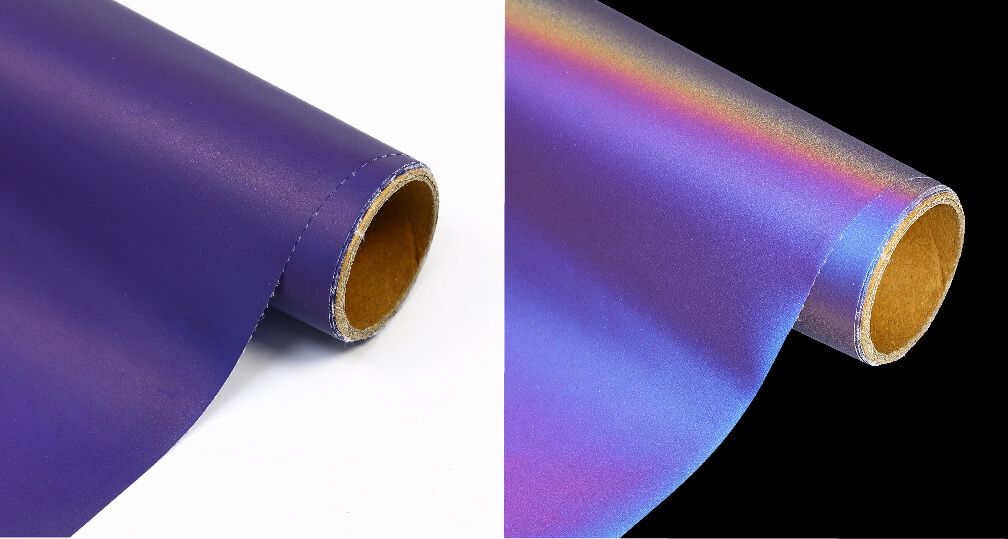

Blue-Purple Light Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: Blue

Nighttime: Blue-Purple Light

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

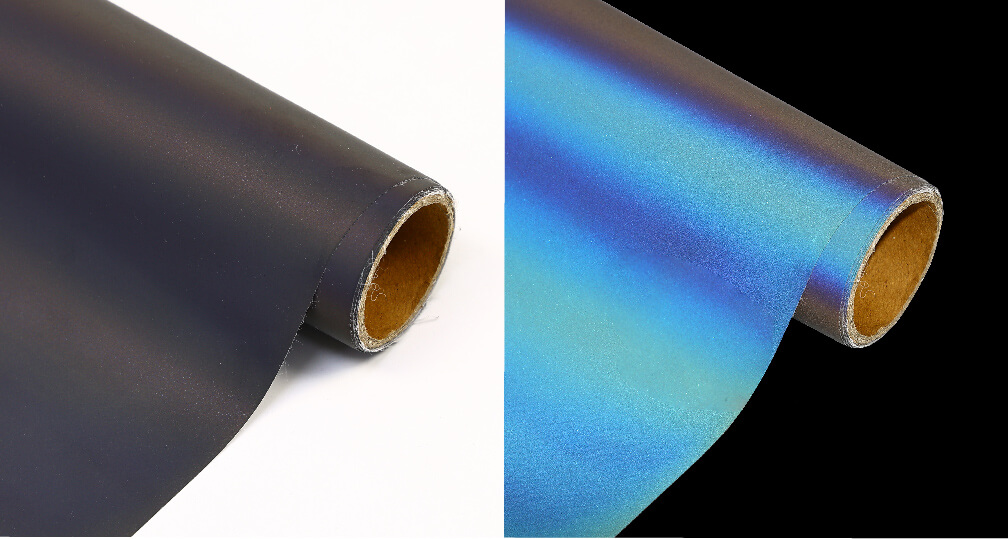

Black Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: Black

Nighttime: Blue-Purple Light

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

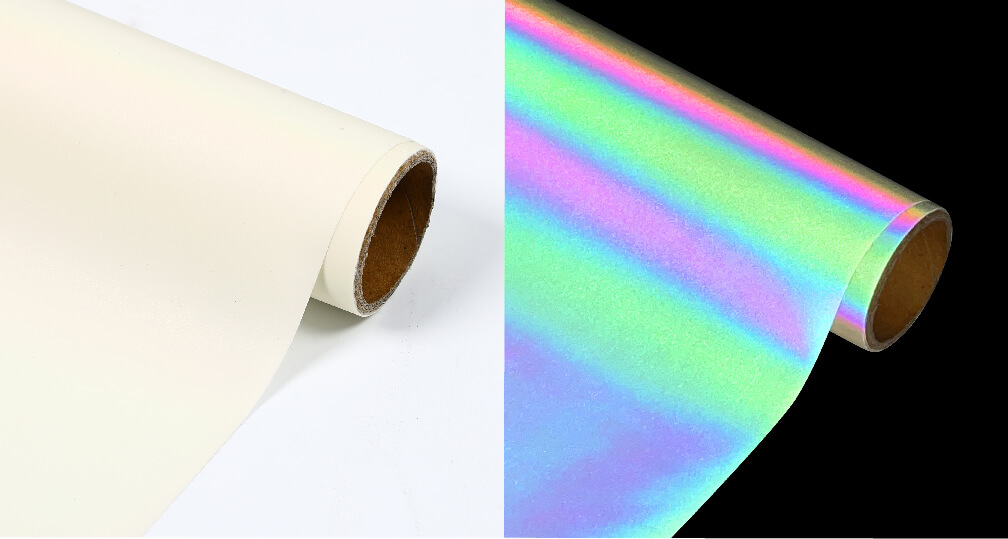

White Fluorescence Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: White

Nighttime: Aurora color

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

White Blue-Purple Light Rainbow Reflective Heat Transfer Vinyl

Reflective Coefficient:>30CPL

Daytime color: White

Nighttime: Blue-Purple Light

Backing Fabric:PES/TPU

Hot Pressing Temperature:130-140℃

Hot Pressing Pressure:4-6kg/cm²

Hot Pressing Time:10-15s

Home Wash Cycles:40℃@25 cycles

Rainbow Reflective HTV:The Complete Buying Guide

Everything you need to know about rainbow reflective heat transfer vinyl is specified below.

Table of Contents

What is rainbow reflective heat transfer vinyl and how does it work?

Rainbow reflective heat transfer vinyl (HTV) is a polymer sheet made of vinyl with an iridescent sheen that’s used on fabric, leather, and similar surfaces for decoration, fashion, patterning, safety, advertising. It’s generally thinner than other reflective fabric but ensures good durability, weather resistance, and elasticity.

Typically displaying the rainbow colors of violet, indigo, blue, green, yellow, orange, and red in addition to white, silver, and gold, this vinyl polymer is created with high-intensity reflective beads. Such a reflective vinyl polymer comes in a sheet or rolled format along with an adhesive backrest for trimming, weeding, and placement during hot pressing.

For you to find that out, check all the things that need to be taken care of, such as time, pressure, temperature, and other overly sensitive consideration while using HTV. Also, check the direction on the vinyl you have used and double-check if all the settings are correct.

● Timing

Ironing it for a nickel of time will not allow it to stick to your things or shirts. Moreover, ironing it for a way longer time will burnout the adhesives.

● Temperature

Different types of vinyl have different temperature needs, and for that, you must test first to make sure that you are using the right kind of temperature for the right kind of vinyl.

● Pressure

This vinyl works well with the right kind of temperature. That kind of temperature can be created by shaking your arms physically and after that pressing it so hard also you must see the weave of the cloth through the vinyl. And if you are not sure about the pressure, you must put on a little more weight.

Now check for the cloths whether you are using the right kind of cloth for pressing the vinyl on or what. For cutting a logo, you must use the right PES type heat transfer vinyl, and for the right kind of fabric, you use one like TPU type. Be sure about what comes first: the vinyl or maybe the jersey, although they are going to fit anyway.

Sometimes thick cotton clothing like collars, buttons or maybe zip can be the problem.

Some other types of HTV may need the carrier to be peeled off once you pressed the iron.While others will need you to cool off the entire thing before you are planning on removing the plastic from the carrier sheet. Take care because removing it inappropriately might affect or destroy your design.

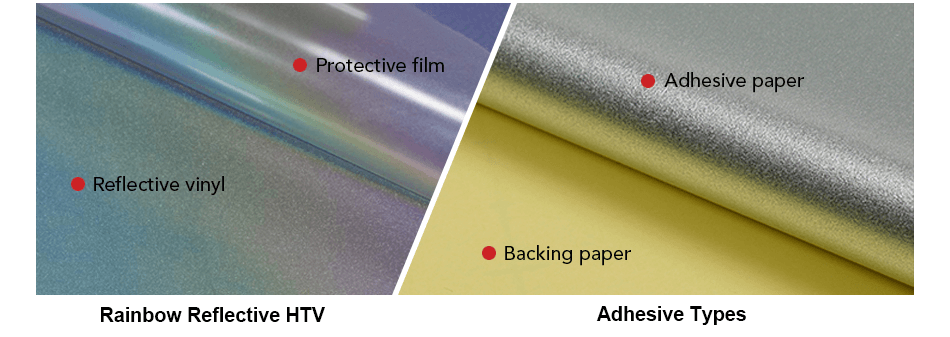

What type of Rainbow Reflective Vinyl does YGM offer?

We at YGM are pioneers in producing multiple types of reflective heat transfer vinyl and our recent addition is reflective rainbow vinyl.

You can get two types of rainbow reflective vinyl with us- one with PES backing (expertly conducts heat) and the other with TPU (a combination of rubber and plastic) backing.

Polyester or PES film is a special material capable of enduring high temperatures. TPU or thermoplastic polyurethane is a thin film added underneath the protector and this backing prevents the release of unfavorable gases during application.

We urge you to choose the backing element based on your requirements or talk to our customer service for more information.

| PES | TPU | |

|---|---|---|

| Composition | Polyester | Thermoplastic Polyurethane |

| Transparency | White Translucent | Transparent, Translucent, Matte |

| Elasticity | General | Very Good |

| Soft and comfortable | General | Very Good |

| Washing | Very Good | General |

| Dry cleaning | Very Good | General |

| Temperature resistance | Good High Temperature Resistance | Good Low Temperature Resistance |

| Hot pressing temperature | 140-150℃ | 130-140℃ |

What is the size of YGM Rainbow Reflective Heat Transfer Vinyl Roll?

When you order rainbow reflective HTV with YGM, you can choose from two options:

- 50cm x 50 m per roll

- 1 m x 50 m per roll

Apart from the above, feel free to consult us for unique dimensions as we also provide customization according to your needs and preferences.

What are the uses of rainbow reflective heat transfer vinyl?

The key uses of rainbow reflective HTV span from decorating t-shirts, hats, caps, and other fashion materials made with textile. Even better use of this material is that you can use it to apply logo or branding details on shoes and bags using cutting techniques with a knife or laser.

Altogether, it ensures higher visibility, safety, and security, besides looking fashionable and rad. Besides being easy-to-apply, rainbow reflective vinyl is ideal for running, cycling, biking, or walking at night.

Why do you need rainbow reflective HTV?

When it comes to needs over preferences, rainbow reflective heat transfer vinyl is a unique material that combines the best of safety and style.

On top of that, this material also comes with a long line of benefits as shown below:

● Invincible

The best thing about rainbow reflective heat transfer vinyl is that it is non-destructive and a seamless product that doesn’t negatively impact the material during application. For instance, it’s effortless to imbue rainbow reflective vinyl material on the waterproof material. When doing so, the water-resistance of the material doesn’t go down. Moreover, this cuts the need for you to treat the same material again with waterproof processes.

● Easy-to-process

Whether you have a cutting plotter, or a fully-fledged laser device, it’s easy to work with our material. In fact, you can cut or engrave designs on the rainbow reflective vinyl you receive from YGM on your own without any professional help.

● Aesthetic

The next most important feature of our rainbow reflective vinyl polymer is that it’s better than silk-screen printing when it comes to flatness. Besides, patterning or adding stripes to this material is a cakewalk because it’s smoother, amenable, flexible, and elegant when you hot press the same on any heat transfer vinyl.

● Trendy

From Nike to Adidas, ASOS, Akira, Vespertine NYC, and many other luxury brands, there are endless world leaders already using rainbow reflective HTV for bringing unique products to their inventory.

● Dynamic

From athletics to gymnastics, and sports, rainbow reflective HTV is versatile to work for sportswear, fashion clothing, athletics and much more. It’s ideal for clothes as well as accessories like shoes and handbags too.

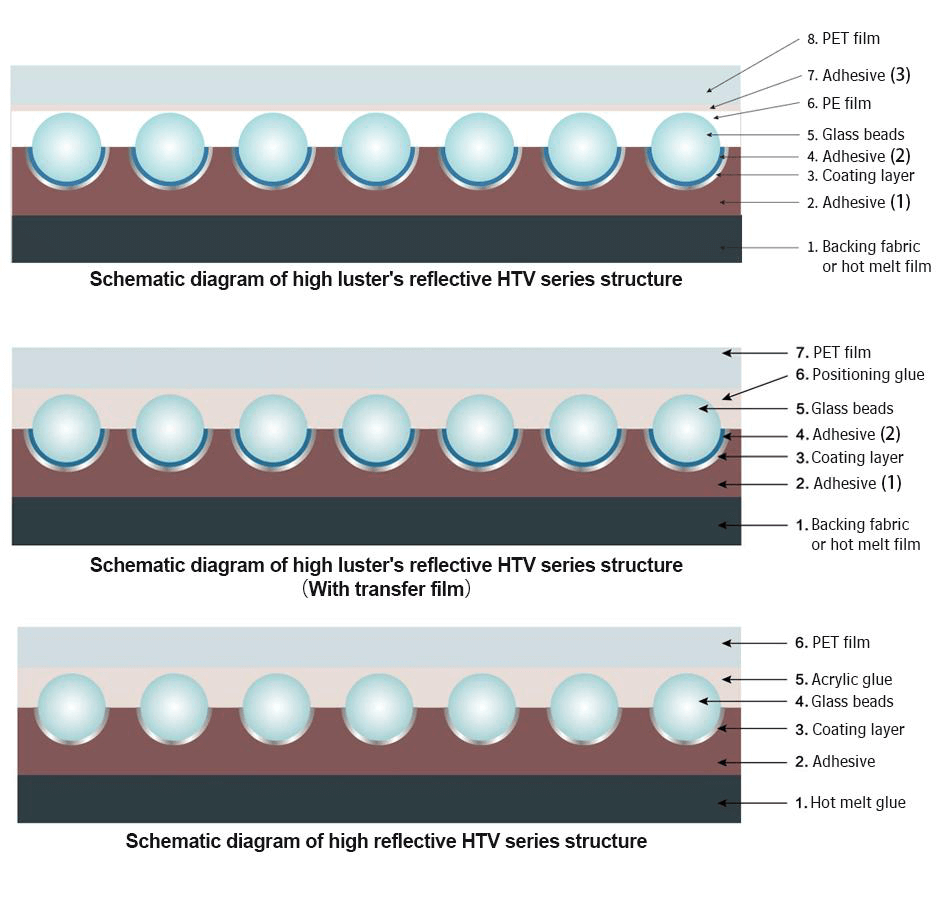

What are the main materials used by YGM to create Rainbow Reflective HTV?

For producing rainbow reflective HTV, there are several things that come into play.

1.Hot melt glue that may also contain the backing fabric such as PET or TPU.

2.Next comes the coating layer on the glass beads that provide reflectivity to the material.

3.The adhesive comes after to help the reflective material adhere to your material of choice.

4.All this sticks to glass beads.

5.It’s followed by the PET film.

6.The final coating may or may not contain adhesive.

Take a look at the following diagram to get a better view.

What should I know before ordering rainbow reflective vinyl? What are the most important things to keep in mind?

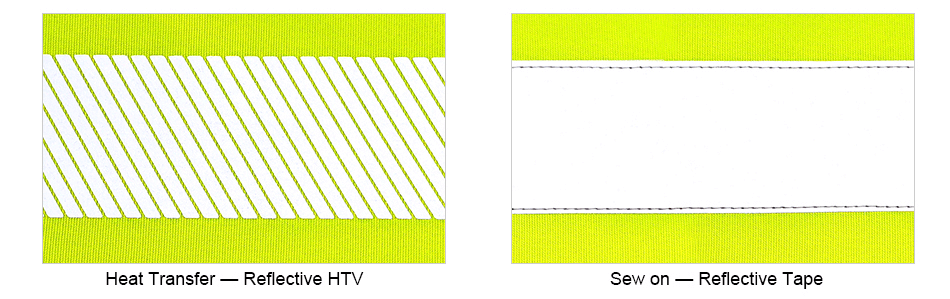

Once you’re ready to order the rainbow reflective HTV, it’s also important to get acquainted with the application process. First off, select if you want to apply as stripes or as a logo This is crucial to the ordering process because it’ll help you select the right type of rainbow reflective vinyl polymer.

- Stripes: For cutting in the striped-format, there aren’t many blade options available for you. Hence you should focus on a vinyl polymer type that’s good for hot-pressing onto the fabric.

- Logo: When it comes to logos, you can cut the material using a laser machine or a plotter. As for the former, it’s best for both PES and TPU backing while the plotter is best for PES backing as TPU is immensely sticky and gets stuck to the blade while you’re heating it up.

Next, compare the reflectivity, elasticity, flame retardancy, hardness, natural wear-and-tear resistance, and washing properties of the material prior to finalizing. When in doubt, feel free to get in touch with our customer service team and we’ll help you out right away.

Does YGM Manufacture Rainbow Reflective Heat Transfer Vinyl? Can I order Rainbow Reflective HTV from YGM?

Yes, YGM has extensive experience manufacturing holographic reflective heat transfer vinyl. That’s why you can order rainbow reflective heat transfer vinyl from YGM on any day, at any time. We have several facilities to accommodate your needs no matter how big or small it is.

Can I order a custom-size of Rainbow Reflective Vinyl? Are the specifications customizable too?

How long does it take for YGM to produce and deliver my order of Rainbow Reflective HTV?

Does YGM offer free samples for Rainbow Reflective Vinyl?

Making a final decision when it comes to a bulk order of rainbow reflective vinyl isn’t a cakewalk for most businesses. That’s why we want to cut down your hassles and help you make the right choice only after assessing the samples.

You can get free samples of rainbow reflective heat transfer vinyl material from YGM without any added costs. However, freight (shipping) charges are your responsibility; but that’s only until you order. In short, we will pay for the freight charges that you paid once you finalize the order by deducting the same from the grand total.

Are YGM products always available and in-stock? Do I need to pre-order and await new stock for months after ordering?

Yes, at YGM, we always ensure our advertised products are regularly in stock. You don’t need to wait for months for the new stock to appear once after ordering. This is exempt only if your order is rather large. Even in that case, we ensure your order is processed in less than a month.

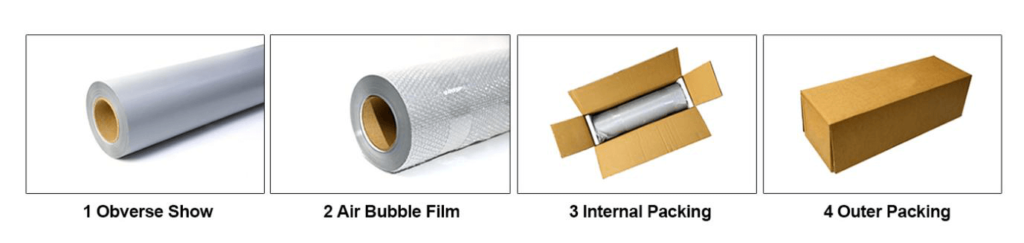

What type of packaging options do you offer at YGM?

When it comes to the packaging options available by YGM, we offer the rainbow reflective heat transfer vinyl in a rolled sheet format. Once after rolling the iridescent sheets, we also pack them in corrugated boxes that prevent denting and other damages to the reflective material. Moreover, this type of packaging also ensures you can stack up more material in the least amount of space, thus lowering freight charges too.

Don’t hesitate to specify if you have any different requirements of packaging and we’ll get right on it.

What is the total production capacity of YGM for rainbow reflective heat transfer vinyl?

Unlike wholesalers and retailers, YGM is a manufacturer of reflective reflective heat transfer vinyl. The same is why it’s nearly impossible for us to run out of stock when it comes to rainbow reflective heat transfer vinyl. We produce 3 million square meters of rainbow reflective HTV per month.

What are the chief quality control measures and standards used by YGM when it comes to rainbow reflective HTV?

Quality Control is the main focus of YGM as a reflective manufacturer mainly because our aim is safety and protection. Take a look at our core tenets of QC that makes it superior, foremost, and top-rated.

● Quality of the Surface

When it comes to rainbow reflective HTV, you’ll notice that the surface is absolutely seamless on our products. We assess it to ensure there are zero blemishes including black or white spots. You won’t find any tiny bubbles that arise from manufacturing defects, no matter which angle you look at it from.

● Reflective Quotient

Our products come with reflectivity exactly as advertised. Moreover, it’s easy to find out the reflection capabilities of the iridescent reflective fabric using gadgets that measure inverse reflection coefficient. The QC process ensures that every item comes with a reflectivity result of 40 to 60cd/lx/m².

● Release Force Efficiency

Popularly known as the adhesion force, the release force of a reflective heat transfer vinyl refers to the adhesive strength that’s present between the surface protection and the reflective layer. This is crucial when it comes to the process of hot-pressing or cutting out logos as the force may release at 90-degrees or 180-degrees based on the same.

To ensure the release force of the material you receive is the same as vouched here, cross-check with a Tensile Testing Machine. We do the same after the production of the material.

● Washing Performance

Certified with the ISO 15797 standard, our rainbow reflective heat transfer vinyl performs highly in the washing test specific for reflective heat transfer vinyl. Our products also come with the European certification of ISO 6330 of 40 to 60 degree celsius washing in addition to dry cleaning besides ordinary washing, hand washing and washing via industrial machines.

You don’t need to fret about getting confused because depending on the type and specification of rainbow reflective heat transfer vinyl you choose, we will also advise you on the washing requirements without fail.

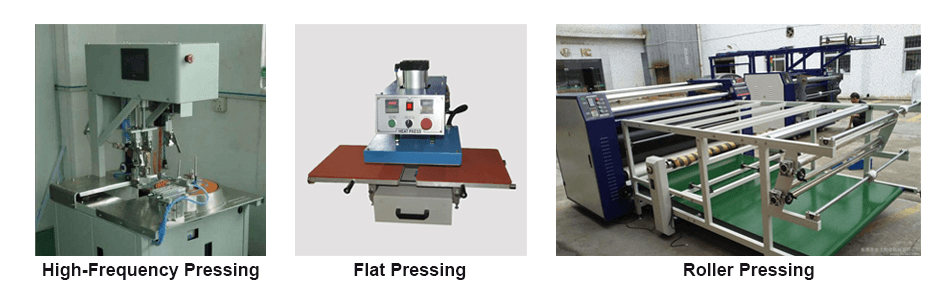

● Application

When it comes to pressing formats for using rainbow reflective HTV, you can use high-frequency pressing, roller pressing or even flat pressing. Also keep in mind to adhere to the operating suggestions as dictated by our team because fluctuations in machinery, raw materials and operational processes can differ from one another.

As a general note, the safe temperature for operating on the rainbow reflective HTV is below 200°C while the pressure must be less than 5 kg/cm².

What are the different certification standards when it comes to rainbow reflective HTV? How are they updated?

here are two central certification standards for rainbow reflective heat transfer vinyl material. Here’s more about them:

- EN ISO 20471: Divided into three different categories based on the risk zone, it needs to comprise fluorescent material (day and night visibility), reflective strips (night visibility), and contrast material. The most important mandates of this certification is the color of the base fabric, placement of tape and the least areas of reflectivity.

- Oeko-Tex Standard 100: When a product, especially in textile is tested and cleared for harmful or toxic elements, it gets the Oeko-Tex Standard 100 certification.

At YGM, we ensure that both these certifications are regularly updated.

Why is my rainbow reflective HTV not sticking when I apply it?

When you’ve followed all the right directions for applying rainbow reflective HTV and it still doesn’t stick, these are the things to keep in mind:

● Crosscheck Temperature, Time, and Pressure

It’s crucial buyers ensure that temperature, time and pressure are maintained to the dot when used rainbow reflective heat transfer vinyl. Once these are set appropriately, you must make sure the vinyl sticking direction is correct.

When it comes to temperature, not all vinyl polymer fabric adheres based on the same temperature. Before you finalize, test with the temperature recommended by the manufacturer first. On top of it, if you press or iron the rainbow reflective vinyl for a short or long time, it will fail to adhere properly. Keep in mind that prolonged pressing can often burn out the adhesion on the material.

If you’re wondering whether the pressure was right, the rule of thumb is if you need to physically shake your arms after doing a good press. Moreover, it’s possible to observe the weave of the material you’re applying rainbow reflective material to through the vinyl polymer. For instance, if you feel the household iron isn’t doing a great job, increase the weight ASAP.

● Type of Material

Always ensure the cloth you’re using for rainbow reflective HTV is right. For branding and logo, it’s best to use a PES kind of HTV while TPU is best if you’re using an elastic or spandex type of material.

● Problematic Accessories

Another common reason why rainbow reflective heat transfer vinyl or any vinyl polymer fails to stick properly owes it to seams, zips, buttons, or collars that are super-thick.

● Peeling the Right Way

Depending on the type of rainbow reflective HTV you’re using, it might require the film to be removed by peeling immediately after you hot press or iron it. For some others, cooling off might be required prior to removal of the carrier sheet in plastic. If you happen to peel the same wrongly, it can completely ruin the rainbow reflective design.

How to make rainbow reflective HTV adhere or stick better to the fabric I’m using? How can you ensure the heat transfer of rainbow reflective material sticks better on different surfaces?

One of the easiest materials to work with reflective HTV and when it comes to the iridescent type, you need to keep three things in mind as shown below.

- Confirm the type of fabric you want to hot press and crosscheck the temperature, time and pressure for application about the same.

- Make sure you follow the protocol while hot pressing before and after including the peeling-off of the protective film.

- Tweak the heat or press on the vinyl polymer in the rainbow pattern for up to 15 seconds to make sure the application is seamless and smooth.

What’s the maximum time rainbow reflective HTV will hold up?

When you’re thinking of reflective material, it needs to withstand natural wear and tear to hold up for long. That’s why rainbow reflective heat transfer vinyl polymers are a good bet for clothes, shoes and bags. It’s made to last longer than t-shirts if you take care of maintenance appropriately. Keep in mind to avoid scrubbing clothes and materials harshly to prevent the reflective polymer from wearing out.

How are rainbow reflective HTV tested and how do you check its quality?

Getting top quality material is important to us as much as you. To ensure you get the best of best, follow the checklist below:

- Check if the reflective surface is clean, smooth and blemish-free.

- Remove the protective layer of film and confirmif the presence of tiny glass beads on it.

- Once you engrave your business logo, it’s easy to remove the remnant material from the logo with ease.

- Check for wrinkles on the surfaces after you’re done with the hot press.

- You can also rub the surface using your palm or fingers to see if it drops glass beads.

How are rainbow reflective HTV tested and how do you check its quality?

If you ordered rainbow reflective heat transfer vinyl in wholesale, the next step is to ensure the material you ordered is of highest quality.

Here’s how to do so:

- Ensure there’s a separating space between the gray vinyl and the protective layer of film.

- Make sure glass beads aren’t falling off when you begin to tear the film that protects the rainbow reflective HTV.

- Try on a piece whether it’s easy to cut into a brand logo or strip.

- Do a trial wash on the rainbow reflective vinyl using your hand or the washing machine to ensure the standard of ISO 6330 is met with adequacy.

What’s the right way to cut rainbow heat transfer vinyl before application?

You can cut rainbow reflective vinyl polymers in several ways such as knives, cutting plotters, Cricuts, laser machines, computer-controlled gadgets and craft cutters. But, above all, there are two things to keep in mind as shown below:

● Cut into Strips

When you’re cutting by strips, you can use the plotter or the laser machine to make cuts as desired in rainbow reflective HTV, especially those with PES or TPU backing. These are easy to use and don’t need a complicated blade setting.

● Cut into Logos

If you’re cutting for logos, the requirement of professional props is a necessity. You can use a Silhouette Cameo 3, cutting machines or Cricut to help with the same. When doing so, open the design settings on your app that will let you use the computer for cutting into the reflective heat transfer vinyl and input the appropriate dimensions.

All you need to do next is mirror the design so that you’re making cuts on the vinyl polymer to the back before turning it around to add your fabric on which you need the reflective design.

What type of materials can you apply rainbow reflective heat transfer vinyl onto?

It’s not possible to apply rainbow reflective HTV on any material of choice. That’s because rainbow reflective vinyl is best to apply to flat surfaces that can take 120 to 140 degree celsius. Hence, the melting point has to be higher than 140 degree celsius. When you’re thinking of materials you can apply it to, keep in mind about the backing material of rainbow reflective heat transfer vinyl.

PES is a backing material that’s best for hot pressing on fabrics like polyester cotton, poly-cotton blends, nylon, wedding, etcetera. On the other hand, TPU is a backing material with high elasticity and ideal for material like leather, PVC and PU.

What are the popular applications and uses of rainbow reflective HTV today? Where can I use it?

Wondering where to use this exclusive iridescent fabric?

There’s a long list of options, but here’s our best bet to tickle your creativity:

- T-Shirts

- Caps/Hats

- Shoes

- Bags, handbags, backpacks

- Blouse/Tops

- Overall

- Jumpsuit

- Safety clothes

- Workwear

- Jackets/ Shrugs

What’s the right way to iron on rainbow reflective heat transfer vinyl on fabrics like shirts?

Are you thinking of using rainbow reflective heat transfer vinyl for turning shirts and tees into safe and stylish new inventions? Here’s all you need to do:

- Create an eye-catchy or brand-specific template on your system.

- Prepare your knife plotter or laser plotter that’s capable of cutting vinyl polymer.

- Make sure the carrier film is facing downwards.

- Peel away the extra vinyl polymer without disturbing your design from the carrier film.

- Keep the rainbow reflective vinyl polymer on the cloth you want to add it to.

- Ensure that the transparent area of the carrier material is pointing up.

- Proceed to 120 0C to 140 0C and apply pressure of up to 3kg per cm2for up to 15 seconds.

- When using a household iron, apply more than your usual pressure to make the rainbow reflective HTV stick better.

- Wait for 30 seconds to cool off.

- Now, peel out the carrier layer.

- If by any chance you see the design lift post your application, repeat the heat pressing process once more.

What is the right temperature for rainbow heat transfer vinyl during application?

When you stick to the right temperature, your rainbow reflective HTV has a better chance of sticking.

Here’s a rough reference:

- PESbacking at a temperature of 140 ℃ to 150 ℃.

- TPUbacking at a temperature of 130 ℃ to 140 ℃.

What’s the transfer pressure needed for rainbow heat transfer reflective?

You need to adhere strictly to the recommended pressure value according to the backing fabric as given below.

- PESbacking at the pressure range of 3 to 5 kgf.

- TPU backing at the pressure range of 2 to 4 kgf.

What’s the heat time required for rainbow reflective heat transfer vinyl?

To ensure the best quality of stickability for your rainbow reflective HTV, it’s crucial you follow the right heat time as shown below by your backing fabric selection.

- PES backing with a range of 12 to 15 seconds.

- TPU backing with a range of 12 to 15 seconds.

What’s the best way to peel heat transfer vinyl?

Do you know you can peel rainbow reflective HTV in hot or cold conditions? That being said, you should stick to the cold peel process if you want the best results.

How do I ensure the Rainbow Reflective vinyl remains at its best quality?

Keeping any fabric in it’s top condition is not child’s play. You need to follow the requirements and prerequisites to the dot. To ensure your rainbow reflective keeps at its best condition throughout its wear, keep a tight focus on the storage and timing of the adhesive component.

Basically it has a shelf life of over one year if you maintain the temperature between 15 to 30℃ and humidity of less than 60%.

What are the main differences between vinyl adhesive and rainbow heat transfer vinyl?

There are two main differences between rainbow reflective HTV and an ordinary vinyl adhesive material.

- Backing: Rainbow reflective HTV has a high-quality backing that comprises a plastic carrier material covering the top-side of the vinyl polymer. On the other hand, adhesive material made from vinyl may come in several hues and finishes, but contains a paper backing with a sticky texture, no matter which type you select.

- Application: The best thing about vinyl adhesive is it’s easy to stick directly. You don’t need to do anything more. But, when it comes to rainbow reflective heat transfer vinyl, you have to hot press in order to attach the vinyl polymer to the fabric of your choice.

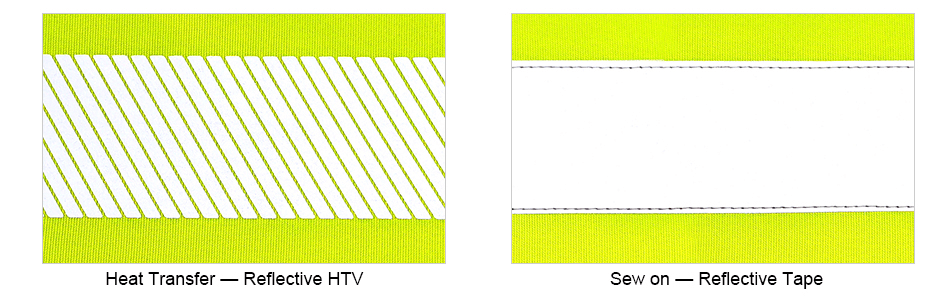

How do you differentiate rainbow reflective HTV from reflective tape for sewing?

Confused about the uniqueness between reflective tape and rainbow reflective heat transfer vinyl? Keep scrolling …

- Peel-Off: The main difference between the two is that the carrier sheet of rainbow reflective HTV is peeled once the hot pressing is complete unlike that of reflective tapefor sewing that’s peeled during the manufacturing itself.

- Backing: For the rainbow reflective material, the backing fabric is made of PES or TPU and for the reflective tapefor sewing, it’s usually 100% polyester, T/C, 100% aramid, 100% cotton or a combination of polyester and spandex (85% and 15%).

- Application: You can apply rainbow reflective vinyl via the hot press and it can be cut into a brand logo using a knife or a laser plotter. On the other hand, reflective tape for sewing is stitched onto the fabric.

What are the main challenges of using reflective heat transfer vinyl?

If you’re serious about investing in rainbow reflective HTV, the most important thing is to take a deeper look at its complications and shotcomings.

● Firmness

Rainbow reflective HTV isn’t firm on the fabric and is often layered. Note that the hot pressing parameters (Time, Temperature, and Pressure) are optimum besides maintaining 15 to 30 degree-celsius and humidity less than 60% for keeping a shelf life of one year. Also cross check whether the fabric you’re about to hot press the rainbow reflective vinyl has been treated for water resistance and oil.

● Layer of adhesion

When the temperature and pressure aren’t optimum, the glue layer will disintegrate in other cases.

● Glass beads falling out

You will notice the glass beads falling out from the reflective HTV when the pressure applied isn’t enough or the curing time of the adhesive of the rainbow reflective HTV isn’t ideal.

● Uneven sticking

The vinyl polymer can get stuck to the logo and fail to peel off properly. This happens only when you haven’t set the power of the machine you used to cut the logo improperly. Set it right and the vinyl will stick better.

● Damage of the transfer coating

When the transfer coating film tears off once you’re done with hot pressing application of the rainbow reflective HTV, the fault lies with the curing time of the glue. If you disturbed it too soon, this can be a common problem. Another reason might owe it to the lack of intensity.

● Improper depth of glass beads

You might also notice that the glass beads may be embedded too deeply into the fabric. This is a common cause of the lack of force when you’re peeling the transfer film off.

Is it possible to apply rainbow reflective heat transfer vinyl when it’s wet? If not, why?

No, you should never apply a rainbow reflective HTV polymer to a wet surface. That’s because all types of reflective HTV have a metallic layer that’s made with aluminum to prevent the airing capabilities.

Now, when you apply rainbow reflective vinyl to a wet surface, it prevents the moisture from getting away to the surface. That being said, you might’ve to apply such a reflective material to hot and humid surfaces such as that of a vehicle, especially when you can’t bring it down to cold temperatures. In such a case, slight wetness is permitted. Nevertheless, try your best to eliminate moisture as much as possible like by using a squeegee.

Also keep in mind that applying rainbow reflective heat transfer vinyl to wet surfaces automatically voids the warranty of the product. Because the wet surface will ruin the pH balance of the iridescent reflective vinyl polymer, it’s not the manufacturer’s fault.

Wetness also adversely affects the metallic layer of reflective heat transfer vinyl often leading to rust and depreciation of the core material.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang