- info@cnygm.com

- +(0)86-576-88122360

Your Reliable Iron On Reflective Tape Supplier

Multiple Types | Customized Stripes & Logos

- YGM Reflective is one of the best Iron On Reflective Tape manufacturer in China.

- We offer different types of Iron On Reflective Tape that will suit your needs on safety clothing.

- As a SO 9001, EN ISO 20471, and OEKO certified company, YGM manages and control the quality of our products before delivering to our customer.

- YGM manages and control the quality of our products before delivering to our customer.

- Send us your inquiries now!

Iron On Reflective Tape Features

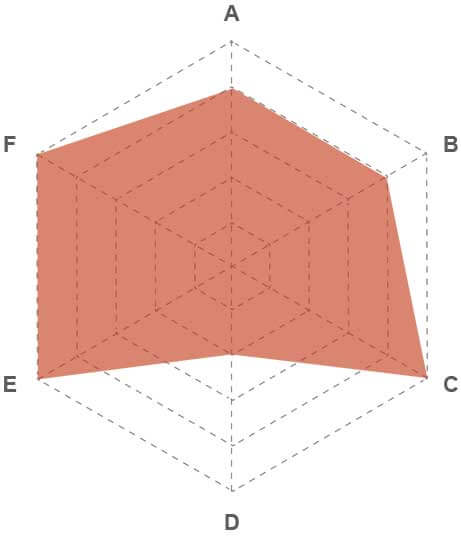

A:Reflectivity

The reflectivity of the tape is the factor that distinguishes it from the regular tapes

C:Washability

As the HTV tapes are used for hot pressing on fabrics, it is imperative that they will require cleaning.

E:Customizability

As the HTV tape can be used for various clothing applications, it is highly customizable.

B:Colour

The major application of the Iron On Reflective Tape is in fabrics. This is the reason this tape is of various different colours such as:

D:Flame retardancy

The ability to resist fire is known as flame retardancy. And when it comes to the Reflective Tape Iron On, not all of its variants are flame retardant.

F:Applicability

The applicability of the Iron On Reflective Tape is wide. It is pretty easy to understand that if the tape is used for hot pressing on fabrics, it will surely have a wide range of applications.

Why choose YGM Iron On Reflective Tape?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Iron On Reflective Tape Category

High Luster's Heat Transfer Vinyl

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: PES/TPU

Hot Pressing Temperature: 125-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: The PES variant is suitable for hot pressing on woven, cotton, etc., whereas the TPU type tape is suitable for hot pressing onto the fabric such as PU, PVC, etc.

High Luster's Engraving Heat Transfer Vinyl

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: PES

Hot Pressing Temperature: 125-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: The engraving HTV has excellent air permeability. Hence, it is suitable for lettering and then hot pressing on woven, cotton and other fabrics.

High Luster's Industrial Wash Heat Transfer Vinyl

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: TPU

Hot Pressing Temperature: 110-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: This HTV has a high washing performance which makes it suitable for hot pressing onto the fabrics like PU or PVC, etc.

High Luster's Flame Retardant Elastic Heat Iron On Reflective Tape

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: TPU

Hot Pressing Temperature: 110-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Excellent flame retardancy and elasticity. It is best suited for elastic and flame retardant fabrics.

High Luster's Elastic Iron On Reflective Tape

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: TPU

Hot Pressing Temperature: 110-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Best fit to be used on elastic clothes. Suitable for hot pressing onto the fabric as PU or PVC, etc. and various elastic woven tapes.

High Luster's Printable Iron On Reflective Tape

Reflectivity: >400 cd/lx/m²

colour: Silver

Backing Fabric: PES

Hot Pressing Temperature: 130-140℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Printable Iron On Reflective Stripes is best for direct surface printing. Moreover, it can also come handy for lettering and then hot pressing on woven, cotton and other fabrics.

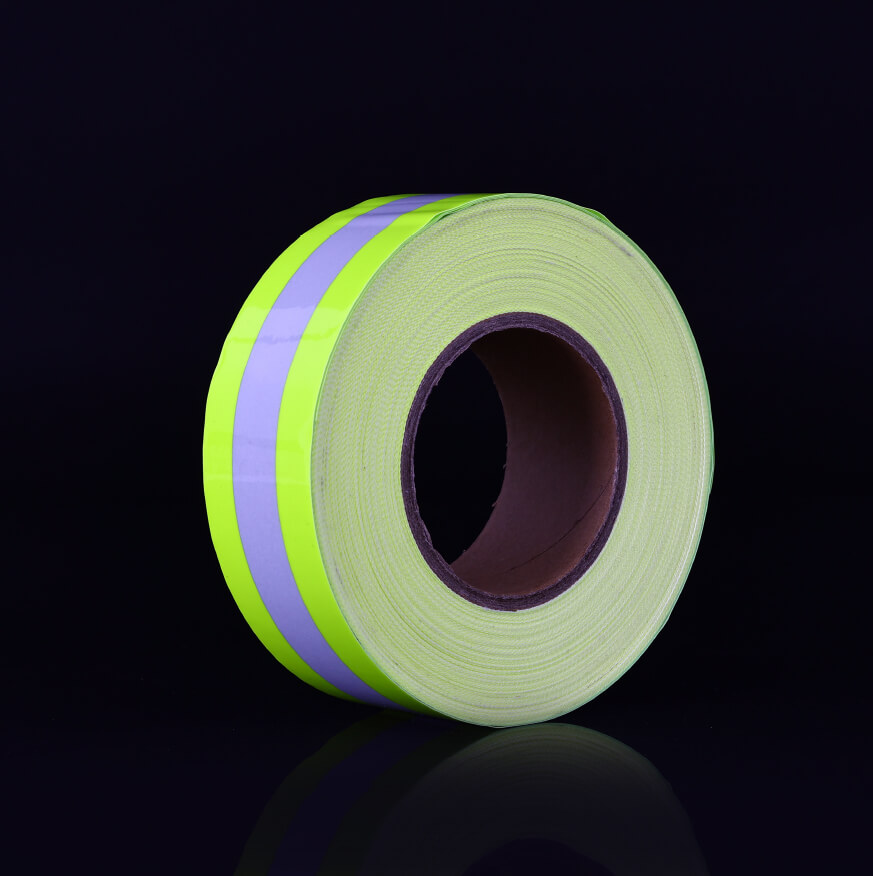

High Luster's Fluo-Yellow Warning Iron On Reflective Tape

Reflectivity: >300 cd/lx/m²

colour: Yellow-Silver-Yellow

Backing Fabric: PES

Hot Pressing Temperature: 130-140℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Highly flame retardant. Perfect for working fields of fire protection & electrical industry. Ideal for hot pressing on woven, cotton and other fabrics.

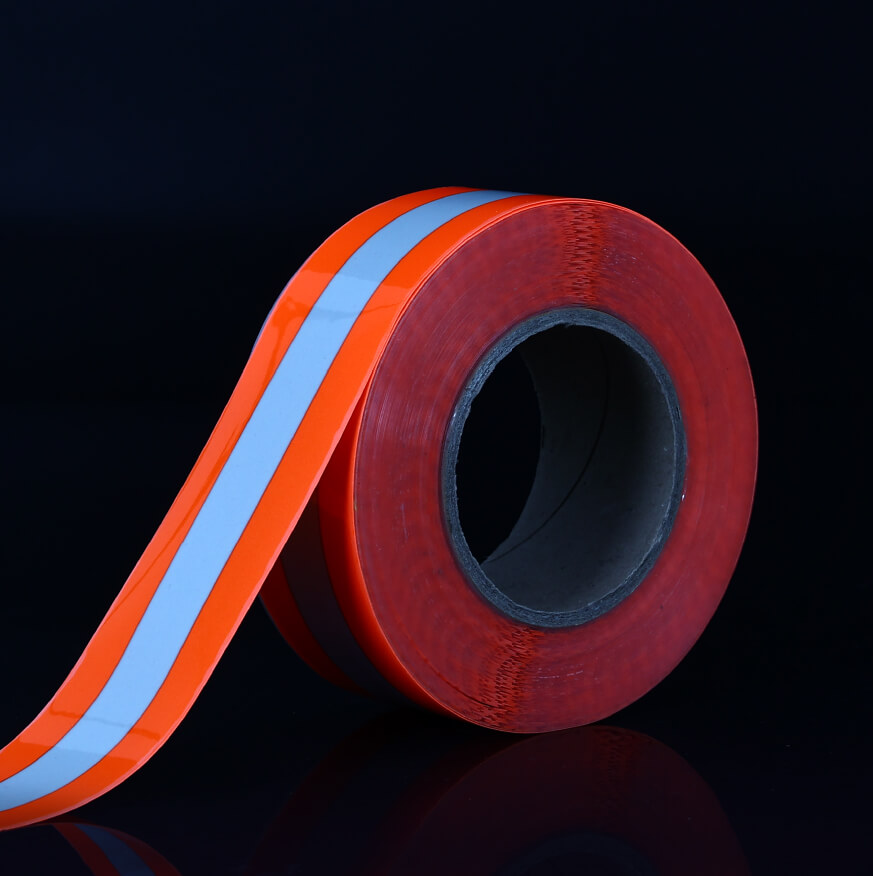

High Luster's Fluo-Red Warning Iron On Reflective Tape

Reflectivity: >300 cd/lx/m²

colour: Red-Silver-Red

Backing Fabric: PES

Hot Pressing Temperature: 130-140℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: This HTV variant is highly flame retardant and heat resistant. Moreover, it is good for working fields of fire protection and electrical industry.

High Iron On Reflective Tape

Reflectivity: >300 cd/lx/m²

colour: Grey

Backing Fabric: PES

Hot Pressing Temperature: 120-130℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Ideal for hot pressing onto the fabric as woven, cotton, etc.

High Reflective Engraving Iron On Reflective Tape

Reflectivity: >300CPL

colour: Grey

Backing Fabric: PES

Hot Pressing Temperature: 125-135℃

Hot Pressing Time: 8-15s

Hot Pressing Pressure: 2-3 kg/cm²

Application: Just like highly lustrous tape, this HTV tape also has good air permeability. And this makes it suitable for lettering and then hot pressing on woven, cotton and other fabrics.

Colourful Iron On Reflective Tape

Reflectivity: >15CPL

colour: Any colour

Backing Fabric: PES

Hot Pressing Temperature: 130-150℃

Hot Pressing Time: 10-15s

Hot Pressing Pressure: 3-5 kg/cm²

Application: This tape has less reflectivity, but it is suitable for hot pressing onto the fabric as woven, cotton, etc.

Rainbow Iron On Reflective Tape

colour: Rainbow colour

Backing Fabric: PES

Hot Pressing Temperature: 140-150℃

Hot Pressing Time: 15-20s

Hot Pressing Pressure: 3-5 kg/cm²

Application: Ideal for hot pressing onto the fabric as woven, cotton, etc.

Iron On Reflective Tape: The Comprehensive Buying Guide

Table of Contents

What is Iron On Reflective Tape?

Among the other reflective tapes, the heat transfer vinyl has a unique utility. First off, it is a specialized vinyl polymer with a strong hot melt adhesive backrest that helps in fixing it to the surface. Moreover, it has a customizable structure which makes it easy to cut and trim it to form various shapes like logos, strips, etc.

You can cut the heat transfer vinyl tape either by a knife or by laser and use it on fabrics or any other surface for uses as an advertisement. If it is the reflectivity factor that concerns you, the Silver colour HTV tape has the maximum reflectivity. On the other hand, highly reflective colours that have a combination of Silver also deliver significant reflectivity.

The HTV tapes are precise of 12 types grouped into 3 series, namely:

- High luster’s reflective HTV series

- High luster’s reflective HTV series with transfer film

- High reflective HTV series

The structures of all three are different that will be discussed further on this page.

Why do you need reflective HTV?

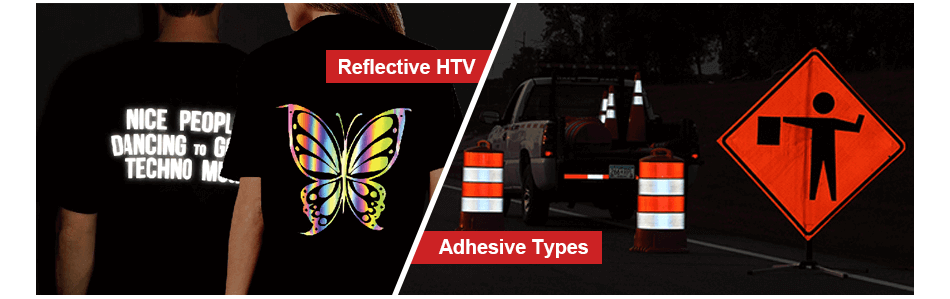

The use of reflective products is on the rise. And with time, there are many reflective products that have surfaced before us, such as reflective fabric, reflective sheeting, PVC reflective fabric, reflective thread, reflective woven/oxford tape, reflective HTV, reflective pattern fabric and many more!

With the increase in the number of reflective products, the application scope of these products has also widened. For instance, reflective products like tapes can be used in safety clothing, protective clothing, advertisements, road safety signs, etc.

The Reflective HTV is one of the prime products that is widely needed by the industries, especially the fashion clothing industry. Why? Well, the clear reason for this is high customizability, reflectivity and a wide range of applications. Moreover, there are some add-on benefits of the tape that makes it fit for diverse uses:

Easy Processing

At first, it may seem like the tape is not that easy to handle. But, when you will use it, you will be delighted to know that the processing of HTV is pretty easy. The tape can be easily cut into desired shapes and patterns using a laser cutting machine or a cutting plotter. If you are not having any of this equipment, you can cut it with a knife. However, the cutting precision may be less.

Excellent Finishing

The finishing of the reflective tape describes how well the tape looks after it is hot-pressed on the fabric. And in the case of reflective HTV, the finishing is way better than the regular silk-screen printing. The Iron On Reflective Tape is smoother, compliant and looks absolutely brilliant when hot-pressed onto the fabric.

Non-destructive

While being easy to process and having superb finishing, the reflective HTV is also a non-destructive product. Its complex design makes it immune to any kind of damage while hot pressing onto the fabric. Both reflectivity and waterproof performance of the reflective HTV stay intact after it is applied to the fabric.

Diverse and Dynamic

So far, it is clear that the reflective HTV has diverse applications, right. Now, apart from this, the tape is also dynamic. This is because it is used by some of the top brands of the world like Nike, Adidas in making their prime products like sports shoes and other sports gear.

All these benefits are the key pillars that support the importance and need of the reflective HTV.

Quality Standards for Iron On Reflective Tape

When it comes to the quality of the Reflective Tape Iron On, we at YGM make sure that we test all our products with top-quality equipment to produce the finest ones. And if we talk about the quality standard of Iron On Reflective Tape, there are many parameters to analyse. Here are all of them in detail:

Reflectivity

As all the major applications of the Iron On Reflective Tape are affected by the reflectivity factor, YGM tests the reflectivity of all the tapes using an ingenious device, analyse, inverse reflection coefficient measuring instruments.

As all colours have different reflectivity, the quality testing of all the colours gave us the following results:

Surface Colour

The surface colour test is done to check if the surface of the reflective HTV has the required colour retention. As it is available in numerous colours like red, yellow, green, silver, grey and rainbow hue, it is necessary to verify.

As per our professional testing methods, the surface of the HTV is made free from black spots, white spots, tiny bubbles, scratches, etc. Thus, making our Reflective Tape Iron On ideal for its required application.

With YGM, you can be free from the fear that your tape will lose its colour easily. There will not be any kind of colour difference, no matter from which angle you are observing.

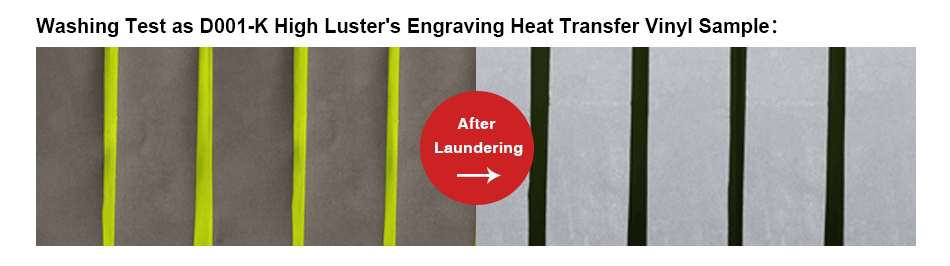

Washing Performance

As HTV tapes are of various types and most of them are used for hard pressing onto the fabrics for multiple applications, it is pretty clear that they will need washing from time to time. To ensure that the tapes you purchase from us can be used for long even after washing repeatedly, we suggest you wash them as per the provided directions.

The HTV tapes produced by YGM can be washed using three methods, namely,

Industrial Washing: ISO15797 Industrial Washing is the best performing wash for Iron On Reflective Tape.

Apart from this, there is ISO6330 European standard washing and dry cleaning too. Some of these are hand washing methods, machine washing methods and ordinary washing methods.

The washing method varies based on the type of tape. Hence, make sure you get this thing clarified before purchasing the product.

One crucial thing to note about the HTV tape is that it loses its reflectivity by some amount after some washes. For instance, the high luster’s engraving HTV tape loses its reflectivity by 15 cd/lx/m2 after 15 cycles of washing at 40-degree celsius.

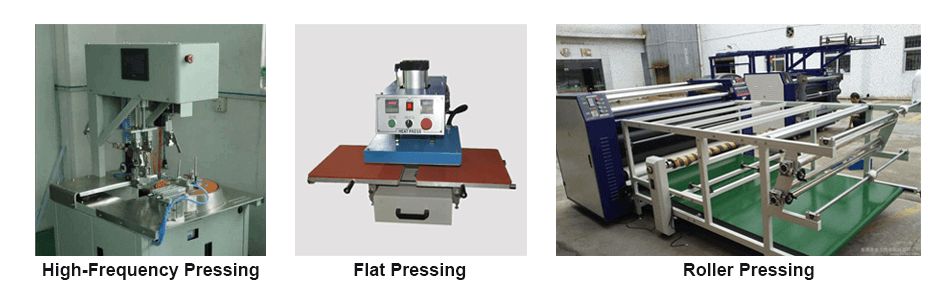

Pressing Method

To get the optimum output after pressing the tape on the required fabric, it is necessary to ensure that you are using the right pressing method. If you are purchasing the HTV tape from YGM for the purpose of pressing on fabrics, it is necessary to learn about the pressing methods like:

- High-frequency pressing

- Roller pressing

- Flat pressing

Other than the pressing methods, it is important to keep in mind the material and operating environment of the tape. For instance, each of the tapes has a particular operating temperature and pressure. The safe operating temperature of the Iron On Reflective Tape is less than 200°C, and the pressure is less than 5kg/cm².

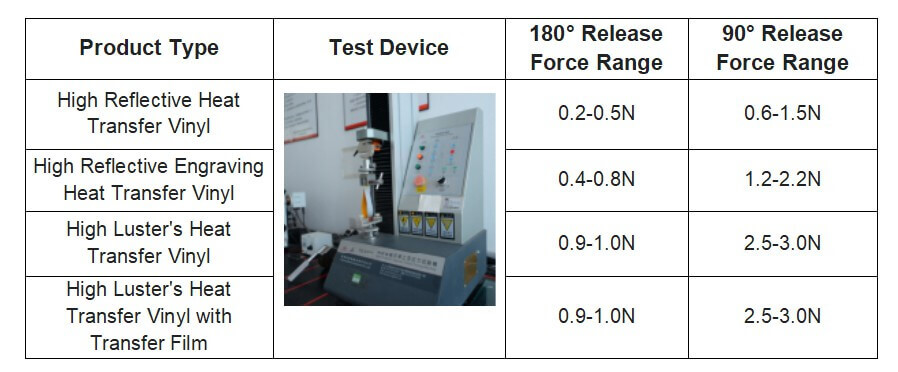

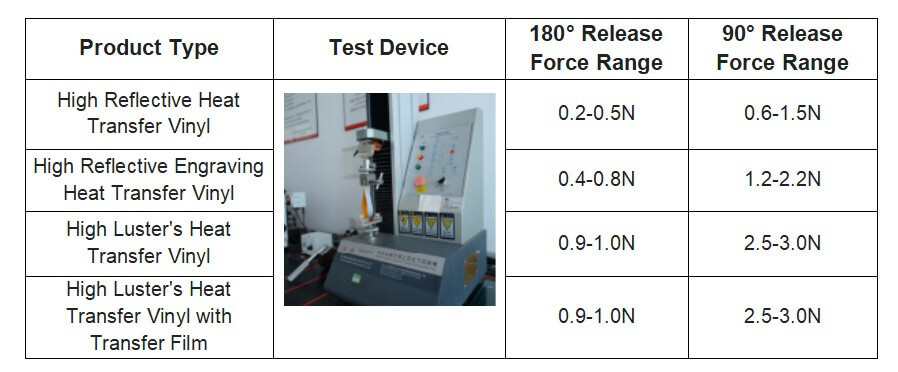

Release Force

Release force is an essential parameter to check the quality of the HTV tape, and it is also known as adhesive force.

By definition, the release force is the adhesion strength between the reflective layer and the surface protective layer. It is also a critical parameter for monitoring the application of hot pressing or cutting logos — the force releases at either 90 degrees or 180 degrees angle.

The release force of the HTV tapes can be analysed with the help of a Tensile Testing Machine. Different tapes have different release forces; especially, those that have transfer film and non-transfer film.

The release force of some of the HTV tape is listed below:

- High Iron On Reflective Tape has a release force of 0.6-1.5 N at 90 degrees and 2-0.5 N at 180 degrees angle.

- High Reflective Engraving Heat Transfer Vinyl has a release force of 1.2-2.2 N at 90 degrees and 4-0.8 N at 180 degrees angle.

- High Luster’s Heat Transfer Vinyl has a release force of 2.5-3.0 N at 90 degrees and 9-1.0 N at 180 degrees angle.

- High Luster’s Heat Transfer Vinyl with Transfer Film has a release force of 2.5-3.0 N at 90 degrees and 9-1.0 N at 180 degrees angle.

What are Common Applications for Reflective HTV?

As teased above a bit, the HTV tape is of various types, and each type has its unique application from being used on fabrics to be used on vehicles. Here is a comprehensive look at all of the HTV types and their respective applications.

- High Luster’s Heat Transfer Vinyl

The first in the list is a more diverse kind of tape as it is available in various models. You can get the High Luster’s Heat Transfer Vinyl in 6 models, namely,

- WD001

- D001M

- D001

- D001-D

- D001-GS

- D001-FT

All of the models except the D001-FT have the same application. The D001-FT model of the High Luster’s Heat Transfer Vinyl tape is primarily used on shoes and bags. The reason behind this is the scratch-resistant and wear-resistant properties of the tape.

The rest of the models of the tape are used in applications such as hot pressing on fabrics like polyester, webbing, T/C, and others. Moreover, these can also be used on safety clothing. You can cut them into logos and strips for various purposes.

To ensure that the tapes deliver their required functionality, it is necessary to use them at the prescribed temperature and pressure. For instance, the hot-pressing temperature of the High Luster’s Heat Transfer Vinyl tapes is 130-150℃, and the pressure is greater than 2kg/cm². They should be hot-pressed for 12-15 seconds.

- High Luster’s PU Heat Transfer Vinyl

The High Luster’s PU Heat Transfer Vinyl tape is available in two models, namely,

- D001-P

- D001-DP

Both of these tape models have the same application. They both can be used for hot pressing on fabrics such as PU and PVC. This is the reason it can only be scrubbed with water. Besides, it should not be soaked in water or machine washed for a long time.

Other than this, the model D001-DP is also scratch-resistant. If we talk about the processing conditions of the tapes, both of them should be hot-pressed at a temperature of 120-130℃, and the required pressure is the same as for the models of High Luster’s Heat Transfer Vinyl tape. The time for which you need to iron the tape on the fabric is 12-15 seconds.

- High Luster’s Engraving Heat Transfer Vinyl

This is a type of HTV tape that has a bit of unique functionality. It is available in only one model, D001-K, which can be used for lettering, engraving patterns, etc. After this, it can be easily pressed onto fabrics like polyester, webbing and T/C (Tetron Cotton).

Just like the other tapes, it needs to be pressed at a pressure greater than 2kg/cm² for 12-15 seconds. The safe temperature for which the tape needs to be pressed is 130-150℃.

- High Luster’s Elastic Heat Transfer Vinyl

As the name suggests, this tape has some form of elastic properties as compared to the other tapes. If you plan to buy it from YGM, we supply it in two models, namely,

- D004-7D

- D004-7P

Both of these have elastic characteristics; the D004-7D is primarily used for hot pressing onto the general elastic fabrics, whereas the D004-7P model is fit for hot pressing on elastic bands or high elastic fabrics.

The application of both these models may seem similar to you, but here is the catch! The D004-7D has a processing temperature of 130-150℃, whereas the processing temperature of the D004-7P High Luster’s Elastic Heat Transfer Vinyl is 120-130℃.

The pressure and pressing time for both of these models are >2kg/cm² and 12-15 seconds.

- High Luster’s Flame Retardant Heat Transfer Vinyl

As compared to other tapes, this tape has the unique property of being ready to be pressed onto flame retardant fabrics. It is available in four models listed below:

- D001-H

- D001-H-GS

- D001-H-GS

- DH102-12

Now, all of these models have the same operating temperature of 130-150℃, same pressure of >2kg/cm² and same processing time of 12-15 seconds.

The key difference between the models is this:

The D001-H High Luster’s Flame Retardant Heat Transfer Vinyl is suitable for pressing onto flame retardant fabrics that have average washing performance.

In contrast to this, the D001-H-GS, D001-H-GS, DH102-12 are ideal to be used on flame retardant fabrics with high washing requirements.

- Colourful Series Heat Transfer Vinyl(High Luster’s and ordinary reflective)

This is a set of HTV tapes that come in various colours. You can choose any colour based on your preference. However, you need to make sure if you need it for the intended use. The colourful Series Heat Transfer Vinyl taps are used for lettering and engraving patterns and then hot pressing onto the fabrics.

It is available in only one model, D201-X. The processing aspects of the tape are as follows:

- Temperature: 130-150℃

- Pressure: more than 2kg/cm²

- Time: 12-15 seconds

- High Iron On Reflective Tape

This variant of the HTV tape comes in two models, namely,

- D101-A

- D101

The colour of this tape is primarily grey, and both the models of this tape have similar applications. Both of these are ideal to be hot-pressed on fabrics such as polyester, webbing, and T/C (Tetron Cotton).

As far as the processing needs are concerned, both of these models will perform the best if hot pressed at 130-150℃ with a pressure of more than 2kg/cm² for 12-15 seconds.

- High Reflective Engraving Heat Transfer Vinyl

The High Reflective Engraving Heat Transfer Vinyl is the tape that offers excellent air permeability, which is the reason it can be used for lettering and engraving patterns. Moreover, it can also be hot-pressed onto various fabrics like polyester, webbings, T/C, etc.

The tape has only one model named D101-K. The processing figures of this tape are the same as those of the High Iron On Reflective Tape.

Can you apply wet reflective vinyl?

We get this question from a lot of our users. So here is the perfect answer to this!

No, it is not recommended to apply the Iron On Reflective Tape if it is wet. The reason behind this is the aluminium layer that forms a part of it.

If you apply the tape wet on the surface, the following scenarios may happen:

- The aluminium layer of the Iron On Reflective Tape is meant to prevent the airing capacity of the tape. If you apply the tape wet on the surface or on the wet surface, the airing capacity will be hampered, and the air will not escape from the surface. This will further lead to less adhesion.

- Other than this, applying the tape wet on the surface will lead to the degradation of the tape material. The reaction of water with metal will lead to corrosion of aluminium and thus damage to the tape.

Hence, whenever you need to apply the tape, the surface should always be free from any type of moisture. This is to prevent the adhesive quality of the tape.

It is important to note that wet application of the product voids the warranty. Moreover, the pH balance of the reflective tape will also be affected by wet applications.

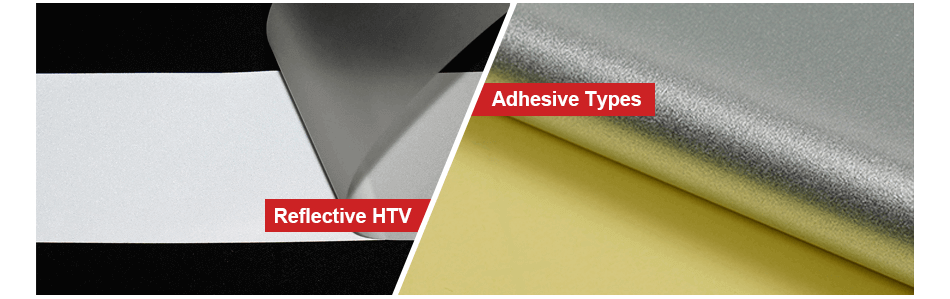

How to tell the difference between Adhesive & HTV Vinyl?

Some of you may think that the adhesive vinyl and HTV vinyl are the same. We want to inform you that there is a lot of difference between the two based on the structure and usability. Here is a brief comparison section for your reference:

Structure: Both the tapes vary a lot based on the structure. For instance, the adhesive vinyl has a paper backing that is sticky to touch when the backing of the tape is peeled off. Plus, it is available in various colours and finishes.

Unlike adhesive vinyl, the HTV vinyl has a clear plastic carrier sheet that covers the top of the vinyl. It does not feature a paper backing.

Application: The use of the adhesive vinyl is pretty simple; you just need to stick it to the surface, whereas the HTV vinyl needs to be hot-pressed onto the fabric for a permanent fix. Other specific uses of the HTV vinyl are off the charts.

How to Test the Quality of Reflective HTV?

We at YGM ensure that every product made by us has the capability to give its best. Hence, we make sure that each of our products passes the required testing phase or method. If you want to test the authenticity of the product from your end, you can follow the below-mentioned steps:

- When you get your order, check and ensure that the reflective surface of the tape is smooth and it does not have any unnecessary spots on it.

- Post this; you can tear off the protective film of the tape and verify if there are glass beads on it.

- Now, when you are done engraving the required logo or pattern on the tape, check if the extra material on the tape comes off easily or not.

- After the hot pressing process is over, it is necessary to check for wrinkles on the surface of the tape. Moreover, also check if the glass beads fall off when rubbing your hand on it.

We at YGM try that all these steps yield negative results to ensure that you get the best product.

How do you use Reflective HTV?

Well, so far, we have just studied the uses of the HTV in bits, right! But, now, in this section, we will provide you with a better overview of the uses of HTV tape.

HTV is of various types and each of which has a number of applications. Here are some of the applications of the HTV tape:

Fashion

One of the key uses of the Iron On Reflective Tape is in fashion clothing; how? Well, you can easily cut out the required graphics and logos from the tape, and hot press them on the fabrics to create your own custom dresses. However, you need to follow the temperature, pressure and time requirements of the hot pressing procedure.

These are best in making glow in dark t-shirts and tops. You can also use some of the HTV tapes like the High Luster’s PU Heat Transfer Vinyl and High Luster’s Heat Transfer Vinyl on shoes and bags. These are scratch-resistant and wear-resistant.

Safety applications

The second use of the Iron On Reflective Tape is in safety clothing such as for policemen, firemen, construction workers, security personnel, and electricians.

HTV tapes like High Luster’s Flame Retardant Elastic Heat Transfer Vinyl, High Luster’s Fluo-Yellow Warning Iron On Reflective Tape and High Luster’s Fluo-Red Warning Iron On Reflective Tape are meant to be used in road construction applications. The reflective tape on the clothing of the workers makes them visible at night.

Moreover, it can also be used by those working in professions like electrical and fire department. The tapes can be easily hot-pressed onto flame retardant as well as elastic fabrics.

How to use the HTV tape

Here is how you can use the tape on the fabric:

First off, begin with cutting the tape into the required shape like any graphics, logo, pattern or strips if it is for any special uniform. You can simply use a knife or a laser cutting machine for this.

Post this, place it on the desired fabric and hot press it at the prescribed temperature, pressure and time. Usually, the temperature of pressing is between 130-150℃, and pressure is greater than 2 kg/cm2. You need to carry on the hot pressing process for around 12-15 seconds to get the best results.

Let the tape cool, and then remove the carrier sheet from it. There is the design that you needed on your shirt.

What Should I Know Before Ordering Reflective Tape Iron On?

With so many choices of reflective HTV, anyone can feel overwhelmed while picking one. Hence, it is necessary to align your preferences beforehand. Here are some of the factors that you need to check while making your final pick among these HTV tapes.

Type of cutting

First off, you have to decide if you want to cut logos or stripes. If you are cutting logos, the blade work will be more. In contrast, if you are cutting stripes, the blade work will be less. Moreover, the type of tape and cutting method also matters.

For instance, if you are using laser cutting for cutting logos of PES and TPU, it will not cause any issue. In contrast, if you are using a plotter, it will be easier to cut PES backing than TPU as it is sticky. TPU can get trapped under the blade during cutting.

So, choose the tape that can be easily cut with the device you have.

Washing

Fabrics need washing after some time. Hence, it is necessary to choose the tape that can be washed easily and repeatedly. Though all the HTV tapes can be washed repeatedly, it is the method of washing that matters.

There are basically three types of washing methods, namely, industrial washing, machine or home washing and dry cleaning. Besides, there are some fixed standards for all of these.

For instance, ISO15797 washing is the industrial washing method that can be used for washing tapes like High Luster’s PU Heat Transfer Vinyl. On the other hand, ISO6330 is the home washing standard used for tapes that do not have high washing requirements.

You need to check the washing requirements before purchasing the tape. In case of any issue, you can always get in touch with us.

Reflectivity

Another indispensable factor that you need to keep in mind while choosing a Reflective Tape Iron On is reflectivity. If you need the HTV tape for use in safety clothing, it is best to go for those that have high reflectivity.

Most of the highly reflective HTVs have reflectivity over >400 cd/lx/m². Some of those tapes are:

- High Luster’s Heat Transfer Vinyl

- High Luster’s Engraving Heat Transfer Vinyl

- High Luster’s Industrial Wash Heat Transfer Vinyl

- High Luster’s Flame Retardant Elastic Heat Transfer Vinyl

- High Luster’s Elastic Heat Transfer Vinyl

And others! Keep the reflectivity factor along with the application of the tape in mind for making an informed choice.

Scratch-resistant and wear-resistant

One of the best applications of the HTV tape is that it can be used on bags and shoes. If you are purchasing the HTV tape from YGM for this purpose, it is necessary for you to check if it is scratch and wear-resistant.

The HTV tapes like High Luster’s PU Heat Transfer Vinyl and High Luster’s Heat Transfer Vinyl are absolutely resistant to scratches and any kind of wear. So, go for these if you want to make your bags and shoes more appealing.

Flame retardancy

This is another cool feature that can be found in some HTV tapes. The use of these tapes is in safety applications such as fire protection and electrical department. When purchasing tape for these applications, ensure that it can be easily hot-pressed onto fabrics that have flame retardancy.

The High Luster’s Flame Retardant Heat Transfer Vinyl tape will be the ideal choice if you are seeking to use it for safety clothing.

All these are some of the key factors that you need to closely analyse while making a pick for the ideal HTV tape. Apart from these, you can also check performance, elasticity, hardness, etc., for added utility.

How do you cut Reflective HTV?

To make cool graphics, it is necessary for you to cut them precisely. And when you get the heat transfer vinyl tape for the very first time, you can cut the tape in two ways. Here are both of those ways explained in detail:

Strip Cutting: If you are using the strip cutting method, it will not require much of a blade prerequisite. Moreover, there is no boundation to the type of method used for cutting. It can be cut into strips using either the plotter or the laser cutting machine. Whether the tape has a PES or a TPU backing, it can be easily cut into strips as it is much easier to operate on it.

Logo Cutting: Logos and graphics are something that does not have a symmetrical, or we should say, easy to cut shape. Hence, there is a need for special equipment to cut them. When cutting HTV tapes, you need to use professional equipment such as Silhouette Cameo 3, Cricut, or other cutting machines.

If you are using a computer cutting app, you need to open the design in the app. Scale it to the correct dimensions and then mirror the design. You need to xerox the pattern, so you’re cutting the heat transfer vinyl back. You’re going to turn it back the other direction when you add it to your shirt.

These are the two best and effective ways to cut the Iron On Reflective Tape.

What is the utility of Transfer Film in the Reflective HTV?

The transfer film is one of the most crucial elements of the Reflective Tape Iron On; why? It has some prime features that make it ideal for hot pressing as compared to ordinary protective films. Here are some benefits of the transfer film in the reflective HTV:

- The presence of the transfer film ensures that the logo does not move once it is pressed onto the fabrics. This is because the transfer film is sticky and transparent. Moreover, these characteristics of the tape also ease the process of hot pressing.

- In the case of ordinary protective films that have PE+PET, the PE material melts at high temperatures and sticks to the fabric. In contrast to this, the reflective HTV just has PET which eliminates the melting part, thus preventing cloth biting or any other damage.

- Other than these uses and benefits, the transfer film is also used by customers in various other applications.

How can I Assure the Quality of Iron On Reflective Tape?

To know that you have got the right product as ordered and most importantly if it is of good quality, you can perform some of the steps by yourself such as:

- Check if the tape has a separation between the grey vinyl and the protective layer. If yes, you need to get the product replaced.

- As it is reflective tape, it is necessary to ensure that the glass beads stay intact on the tape. You can tear off the protective layer of the tape to see if any glass beads fall.

- If you have any type of cutting machine like a plotter or a laser cutting machine, make sure that you test the tape by cutting it into logos or strips.

- As you will be required to wash the fabrics and the tape with it, it is important to check if the tape can be washed in a machine or by hand as per the ISO6330 standard.

How can I make my Iron On Reflective Tape stick better?

YGM provides you with the best in class products. However, it does not mean they cannot get damaged. If you don’t use the reflective HTV as per the provided instructions and conditions, it is inevitable that it will get damaged.

Here are some tips & tricks that you can follow to ensure that the Iron On Reflective Tape performs better:

- To make your HTV vinyl tape last longer and perform better, it is necessary to choose the fabric and the HTV tape carefully. More important than this is the processing requirements. For instance, each of the tapes has its unique processing temperature, pressure and time. Stick to these parameters while operating.

- Undertake the hot pressing process within the specified conditions. After you are done with the hot pressing, cool down the surface and remove the protection layer slowly.

- To keep the vinyl smooth on the fabric, make sure that you reduce the temperature of the press and press the pattern for 12-15 seconds.

This way, you can keep the tape in good condition for a longer time.

What can be the reasons for Heat Transfer Vinyl not Sticking properly?

If you have operated on the reflective HTV and it is not sticking, or you are doing it for the first time, there are some steps and instructions to follow. Sticking the tape to the fabric will be best if you take care of the following:

- Check for the conditions that need to be followed for sticking the tape to the fabric, such as temperature, pressure and time. Moreover, follow all the necessary directions carefully. Here is a quick overview of the parameters:

Pressure: It is necessary to apply pressure on the tape while ironing to ensure that it sticks to the fabric permanently. As the tape has a transparent surface, you will be able to see the weave on the cloth through the vinyl. If you think that the pressure applied by you is less than required, you can put on some extra weight.

Temperature: As there are 12 types of vinyl tapes, all of them have an operating temperature range. You need to keep the iron temperature within this range to get the best results.

Time: The third crucial parameter is time. If you iron the tape on the fabric for less time, it may not deliver the required functionality and may even wear off quickly. On the other hand, if you iron the tape on the fabric for long, the adhesive of the tape may get damaged on burning.

- The second reason due to which the vinyl tape might not be sticking is the fabric. Along with the tape, it is equally necessary to check the type of fabric which you are using. For instance, the TPU type HTV tape is best for spandex fibre. If you are cutting logos, the PES tape HTV is the best.

- While hot pressing the tape on the fabric, keep in mind to avoid thick seams, buttons, zips or collars. These might make your hot pressing process difficult.

- Peeling of the carrier layer of the tape at an inappropriate time may also lead to improper sticking or design damage. This is the reason some of the tapes need their carrier layer to be peeled off immediately after pressing, whereas some of them need to be cooled first.

How Well Does the HTV Hold up?

If used as per the required guidelines, the HTV tape will last for a long time. Moreover, iron-on vinyl will last longer than the t-shirt itself, provided you have chosen the right type of vinyl.

If you want the HTV tape to hold up well, turn the clothes inside out and then wash them with cold water. Also, do not scrub the fabric hard as it may damage the tape.

What are the Suitable Materials to use HTV Reflective on?

As stated a number of times in the sections above, the type of fabric plays a crucial role in the performance and processing of the HTV tape. The operating temperature range of most of the HTV tapes is between 120-150°C which means if exceeded over 150, the tape will melt.

The backing fabric of the HTV tapes is either TPU or PES. Hence, it is crucial to know which fabric will be best for which HTV tape.

The tapes that have TPU as the backing fabric are fit to be applied on PU and PVC fabrics, whereas those with PES backing can be applied on webbing, polyester cotton, nylon, etc.

Here is a head-to-head comparison of the PES and TPU backing HTV tape:

| PES | TPU |

Composition | Polyester | Thermoplastic Polyurethane |

Transparency | White translucent | Transparent, Translucent, Matte |

Elasticity | General | Very good |

Soft and comfortable | General | Very good |

Washing | Very good | General |

Dry cleaning | Very good | General |

Temperature resistance | Good high-temperature resistance | Good low-temperature resistance |

Hot pressing temperature | 140-150℃ | 130-140℃ |

So, in a nutshell, fabrics like polyester cotton, webbing, nylon, PU and PVC are fit for specific types of HTV tapes.

What is the Difference Between Reflective HTV & Reflective Tape for Sewing?

While browsing through the products made by YGM, you must have noticed that there are tapes with a few similar names like the Reflective HTV and the Reflective Tape for Sewing. Both of these tapes are different as per applications. So, don’t get confused. Here are some prime differences between the 2 tapes.

Carrier sheet: On one hand, the carrier sheet made of PET film, PE/PET composite film, or clear safety film of the Reflective Tape Iron On is peeled off after hot pressing. On the other hand, the carrier sheet of the reflective tape for sewing is peeled off during the manufacturing process.

Substrate: As far as the substrate is concerned, the reflective HTV has a substrate made of PES and TPU (hot melt adhesive film), whereas the substrate of the reflective tape for sewing is made of 100% polyester, T/C, 100% cotton, 100% aramid, and 85% polyester+15% spandex.

Application: The Reflective Tape Iron On is used for hot pressing on garments and fabrics. You can cut it into various logos with a knife and a laser plotter. You can also create custom logos from this.

In contrast, the reflective tape for sewing is used for stitching onto safety clothing. As its surface has water-repellent applications, it can also be used to create reflective umbrellas.

How do you Iron on HTV?

No, this is an interesting part as it will help you learn how you can hot press the HTV tape on the fabric. To do it successfully without error, follow the mentioned steps:

- To print a design on your shirt or any other fabric, first, off you need to create a digital version of it. You can do this by using your computer software.

- After your digital graphic is ready, it is time to cut that graphic out of the HTV tape.

- For this, you can use a plotter or a laser cutting machine. Keep the transparent layer of the carrier sheet facing downwards while cutting.

- Remove the extra vinyl left after cutting the design.

- Place the created vinyl graphic or print on the fabric and hot press it at the required conditions such as 120°C-140°C (temperature), 2-3kg/cm² (Pressure) for 12-15 seconds. Make sure you heat press the fabric while keeping the transparent layer of the carrier sheet facing upwards.

- If the iron you are using to press the tape is a home iron, apply extra pressure on it for best results.

- Leave the pressed tape to cool. When cooled after some time, peel off the carrier layer. If you see any uncertainties in the design like lifting off, heat press it again.

What Problems Do Consumers Usually Face When Using Reflective HTV and What are the Reasons?

Well, there are many issues brought to our notice by our customers. If you also have any of these issues, do get in touch with us or read the helpful methods provided below!

- Layer issues

In this, there can be two scenarios,

|

The reflective HTV may not be firm on the fabric |

The adhesive may melt along with the glue layer |

|

The methods to avoid this are: ● The combination of pressure, time and temperature need to be right. ● If the fabric is treated properly with oil and water resistance, it will not pose any issue. ● Keep the usage time and storage conditions in mind like Temperature: 15-30℃, humidity: <60%, shelf life: 1 year. |

The method to avoid this is to keep the temperature and pressure of the overall process controlled and within limits. |

- Falling Glass Beads

If you experience glass beads falling, then the glue curling time is not up, or the strength of the glass beads is not up to mark.

- After cutting the logo, the extra vinyl tape stuck to the logo, & it could not be peeled off perfectly.

The sole reason for this can be the power of the logo cutting machine. It might not be set at the required level.

- After finishing the hot pressing, the reflecting portion was removed when the transfer film was torn off.

Here are the potential reasons for this issue:

- The glass beads of the tape are embedded too deep.

- The force with which the transfer film is peeled is more than required.

- The duration of glue curing is not enough.

Do check for these issues and report to us for solutions!

At what temperature should the Heat Press be Set for HTV?

Well, this is the question that most of you must be looking up to. As the reflective HTVs have two types of backing materials, namely, PES and TPU, the temperature at which they need to be pressed is also different.

- PES

Temperature: 140-150℃

Pressure: 3-5kgf

Time: 12-15s

- TPU

Temperature: 130-140℃

Pressure: 2-4kgf

Time: 12-15s

What types of Iron On Reflective Tape does YGM offer?

YGM offers overall 12 types of Iron On Reflective Tape. These can be collectively classified into four series named as:

- Silver Iron On Reflective Tape

- Grey Iron On Reflective Tape

- Colourful Iron On Reflective Tape

- Rainbow Iron On Reflective Tape

Does YGM Manufacture Iron On Reflective Tape? Can I order reflective HTV from YGM?

Yes, we at YGM are one of the reputed manufacturers of Iron On Reflective Tape. We cater to our customer all around the globe, which is the reason we have an awesome track record of around 16 years.

What is the size of YGM Iron On Reflective Tape?

Iron On Reflective Tape has numerous applications. This is the reason it is necessary to know the sizes of the tapes available, as it may vary based on their use.

As it is used to cut out logos and graphics, you need to get the one that has more width. On the other hand, the tape is also useful for safety applications where it is used in the form of strips, so the size will vary here too.

YGM provides you with reflective HTV in three width choices such as 5cm, 50cm and 1m. The one with the maximum width can be used for graphics creation, and the one with less width can be used on safety clothing.

If you have any specific requirements, you can let us know. We can customize the size as per your need.

Can I order a custom-size of Iron On Reflective Tape? Are the specifications customizable too?

Yes, unlike other manufacturers, YGM caters to its customer’s unique needs. You can let us know your custom needs, and we will make the tape as per the requirements.

Yes, you can get the specifications of the tape customized too. We can make adjustments to the size, pattern and even aperture of the reflective HTV.

How long does YGM take to produce & deliver my order of Iron On Reflective Tape?

YGM is not just popular because of its product quality. We make sure that we deliver the best products within a minimum time to you. Hence, when you order a product from us, we give you the minimum lead time.

As we deliver products all around the globe, you can expect your reflective HTV to reach you within 25-30 days.

Does YGM offer free samples for Iron On Reflective Tape?

Yes, we at YGM offer free samples of our products to our customers. However, you need to note that you have to pay freight charges. Once you have confirmed your order with us, we will automatically deduct the freight from your order.

Are YGM products always available and in stock? Do I need to pre-order & await new stock for months after ordering?

Well, the products that are mostly ordered by our clients are always in stock. These are some of the regular products.

On the other hand, if you are ordering custom products from YGM, we will produce them as per your order. However, you need to assure that you order at the right time so that you can get them within 25-30 days. You won’t have to wait for months to get the order delivered.

What are the various certification standards when it comes to reflective HTV? How are they updated?

To make our products safe for the users while maintaining their quality, we ensure that they are certified with all the necessary certifications. Here are some of them:

Oeko-Tex Standard 100

This is a certification that our Reflective Tape Iron On has for the safety of humans and the ecosystem when purchasing clothes, fabrics, & leather during the production stages or ready-made items.

EN ISO 20471

An international standard, EN ISO 20471, requires that the reflective material should be placed on only stipulated areas so as to avoid blind angles and ensure high visibility from all sides. It is divided into three categories,

- Class 1 (reflectivity: 0.10 m2)

- Class 2 (0.13 m2)

- Class 3 (0.20 m2)

Apart from making our products completely certified, we also keep a check on updating the certifications with time.

How do I ensure the Iron On Reflective Tape remains at its best quality?

To keep your Iron On Reflective Stripes at its best quality, it is necessary to keep an eye on the usage of it. For instance, always hot press the Iron On Reflective Stripes at the required temperature, pressure and for the required duration.

Moreover, pay close attention to how you wash it. For instance, you need to follow the required washing standards. Don’t soak it in water for long and never machine for a long time.

What packaging options do you offer at YGM for Iron On Reflective Tape?

To make sure that the product reaches our customers in pristine condition, we pack it in the safest way. The Reflective Tape Iron On is packed in the following way:

Obverse show > Air Bubble Film > Internal packing > Outer packing

What is the net production capacity of YGM for Iron On Reflective Tape?

Well, not to boast about, but YGM produces close to 5 million square meters of Iron On Reflective Tape in a month. Thus, making it one of the largest manufacturers in the world.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang