- info@cnygm.com

- +(0)86-576-88122360

Zhejiang YGM Lab Tour

YGM Reflective specializing in manufacturing reflective material, luminous material, optical variation material, temperature variation material, thermal isolation material, UV resistant material, and derivative products for 15+ years.ENISO 20471 & ANSI 107 certificated.

In-house testing equipment:

1.Inverse reflection coefficient measuring instrument

Used to measure the retro-reflecting coefficient of reflective products at different angles (Incident Angle β& Observation Angle α).Before use, calibrate the instrument with a standard template,set the angle values to be measured (Incident Angle β& Observation Angle α), and then align the measuring port of the instrument with the surface of the object to be measured for measurement.The unit is cd/lx/m².

2.Aging test chamber

The xenon arc lamp that can simulate the full sunlight spectrum of nature is used to reproduce the destructive light waves existing in different environments, so as to carry out accelerated tests on light resistance and weather resistance of reflective materials.It can simulate rain, temperature, humidity, condensation and other environmental factors to achieve a combined test, and reproduce the hazards occurred in the outdoor for months or even years within a few days or weeks.

3.Washing machine

Used for washing test of reflective fabric in ISO6330 standard and industrial washing resistance in ISO15797 standard.Add proper amount of special laundry detergent according to the standard, set the washing conditions, take out the washed sample for drying after washing, then observe the surface of the sample and measure the retro-reflecting coefficient after washing and keep the sample.

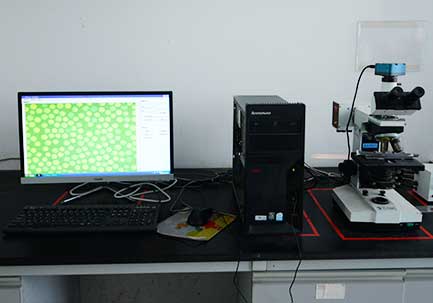

4.Micro analyzer

Used for micro-structure analysis of reflective products,that is, the distribution and size of glass beads.Place the prepared sample on the carrier plate, align it with the center of the aperture, turn the coarse and fine quasi-focal spiral until the object image is clear, and the distribution of glass beads can be clearly seen on the connected computer screen.

5.Small vacuum coating machine

Used for the coating test of different media on the surface of the reflective product microbeads. The test is carried out under high vacuum and is divided preheating, vacuuming and coating stages.Heating the diffusion pump to about 190℃, then crude pumping and fine pumping to make the vacuum chamber pressure reach 5*10^(-2)Pa,turn on the evaporation button to evaporate the surface components of the microbeads in the form of radicals or ions, and settle on surface to form different reflection effects.

6.Computer type desk type tensile testing machine

Used for testing the initial adhesion,90°peeling force, 180°peeling force and silk thread breakage of reflective sheeting.Before the test, install different measuring fixtures according to the different test items, fix the sample on the fixture, select the corresponding test type on the computer to measure and record the relevant data.

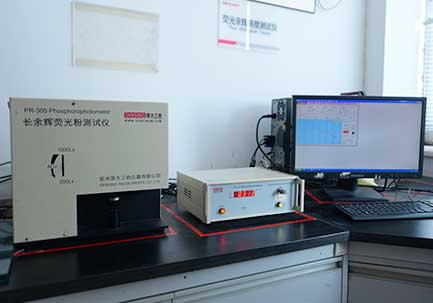

7.Long afterglow fluorescent powder tester

Used for testing the fluorescence afterglow brightness of luminescent products.Place the luminous product in the illuminance of 1000±50lx, illuminate for 5 minutes and then place it under dark conditions for measurement. Set the sample name, measurement time or cut-off brightness on the connected computer. After starting the measurement, the afterglow brightness data change and the corresponding curve will be displayed on the screen.

8.Pneumatic ironing machine

Used to hot press the heat transfer vinyl products to different fabrics. Before use,select the appropriate hot pressing parameters (temperature, time, pressure) according to the different heat transfer vinyls and fabrics. After the hot pressing is finished,tear off the surface protective film after cooling.

9.Test compound machine

Used for small test recombination and heat transfer printing process.Adjust the temperature, pressure and speed according to the type of composite product, put the composite material flatly between the two rollers, press the “Lower Roll Up” button, just press the end of the composite material, and then press “Up Roll Rotation” button to start compounding. When the compounding is finished, press the “Pause” button to take out the material.

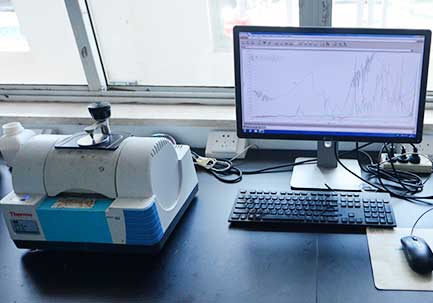

10.Infrared spectrometer

The infrared absorption spectrum of the molecule is obtained by recording the energy level transition process caused by the molecular vibration after the substance absorbs the radiation energy. Used to analyze the molecular structure and chemical composition of the product.The measuring range is 4000cm-1 ~400cm-1. Instrument environment requirements: ambient temperature 18~25℃, relative humidity ≤60%.

11.Dry cleaning machine

Used for dry cleaning ISO3175 standard test of reflective fabric.Place the sample in the sample room and add an appropriate amount of tetrachloroethylene dry cleaning agent.Set the dry cleaning time.After the dry cleaning is completed,dry and deodorize the sample,then observe the surface condition and measure the retro-reflecting coefficient.

12.Constant temperature and humidity room

Under constant temperature and humidity, conduct environmental simulation tests on the physical and other related characteristics of reflective products.Can simulate low temperature, high temperature, high and low temperature changes, constant damp heat, high and low temperature alternating damp heat and other conditions to meet various needs of customers.Temperature range: -40℃~+150℃, humidity range: 20% ~ 95% RH.

13.Hydraulic Tester

Used for measuring the hydrostatic pressure of fabrics.Select the pressurization method, set the increase rate to 6kpa/min, and the test unit mmH2O/pa/kpa. After filling the sample tray with water, press the clamp down to clamp the assembled fabric sample and start the test. When three complete drops of water appear on the surface of the fabric sample, stop the test and record the value. Cycle test, measure 5 sets of data, take the average.

14.Fabric air permeability meter

Used to test the air permeability and moisture permeability of fabrics.The air permeability meter can measure air permeability:0.1~12000mm/s, fabric thickness:≤15mm. Under the same conditions, the measurement should be repeated at least 10 times in different parts of the same sample.The moisture permeability meter uses the moisture permeable cup moisture absorption method to measure the ability of water vapor to penetrate the fabric.

15.Fabric Flame Retardant Performance Tester

Used to measure the flame spread of the reflective fabric in the vertical direction under a limited fine flame combustion under the GB/T 5455-1977 standard,to determine the flame retardant performance of the reflective fabric.Hang the sample vertically in the box, set the ignition time and adjust the flame height to 40mm±2m, observe the combustion state of the sample, record the afterflame time and smoldering time, and calculate the damage length.

16.Laser Particle Size Distribution Meter

The particle size distribution of solid powder or emulsion is tested according to the physical phenomenon that the particles can scatter the laser.Finally the particle size distribution table, particle size distribution curve, average particle size, etc. can be obtained.Measuring range: 0.1μm-340μm.Measuring principle: Mie scattering theory.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang