- info@cnygm.com

- +(0)86-576-88122360

REFLECTIVE HEAT TRANSFER VINYL

Your Trustworthy Reflective Heat Transfer Vinyl

Manufacturer Supplier

Your Reliable Reflective Heat Transfer Vinyl Supplier

Multiple Types | Customized Stripes & Logos

- PES TPU backing are available for plotter or laser machine.

- Different functions: decoration, elasty, luminescent flame retardant based on your Own needs.

- Good washing performance,home wahing or industrial washing are both accepted.

- Customized design based on your Own application.

- 18 years+ Focusing on Manufacturing and Supplying Reflective Tape And Safety Clothing .

- ISO 9001, ISO14001, ISO18001, ISO16949, EN ISO 20471, EN11612, EN14116, EN469, EN14119,OEKO Certificated.

- Every Roll of Reflective Material Products is traceable.

- 500+ staffs,40 production lines,8 workshops ,3 R&D dept.

- Monthly 2 Mil PCS safety apparel & 5Mil SQM reflective fabric.

Reflective Heat Transfer Vinyl Feature

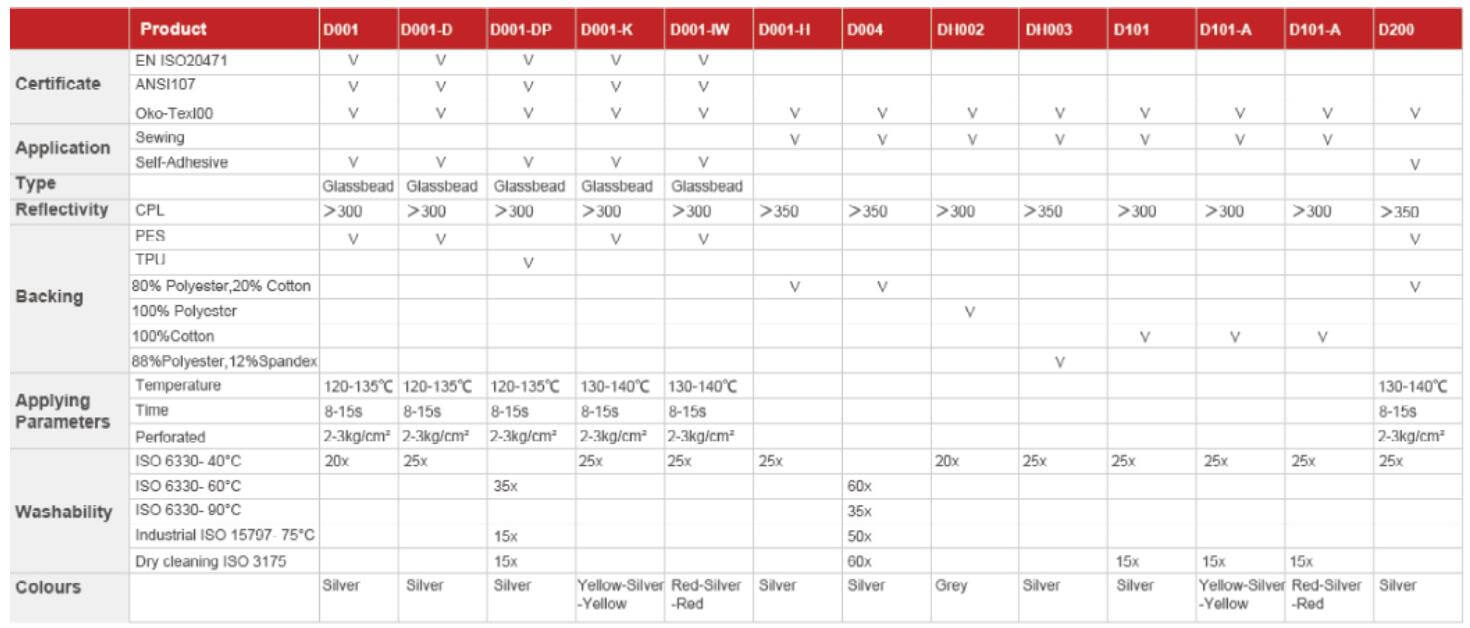

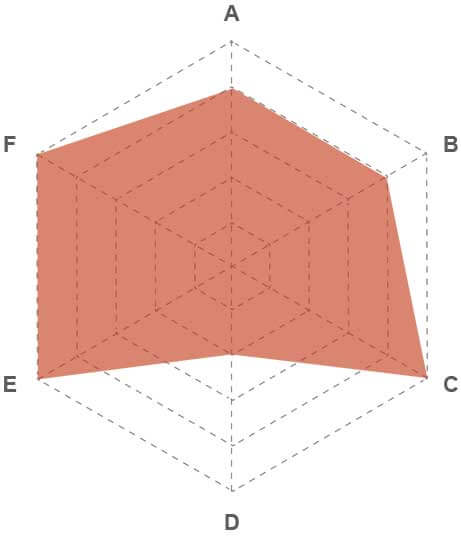

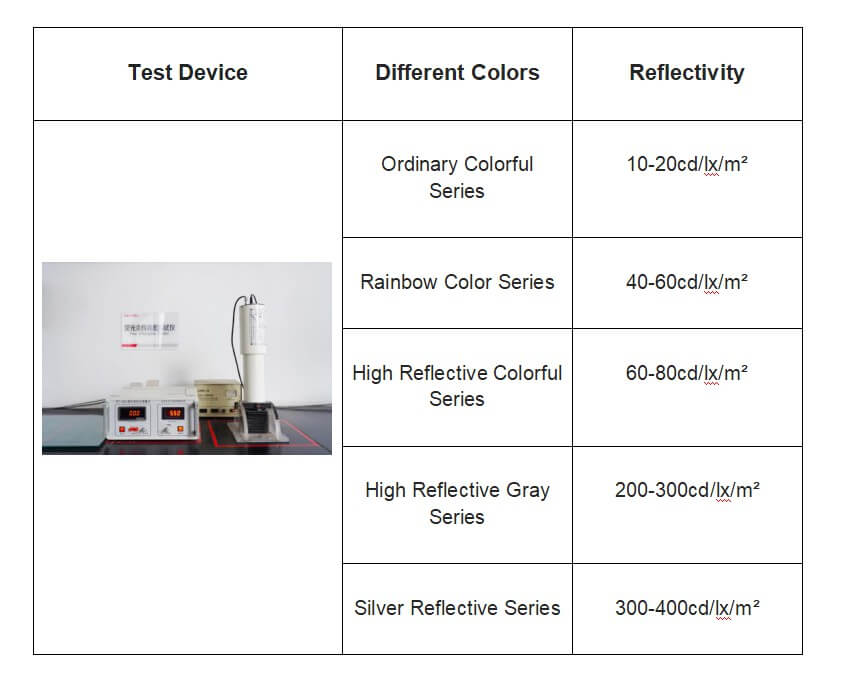

A:Reflectivity

This Reflective Heat Transfer Vinyl comes in different colors with varied reflectivity. -Silver displays a reflectivity of 300-400cd/lx/m² -Gray shows a reflectivity of 200-300cd/lx/m² Highly reflective colors show up with 60-80cd/lx/m² -Rainbow color reveals 60-80cd/lx/m² -Ordinary colors are built with a reflectivity of 10-20cd/lx/m²

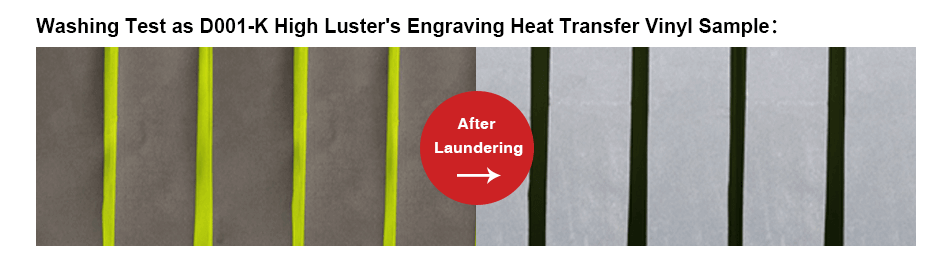

C:Washability

When it comes to reflective HTV fabric, there are three options for washing. You can conduct home wash, do industrial wash, or do dry cleaning, depending on your necessity and preference. This fabric has a washability of up to 50 cycles.

E:Customizability

If you want your Reflective HTV to be unique and branded, there are many ways to do so. The first way is to subject it to laser-cutting. Another method is to cut it into stripes according to the graphics needed. You can also cut in the same way for logos. In this case, it’s easy to customize the size and color too.

B:Color

When it comes to luster and sheen, different colors have different reflectivity. The highest reflecting colors are Silver, Yellow/Silver/Yellow, and Red/Silver/Red, followed by Grey color. The lowest reflecting colors comprise of ordinary colorful series of any color.

D:Flame retardancy

The ability to reflect fire for HTV fabric is high too. But such an ability is only found in few colors. Flame retardancy of Reflective Heat Transfer Vinyl is seen with the color arrangements Yellow-Silver-Yellow, and Red-Silver-Red.

F:Applicability

Where can you use Reflective HTV? One of the many applications includes hot pressing on fabrics like T-Shirts, Hats, Bags, Caps, or other textiles. You can also use it via laser-cutting or knife-cutting the logo of your brand and other graphics based on fashion needs.

Why choose YGM Reflective Heat

Transfer Vinyl?

Our factory

Today almost after 16 years, YGM proudly boasts over 40 production lines, 500+ staff, eight facilities, and a giant factory that accommodates the faculty and the facility in Taizhou, Zhejiang.

|  |  |

| R&D Center With over three R&D centers, YGM leads the list for being one of the most creative reflective manufacturers from China. Our cutting-edge research center in Taizhou is built with innovation in focus. We are proud to have up to 15 engineers closely working on research and development. | Workshop With a vast factory boasting 30 production lines and five facilities within, YGM employs hundreds of well-qualified personnel. It stretches over 30,000-50,000 square meters over Binhai Industrial Park in Taizhou Economic Development Zone. | Warehouse Equipped with all the facilities to undertake the manufacturing and storage of millions of reflective material from vests to fabrics, sheetings, tapes, and everything reflective, our warehouse is one of the best in the country. |

Certifications

YGM is equipped to maintain high-quality owing to the many certifications under our sleeve. We keep upgrading our processes to seek higher certifications every few months.

|  |  |  |

| TUV Referred to a TÜV/GS Rheinland certification, this is a German security and safety standard. It means that the product is safe by electrical safety, undesired noise, and dangerous components. Established to ensure protection in the early 19th century, it conducts audits for providing certifications. | UL A kind of product certification, UL (Underwriter’s Laboratory) certification translates to standards adhering to national safety and free of risks associated with fire and electric shocks in specific environments (Division II). UL is a globally-acclaimed testing, auditing, inspecting, and validation body. | Oeko-Tex Standard This is a certification often conducted for ensuring high quality of textiles. She standard 100 of Oeko-Tex checks for harmful substances and ensures textiles don’t contain any of them. It means that every inch of the reflective fabric sold to you is free of harmful substances. It helps to protect the planet and your workers wearing it. | ISO The primary certifications from the International Organization for Standardization with YGM are ISO 20471, ISO 9001, and ISO 14001. Out of this 20471 stipulates the safety standards for workwear concerning high-risk situations. ISO 9001:2015 is the standard for general quality management, management responsibility, resource management, product realization, and more. ISO 14001 consists of performance requirements concerning environmental management systems (EMS) of the factory. |

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Reflective HTV Category

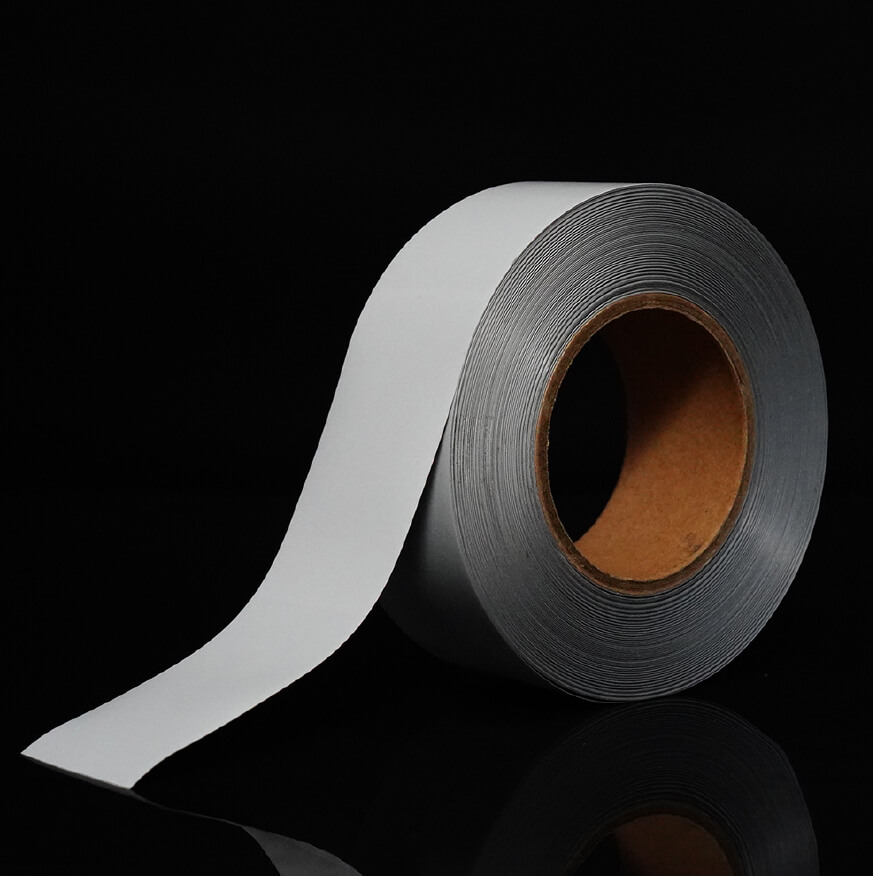

High Luster's Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:PES/TPU

Hot Pressing Temperature:125-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:PES type is suitable for hot pressing on woven, cotton, etc.TPU type is suitable for hot pressing onto the fabric as PU or PVC, etc.

High Luster's Engraving Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:PES

Hot Pressing Temperature:125-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Good air permeability. Suitable for lettering and then hot pressing on woven, cotton and other fabrics.

High Luster's Industrial Wash Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Hot Pressing Temperature:110-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:High washing performance. Suitable for hot pressing onto the fabric as PU or PVC, etc.

High Luster's Flame Retardant Elastic Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Hot Pressing Temperature:110-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Good flame retardancy and elasticity. Suitable for elastic and flame retardant fabrics.

High Luster's Elastic Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Hot Pressing Temperature:110-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Super good elasticity. Suitable for hot pressing onto the fabric as PU or PVC, etc and various elastic woven tapes.

High Luster's Printable Reflective Heat Transfer Vinyl

Reflectivity:>400CPL

Color:Silver

Backing Fabric:PES

Hot Pressing Temperature:130-140℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Printable reflective heat transfer vinyl can be used for direct surface printing. Suitable for lettering and then hot pressing on woven, cotton and other fabrics.

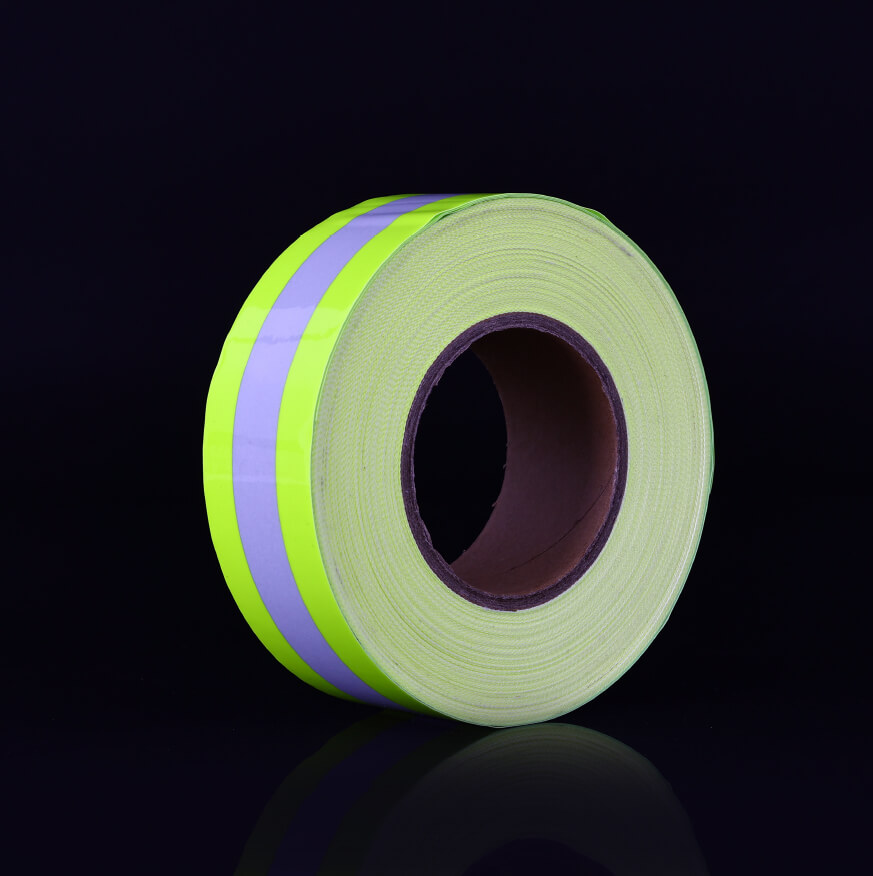

High Luster's Fluo-Yellow Warning Reflective Heat Transfer Vinyl

Reflectivity:>300CPL

Color:Yellow-Silver-Yellow

Backing Fabric:PES

Hot Pressing Temperature:130-140℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:High flame retardancy and heat resistance. Suitable for working fields of fire protection and electrical industry. Ideal for hot pressing on woven, cotton and other fabrics.

High Luster's Fluo-Red Warning Reflective Heat Transfer Vinyl

Reflectivity:>300CPL

Color:Red-Silver-Red

Backing Fabric:PES

Hot Pressing Temperature:130-140℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:High flame retardancy and heat resistance. Suitable for working fields of fire protection and electrical industry. Ideal for hot pressing on woven, cotton and other fabrics.

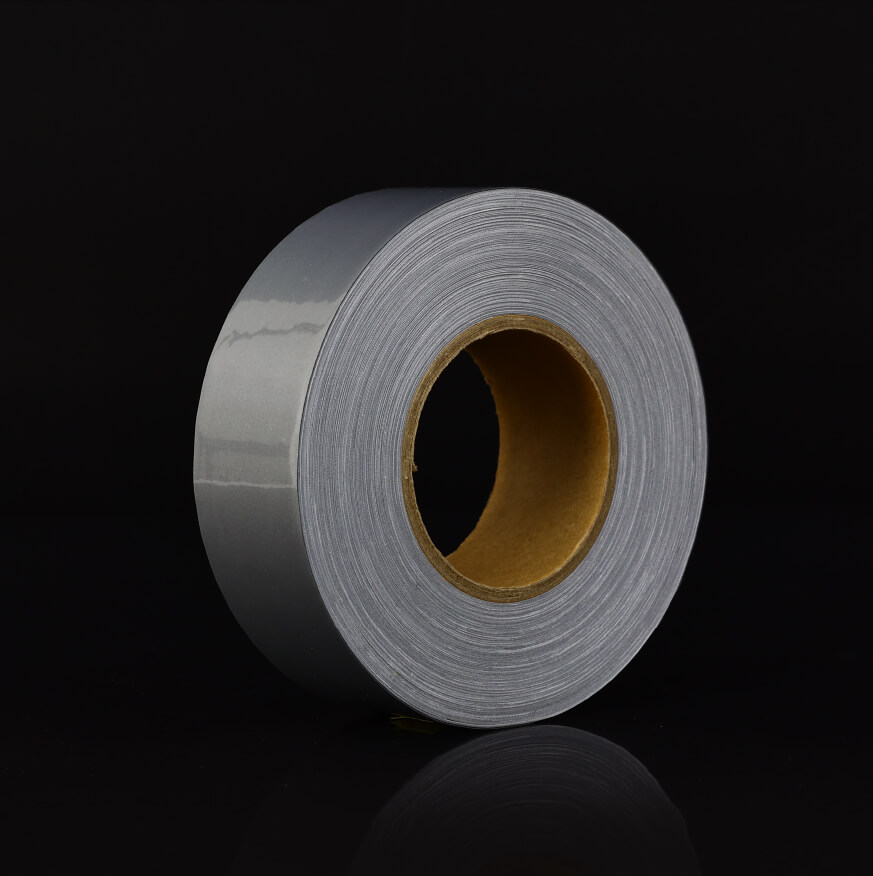

High Reflective Heat Transfer Vinyl

Reflectivity:>300CPL

Color:Grey

Backing Fabric:PES

Hot Pressing Temperature:120-130℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Suitable for hot pressing onto the fabric as woven, cotton, etc.

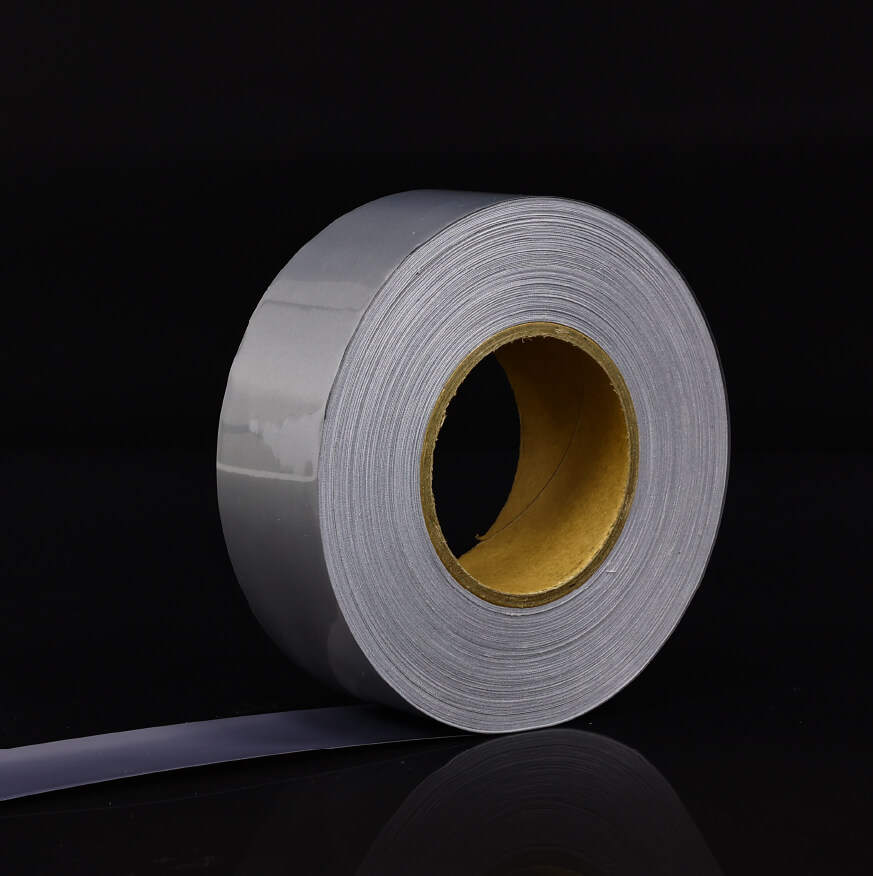

High Reflective Engraving Heat Transfer Vinyl

Reflectivity:>300CPL

Color:Grey

Backing Fabric:PES

Hot Pressing Temperature:125-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Good air permeability. Suitable for lettering and then hot pressing on woven, cotton and other fabrics.

Colorful Reflective Heat Transfer Vinyl

Reflectivity:>15CPL

Color:Any color

Backing Fabric:PES

Hot Pressing Temperature:130-150℃

Hot Pressing Time:10-15s

Hot Pressing Pressure:3-5kg/cm²

Application:Suitable for hot pressing onto the fabric as woven, cotton, etc.

Rainbow Reflective Heat Transfer Vinyl

Color:Rainbow color

Backing Fabric:PES

Hot Pressing Temperature:140-150℃

Hot Pressing Time:15-20s

Hot Pressing Pressure:3-5kg/cm²

Application:Suitable for hot pressing onto the fabric as woven, cotton, etc.

Table of Contents

Reflective Heat Transfer Vinyl:

The Complete Buying Guide

Why do you need reflective heat transfer vinyl?

Reflective Material Products are manufactured and refined from reflective materials like reflective fabric, reflective sheeting, PVC reflective fabric, reflective thread, reflective woven/oxford tape, reflective heat transfer vinyl, reflective pattern fabric, etc.

Reflective Material Products play a crucial role in road traffic safety, outdoor safety and are also a prime mirroring of fashion personality. An array of reflective products including reflective logos, reflective clothing, reflective accessories, reflective caps, reflective gloves, reflective vests, reflective jackets, reflective school uniforms, etc.are now a growing market.

Reflective heat transfer vinyl is a supreme reflective material with an ideal amalgamation of beauty, safety, and fashion. The reflective heat transfer vinyl has the following benefits:

1. Non-Destructive– Reflective heat transfer vinyl is a non-destructive and smooth product that does not cause any damage to the function of the carrier during application. For instance, you can directly hot-press the reflective vinyl onto the waterproof fabric. This will not damage the waterproof performance of the material. Moreover, thereafter you do not need to conduct any auxiliary treatment for waterproof reflective tapes.

2. Diversity of Processing– You only need a laser machine or a cutting plotter to engrave design patterns on reflective heat transfer vinyl.

3. Flatness– Compared to silk-screen printing, various patterns and stripes on reflective heat transfer vinyl are smoother, more compliant, and aesthetically appealing when they are hot-pressed onto the fabric.

4. More Dynamic– Reflective heat transfer vinyl is, therefore, more dynamic and chosen by many popular sports brands like Nike, Adidas, etc., as an embellishment of fashion and vogue for all their sportswear and sports shoes.

Quality Standards for Reflective Heat Transfer Vinyl

1. Surface Color– The reflective heat transfer vinyl usually has silver, gray, and different traditional colors like red, yellow, green, etc., and a rainbow hue. However, the surfaces are all seamless. There are no black spots, white spots, or even tiny bubbles on the surface from various angles.

2. Reflectivity– All colors have different reflectivity levels. The darker the color, the lower the reflectivity (you can accurately detect the reflection level with professional equipment like inverse reflection coefficient measuring instruments). You can refer to the data given below.

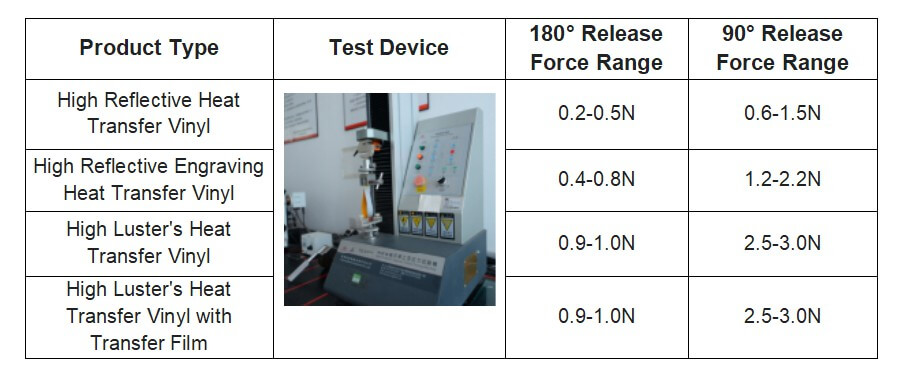

3. Release Force– Release force is also known as adhesive force. The release force implies the adhesion strength between the reflective layer and the surface protective layer. It is also a critical indicator for monitoring the application of hot pressing or cutting logos—the force releases at either 90 degrees or 180 degrees angle. You can analyze this with the help of a Tensile Testing Machine. For instance-

Remarks: Different reflective material products have different release forces; they, especially, have transfer film and non-transfer film.

4. Washing Performance– ISO15797 Industrial Washing is the top-performing wash for reflective heat transfer vinyl. Then, there is also the European standard ISO6330 washing (40°/60°C) and dry cleaning, some of which are ordinary, washing machine, hand washing. Depending on the different nature of the reflective heat transfer vinyl chosen by the consumer, the directions for washing will be clarified.

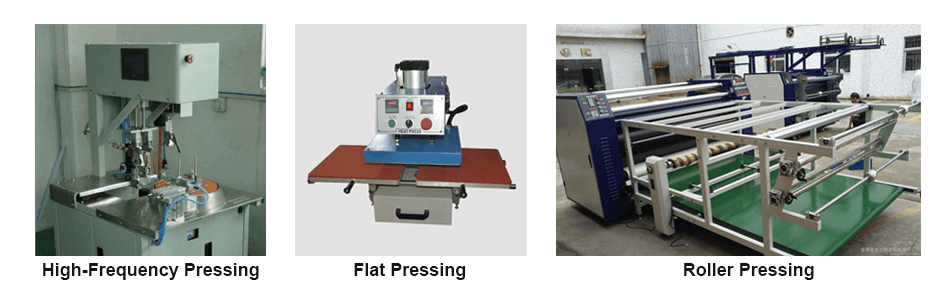

5. Pressing Method– High-frequency pressing, flat pressing, and roller pressing are the different pressing methods available. Due to variations in machinery, material, and operating environments, please adhere to the operating requirements suggested by our organization for suitable modifications. The safe operating temperature of the reflective heat transfer vinyl is <200°C and the pressure is <5kg/cm².

What are Common Applications for Reflective Heat Transfer Vinyl?

Reflective Heat Transfer Vinyl has many uses because of its unique quality. Here are some of the references:

| Product Name | YGM Model Number | Application | Reference processing conditions | ||

|---|---|---|---|---|---|

| Hot Pressing Temperature(℃) | Pressure | Time | |||

| High Luster’s Heat Transfer Vinyl | WD001 | Especially suitable for hot pressing on polyester, webbing, T/C, or other fabrics and safety clothing. For example, cut into strips or various logos. | 130-150 | ﹥2kg/cm² | 12-15s |

| D001M | |||||

| D001 | |||||

| D001-D | |||||

| D001-GS | |||||

| D001-FT | Especially suitable for shoes and bags because the material itself is scratch-resistant and wear-resistant. | 130-150 | |||

| High Lusters PU Heat Transfer Vinyl | D001-P | Suitable for hot pressing on PU and PVC fabric. It can only be scrubbed with water, not soaked in water and machine washed for a long time. | 120-130 | ||

| D001-DP | ( D0001-DP has scratch-resistance) | ||||

| High Luster’s Lettering Heat Transfer Vinyl | D001-K | Especially suitable for lettering, engraving patterns, etc., and then hot pressing on fabrics such as polyester, webbing, T/C. | 130-150 | ||

| High Luster’s Elastic Heat Transfer Vinyl | D004-7D | Especially suitable for hot pressing on general elastic fabrics. | 130-150 | ||

| D004-7P | Especially suitable for hot pressing on elastic bands or high elastic fabrics. | 120-130 | |||

| High Luster’s Flame Retardant Heat Transfer Vinyl | D001-H | Especially suitable for hot pressing on flame retardant fabrics, with average washing performance. | 130-130 | ||

| D001-H-GS | Especially suitable for hot pressing on flame retardant fabrics with high washing requirements. | 130-150 | |||

| D001-H-GS | 130-150 | ||||

| DH102-12 | 130-150 | ||||

| Colorful Series Heat Transfer Vinyl(High Luster’s and ordinary reflective) | D201-X | Especially suitable for lettering, engraving patterns, etc., and then hot pressing on fabrics such as polyester, webbing, T/C. | 130-150 | ||

| High Reflective Heat Transfer Vinyl | D101-A | Suitable for hot pressing on fabrics such as polyester, webbing, T/C. | 130-150 | ||

| D101 | Suitable for hot pressing on fabrics such as polyester, webbing, T/C. | 130-150 | |||

| High Reflective Lettering Heat Transfer Vinyl | D101-K | Especially suitable for lettering, engraving patterns, etc., and then hot pressing on fabrics such as polyester, webbing, T/C. | 130-150 | ||

Can you apply wet reflective vinyl?

No. You should never apply wet reflective vinyl. Reflective Heat Transfer Vinyl has an Aluminium (metallic) layer that prevents airing capacity. Hence, when you use the material wet, it does not allow the moisture to escape the surface. Sometimes, you may need to apply it wet- for example, on a dark vehicle surface in a hot and humid climate, when the surface cannot be brought down to cooler temperatures. In this case, you need to use minimum wet solutions. However, you should make every attempt to remove as much moisture as possible when using a squeegee.

Please note that wet applications will void any warranty for the product. The wet solution used will overthrow the pH balance of the reflective heat transfer vinyl.

Moreover, it may also greatly affect or react with the aluminum layer, leading to corrosion and breakdown of the material. Also, the adhesive quality of the material will be greatly compromised during wet applications.

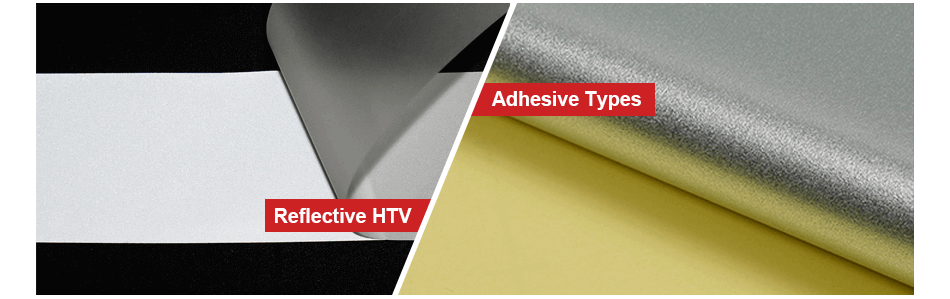

How do you tell the Difference Between Adhesive and HTV Vinyl?

1.Different Backing-

Adhesive types of vinyl come in all forms of colors and finishes. However, they always have the same paper backing and are sticky to touch when the backing is peeled off.

On the other hand, reflective HTV does not have a paper backing. Instead, reflective HTV has a clear plastic carrier sheet that covers the top of the vinyl.

2.Different Usage-

You can stick the vinyl adhesive directly. But for the reflective HTV vinyl, you need hot-press to attach the HTV and the fabric.

How to Test the Quality of Reflective Heat Transfer Vinyl?

- Observe whether the reflective surface is smooth or there are spots on the surface.

- Tear off the protective film and check if there are any glass beads on it.

- After engraving the logo, check if you can easily weed off the extra material from the logo.

- After hot pressing reflective HTV, check if the surface is wrinkled. Also, try rubbing it with your fingers to see if it drops glass beads.

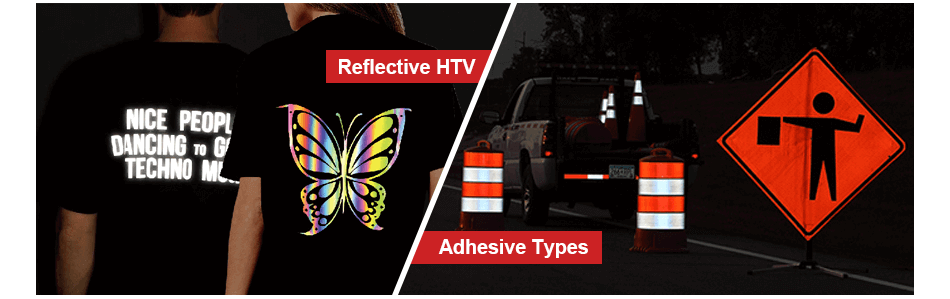

How do you use Reflective HTV?

Reflective HTV is used for safety and beauty, depending on the industry in which it is used. Reflective Heat Transfer Vinyl is safety-certified. Policemen, firemen, and other security personnel use it on their uniforms. Reflective HTV shines bright in the night and hence, distinguishes these personnel in the dark. You can also iron on reflective vinyl; hot press the designed pattern on the clothes, shoes, and bags to make them unique.

The reflective HTV used for safety uniforms is usually cut into strips with customizable width. After deciding on the strip size, you can iron on reflective vinyl strips and hot press them according to the specified temperature, time, and pressure. Finally, after cooling, you can tear off the protective film from the surface.

Additionally, you can also cut the reflective HTV into logos or any other pattern of your choice. Once you finish the cut, weed out the excess material from the reflective heat transfer vinyl and iron on the reflective vinyl design that you carved. Set your iron to the cotton ironing mode and press for about 15-20 seconds, and make sure to cover the entire design. Finally, allow the carrier sheet to cool for a few seconds before removing it. And you are done! Your new reflective design is all ready to wear and shine!

What is Reflective Heat Transfer Vinyl?

Reflective heat transfer vinyl, or reflective HTV, is a specialized vinyl polymer that can be used on some fabrics and surfaces to manufacture patterns and advertising objects. It comes in a roll or sheet package with an adhesive backrest so that it can be trimmed, weeded, and placed on a substrate for heat application. Reflective heat transfer vinyl is manufactured in single colors and also has unique choices such as rainbow color.

What Should I Know Before Ordering Reflective Heat Transfer Vinyl?

When you think of ordering reflective heat transfer vinyl, you should first know how to do it, by stripe or logos. I am referring to the application field, which is very essential for the selection of appropriate reflective HTV.

If you cut it into stripes, there are not too many blade criteria; just find an appropriate reflective HTV to hot press on the fabric.

There are two options when you cut it into logos. One is through a laser machine, PES, TPU reflective HTV are both available, so you can plan it yourself. The other one is for the plotter- it’s easier to pick the PES backing; since the TPU is sticky, it’s trapped on the blade during heating.

After selecting the appropriate backing, consider reflective efficiency, washing, elasticity and flame resistance. You see, we’ve got a lot of heat transfer vinyl in various functions. Just follow the recommendations, and you’re going to pick the one you really like, so it’s okay to ask us to help. You will need to remember the material efficiency criteria, such as washing performance, elasticity, hardness, wear resistance, etc.

How do you cut Reflective HTV?

The first time you get the heat transfer vinyl, you might think of two ways to use it. One of them is cut to strip, the other is cut to logos. For strip cutting, which is not too much of a blade prerequisite, both the plotter and the laser machine may be used to cut heat transfer vinyls that are in PES or TPU backing. It’s much easier to operate. For logo cutting, we need more professional equipment, such as Silhouette Cameo 3, Cricut, or other cutting machines. In your computer cutting app, you open the design, scale it to the correct dimension, and then mirror the design. You need to mimic the pattern so you’re cutting the heat transfer vinyl back and you’re going to turn it back the other direction as you add it to your shirt.

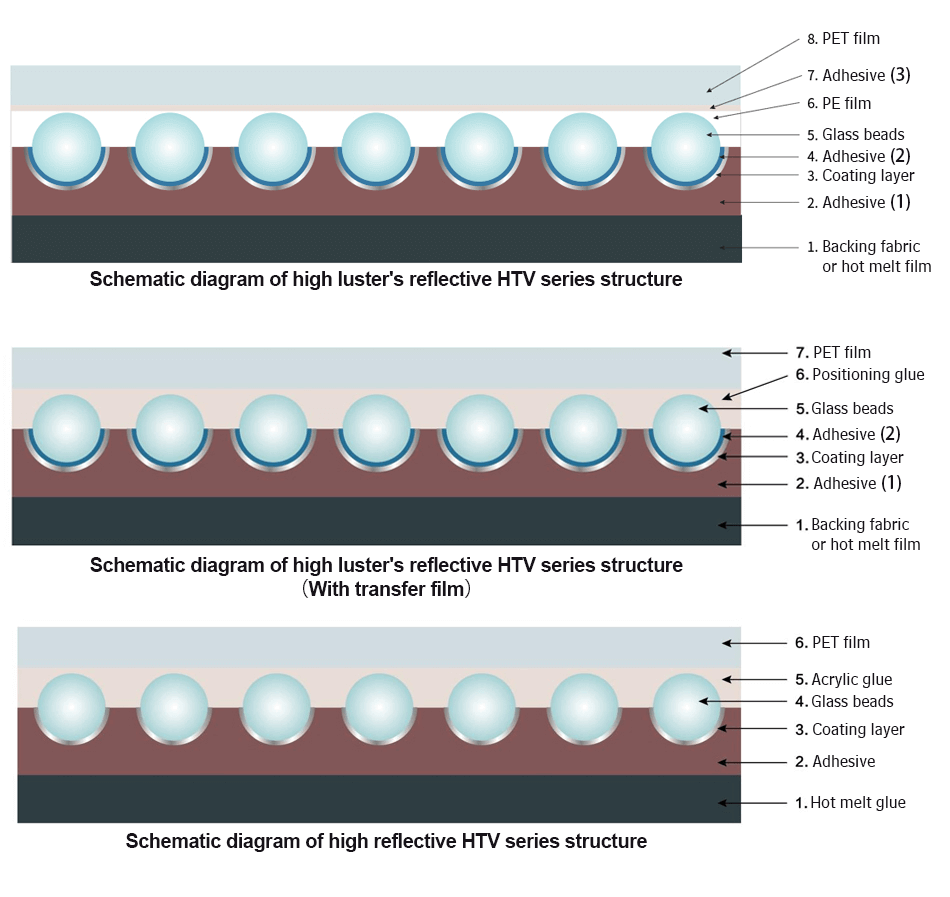

What is the use of the Transfer Film in the Reflective HTV?

1. The transfer film prevents logo movement. The transfer film is sticky and transparent, making hot pressing more comfortable and convenient.

2. Transfer films prevent cloth biting. The material of an ordinary protective film is PET+ PE. The PE melts at a higher temperature and sticks to the fabric. The transfer film is made of PET only, so that it does not melt at higher temperature.

3. Some customers need a transfer film for other usages.

How can I Ensure the Quality of Reflective Heat Transfer Vinyl?

1. Check if there is a separation between the protective film and the gray vinyl.

2. Observe the surface for any glass beads that fall off when you tear off the protective film.

3. Test whether it can be used by cutting it into a logo or a strip.

4. Put the reflective HTV through a washing test, either machine or hand wash, as per the ISO6330 standard to check its fastness.

How can I make my Reflective HTV stick better?

1. Find out what kind of fabric you’re using and what your heat transfer vinyl product is; know the best hot pressing temperature, pressure and time.

2. Hot press the heat transfer vinyl to the cloth under the right conditions; following completion, peel off the protective layer after cooling.

3. Shift the heat down a little and press the pattern for around 12-15 seconds, making sure the vinyl is fully smooth.

Why is my Heat Transfer Vinyl not Sticking?

1. Check that all criteria are fulfilled: time, temperature, and pressure are all incredibly critical considerations when using HTV; check for directions on the vinyl you are using, and make sure all settings are correct.

● Time: Pressing or ironing for too short a time will cause vinyl not to adhere to your goods; ironing the heat transfer vinyl for too long will burn the adhesive off.

● Temperature: Not all vinyl is used at the same temperature. Test to make sure you use the recommended temperature.

● Pressure: Good pressure is when you physically shake your arms from pressing down so hard, you should be able to see the weave of the cloth through the vinyl. If you’re not sure whether you’re getting enough pressure from your household iron, throw a little more weight behind it.

2. Check what kind of cloth you’re hot pressing the vinyl on. To cut a logo, use PES type heat transfer vinyl, and for spandex fabric use TPU type. Just be confident that whichever comes first, the jersey or the vinyl, they’re going to fit together.

3. Thick seams, buttons, zips, or collars may all be the root of the problem.

4. Some types of HTV may require the carrier to be peeled off right after you pressed or ironed it on. Others might need you to cool off entirely before you remove the plastic carrier sheet. Peeling inappropriately will certainly destroy your design.

How Well Does Heat Transfer Vinyl Hold up?

Iron-on vinyl will last longer than the T-shirt itself, depending on which form of heat transfer vinyl you are using. Always remember to turn your clothes inside out and wash them cold. Do not scrub hard.

What is the Suitable Material to use HTV Reflective on?

HTV is ideal for hot pressing on flat surfaces at 120-140°C, so the melting point of the material can be greater than 140°C. HTV has two major types of backing material: TPU and PES.

TPU type has strong elasticity and is primarily applied to elastic fabrics such as PU and PVC; PES type is mainly used for hot pressing on webbing, polyester cotton, nylon, etc.

You can check the feature comparison of TPU and PES given below.

| PES | TPU | |

|---|---|---|

| Composition | polyester | thermoplastic polyurethane |

| Transparency | white translucent | transparent, translucent, matte |

| Elasticity | general | very good |

| Soft and comfortable | general | very good |

| Washing | very good | general |

| Dry cleaning | very good | general |

| Temperature resistance | good high temperature resistance | good low temperature resistance |

| Hot pressing temperature | 140-150℃ | 130-140℃ |

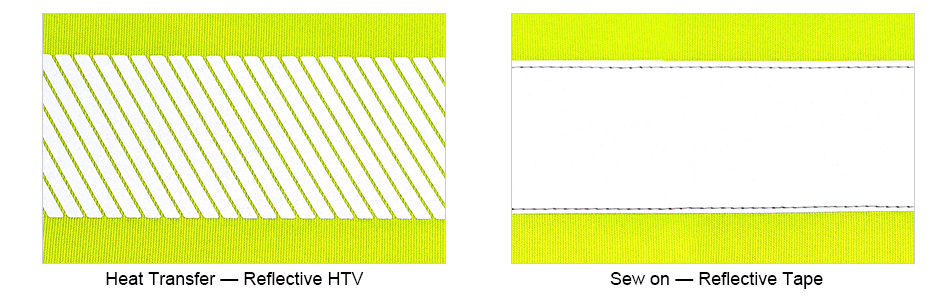

What is the Difference Between Reflective HTV and Reflective Tape for Sewing?

- The carrier sheet (PET film, PE/PET composite film, or clear safety film) of the reflective HTV is peeled off after hot pressing and the carrier sheet of the reflective tape is peeled during the manufacturing process.

- The reflective HTV substrate is made of PES and TPU (hot melt adhesive film), while the reflective fabric substrate is made of 100% polyester, T/C, 100% cotton, 100% aramid, and 85% polyester+15% spandex.

- Reflective HTV is applied during hot pressing of garments and fabrics. It can be cut into various logos with a knife and a laser plotter (customized logos are available); the reflective fabric is used for the stitching of safety clothing. And after surface water-repellent application, it can also be used to create reflective umbrellas.

How do you Iron on HTV?

1. Build a template on your computer.

2. Use a knife plotter or a laser plotter to cut vinyl (with the transparent layer of carrier sheet facing down).

3. Weed away the excess of vinyl, leaving your design on the carrier layer.

4. Place the vinyl on your cloth (transparent layer of carrier sheet facing upwards), heat press at 120°C-140°C, press 2-3kg/cm² for 12-15 seconds. If you’re using a home iron, press it under strong pressure.

5. After 30 seconds of cooling off, softly peel off the carrier layer. If any areas of design lift after application, heat press the areas again.

What Problems Do Consumers Usually Face When Using Reflective HTV and What are the Reasons?

1. Layered

● The Reflective HTV is not firm on the fabric.

If the hot pressing temperature, time, and pressure are correct.

Pay attention to the usage timing and storage condition of hot melt adhesive; Temperature: 15-30℃, humidity: <60%, shelf life: 1 year.

Whether the fabric has been treated with oil and water resistance.

● Hot melt adhesive and glue layer.

Temperature and pressure are inappropriate.

2. Glass Beads Falling

The glue curling time is not up, or the strength is not enough.

3. After the logo was cut, the extra vinyl stuck to the logo, and it could not be peeled off perfectly.

The power of the logo cutting machine is not set perfectly.

4. After the hot pressing was finished, the reflecting portion was removed when the transfer film was torn off.

The duration of the glue curing is not enough, the intensity is not up.

The peeling force of the transfer film is too strong.

Glass beads are embedded too deep.

What Temperature Should the Heat Press be Set on for HTV?

For various HTV reflective backing materials, the hot pressing criteria are different. As for your reference as follows:

| Backing Fabric | Hot Pressing Temperature | Hot Pressing Pressure | Hot Pressing Time |

|---|---|---|---|

| PES | 140-150℃ | 3-5kgf | 12-15s |

| TPU | 130-140℃ | 2-4kgf | 12-15s |

Note: Due to variations in hot pressing devices, fabrics and operating environments, please adhere to the recommended processing conditions for necessary changes.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang