- info@cnygm.com

- +(0)86-576-88122360

Your Reliable Reflective Transfer Supplier

Multiple Types | Customized Stripes & Logos

- Reflective materials are essential in safety wear. However, these days, the usage of reflective fabric is no longer limited to safety wear. In fact, it now has many applications, which increased its demand significantly. You can now use reflective fabric for fashion, interior designing, upholstery, and accessories.

- Considering the reflective fabrics’ numerous uses, many companies now manufacture easy to use reflective fabrics. One among these is the reflective transfer. This reflective transfer material is heat-sensitive, making it easy to hot press it on whatever surface or fabric you require.

- This amazing reflective transfer material comes in different colors and can be customized as required too. Along with this, the reflective transfer offers essential features such as excellent washability, flame retardancy, and, most importantly, amazing reflectivity. We will be talking elaborately about reflective transfer today – read ahead to find out more details.

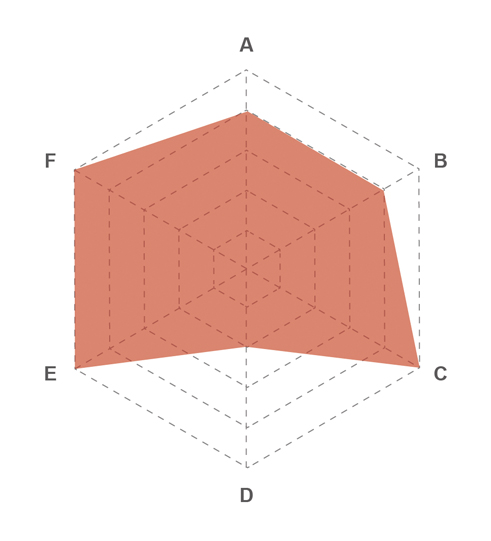

Reflective Transfer Feature

One of the main questions our clients have is this – what exactly are the features of reflective transfer? What exactly makes it different? To answer this, we have listed down the essential features of transfer fabric. Whenever you decide to purchase any iron-on fabric, do make sure you look for these features in it. Let’s get started:

A:Reflectivity

This is the first and foremost factor that cannot be compromised in any case. When you purchase reflective fabrics, you have to make sure they meet the requirement of the purpose you will be using them for. This is why you need to look for the reflective quotient of any reflective transfer you decide to purchase.

Reflective transfer is categorized into three categories, on the basis of the color and reflectivity they offer. Typically, the silver reflective transfer displays a reflectivity of 300-400cd/lx/m², whereas the grey counterparts offer a reflectivity quotient of 200-300cd/lx/m². Highly reflective colors render a reflectivity spanning from 60-80cd/lx/m² and the rainbow-colored reflective transfer reveals 60-80cd/lx/m². Ordinary colors come with the least reflectivity, and it spans from 10-20cd/lx/m² when it comes to these simple, yet highly effective HTVs.

C:Washability

Usage of HTV on industrial or safety gear makes it prone to dust, dirt, and other elements, which may hamper the reflectivity quotient over time. This is why you need to ensure that the HTV you invest in has high washability.

Every product at YGM is washable and you have three options using which you can wash the HTV. You can choose to give it an industrial wash, or even opt to wash the fabric at home. The third option was dry cleaning. You can pick a cleaning option depending upon the type of fabric you chose, your necessity, and your preference. The best part about HTV is that it has a washability of up to 50 cycles.

E:Customizability

Like other reflective fabrics, this iron-on reflective material too, is extremely customizable. If you wish to add the logo of your brand to the reflective fabric, you can do that easily! Secondly, the reflective fabric is extremely flexible and can be cut as required. You can use the laser cutting method or also choose to cut it into stripes according to your requirements. In any way, the reflective transfer is super customers bale, making it easy to use and well-suited for a range of creative purposes.

B:Color

The amazing part about these reflective transfer materials is that they can be used for a wide range of purposes. The fact that they are available in different colors further enhances the applicability of HTV. So whether you need the HTV for industrial, creative, or fashion purposes, the diverse range of colors suffice it all.

When choosing the colors, do keep in mind that the reflectivity varies depending on the color of reflective transfer you choose. The highest reflecting colors are silver, yellow-silver-yellow, red-silver-red, and lastly, the grey color. The colorful reflective transfer products offer the least reflectivity and they are well suited for creative purposes only. On the other hand, for safety and industry usage, it is best to opt for HTV with high reflectivity.

D:Flame retardancy

This feature is extremely critical, especially if you are picking the HTV fabric for your safety or industrial usage. These are high-risk areas and prone to different types of accidents, including fire. Considering these risks, you need to pick a fabric that is fire resistant and offers high flame retardancy.

Do keep in mind that not every fabric is flame retardant – only a few color combinations such as the yellow-silver-yellow or red-silver-red. The other colors are not flame retardant, so pick your material carefully.

F:Applicability

You can use the reflective transfer on basically anything and everything. Apart from safety and industrial uses, the HTV is also used rampantly in the fashion industry. Wish to glam up your T-shirts, caps, bags, and accessories? Simply add on the HTV to these fabrics and materials and watch how they glow!

You can easily cut the heat transfer vinyl with the help of a laser cutting machine or even a knife to give it the desired shape. The material is very flexible and can be easily cut into small, thin pieces too.

Why choose YGM Reflective Transfer?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Reflective Transfer Category

We will begin with talking about the range of reflective transfer products we have to offer:

High Luster’s Reflective Transfer

This reflective transfer material has a silver color and comes with PES/TPU based backing fabric. It offers a reflectivity of more than 400 CPL, making it suitable for diverse applications. You can comfortably use the PES variant on woven and cotton fabric, whereas the TPU is perfect for hot pressing onto PU or PVC-based fabrics.

At hot pressing temperature, spanning from 125-130°C, the pressing time required is only 8-15 seconds. So all you have to do is make sure you are applying a pressure of 2-3kg/cm2, and your reflective transfer will bind onto the surface in no time!

High Luster’s Engraving Reflective Transfer

With a reflectivity quotient of more than 400 CPL, this silver-colored reflective transfer material features a PES backing fabric. Its good air permeability makes it suitable for lettering and hot pressing on woven, cotton, and other fabrics.

Just like the High Luster’s Reflective Transfer, this fabric also has a hot pressing temperature of 125-130°C, along with a hot pressing pressure of 2-3kg/ cm2. Maintain the required temperature and the pressing pressure, and in less than 15 seconds you will be done with your job!

High Luster’s Industrial Wash Reflective Transfer

Due to its high-washing performance, this heat-sensitive reflective fabric is perfect for industrial use. It works well with PU as well as PVC-based fabrics and features a backing fabric of TPU. The hot pressing temperature of this product stands at 110-135°C, which is slightly lesser than the previous products.

The time taken to attach this on surfaces and other materials is the same, and you would require around 8-15 seconds for the same. Do ensure to maintain a heat pressure of 2-3kg/ cm2 for quicker results.

High Luster’s Flame Retardant Elastic Reflective Transfer

With an exceptional flame retardancy level, this reflective transfer is perfect for usage in high-risk safety gear. It comes in a silver color and features a backing fabric of TPU. Along with excellent flame retardancy, the reflective transfer is also super-elastic. As a result, this fabric works well with elastic and flame retardant fabrics.

The vinyl fabric offers a pressing temperature of 110-135°C as well as pressing pressure of 2-3kg/cm2. If you maintain both these factors, your job of fixing the reflective transfer on any desired material will be done in 8-15 seconds.

High Luster’s Elastic Reflective Transfer

This reflective transfer is backed by TPU and offers a reflectivity quotient of approximately 400 CPL. It comes in one color (silver) and boasts exceptional elasticity. If you are looking for a good quality, elastic reflective fabric, this one would fit the bill perfectly. It is suitable for hot pressing onto PU or PVC fabrics as well as a variety of elastic woven tape.

To affix this reflective transfer on materials, you need to maintain a temperature of 110-135°C as well as pressing pressure of 2-3kg/cm2. The time taken to fix this tape on any other material would vary from 8 to 15 seconds.

High Luster’s Printable Reflective Transfer

This reflective transfer offers a reflective quotient of more than 400 CPL. Silver in color, this material is well suited for a whole range of purposes, industrial and otherwise. It is particularly very useful for direct surface printing as well as for lettering and hot pressing on woven, cotton, and other fabrics.

It features a PES backing fabric. The pressing temperature of this reflective transfer material is higher as compared to the previous products and stands at 130-140°C, whereas the pressing time of 8-15 seconds and the pressing pressure of 2-3kg/cm2 stays the same.

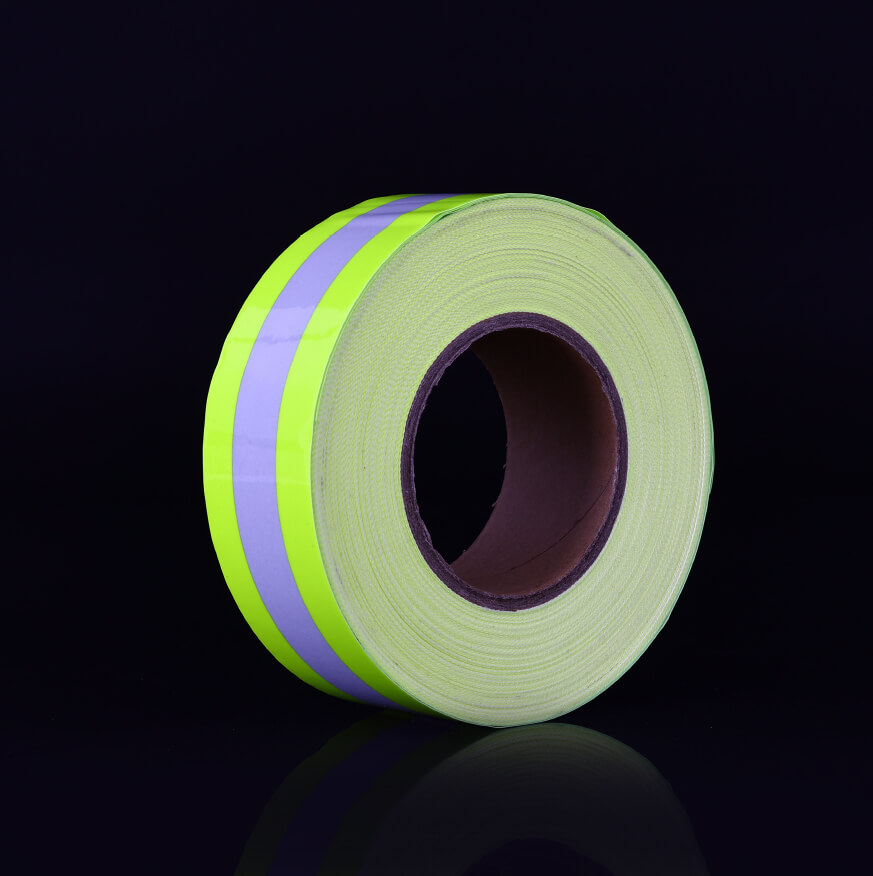

High-Luster’s Fluo-Yellow Warning Reflective Transfer

This product offers a lower reflectivity quotient of around 300 CPL and comes in an amazing color combination of yellow-silver-yellow. With a PES backing fabric, this HTV requires a pressing temperature of 130-140°C. With the right amount of pressing pressure (2-3kg/cm2 ), you can affix this reflective transfer on any fabric or surface in less than 15 seconds.

High flame retardancy and heat resistance are the unique features of this product. Thanks to these tough features, the Fluo-Yellow reflective transfer is suitable in fields of fire protection as well as in the electrical industry. This material is perfect for hot pressing on cotton, woven, and a range of other fabrics too.

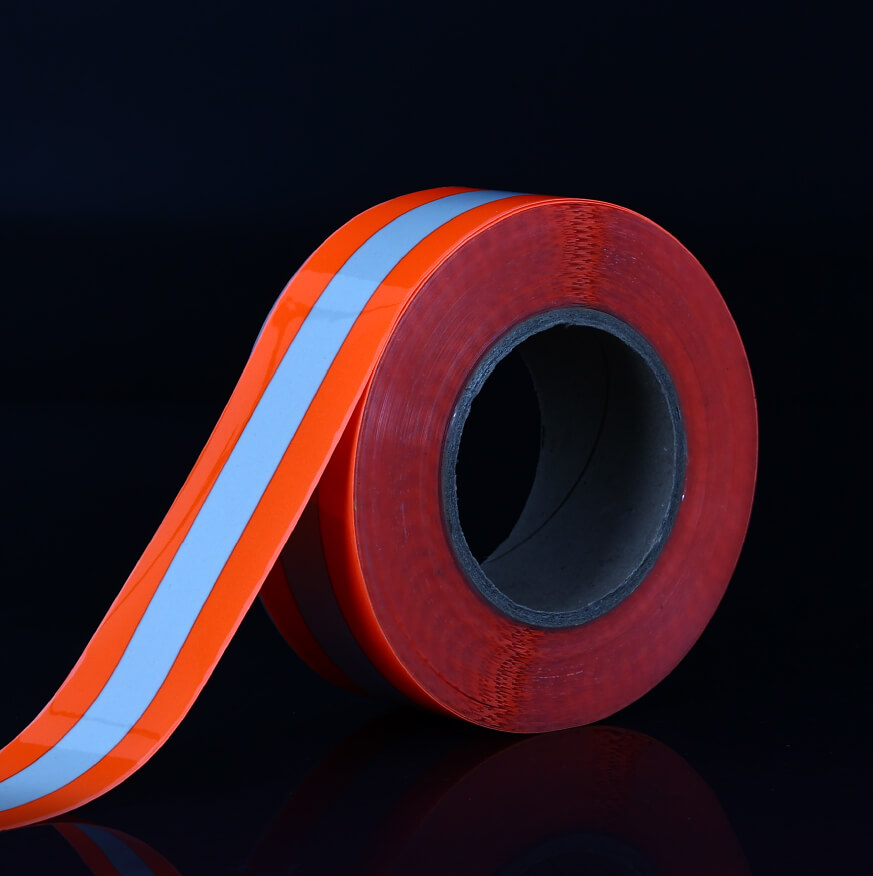

High Luster’s Fluo-Red Warning Reflective Transfer

With properties similar to its yellow counterpart, the Fluo-Red reflective transfer is also popularly used in different types of industries. It also has a backing fabric of PES but comes in the red-silver-red combination. It has an exceptionally high heat resistance level as well as a flame retardancy quotient. This makes it perfect for industrial applications, especially in high-risk fields of work. The material, its texture, and color make it perfect for hot pressing on woven, cotton as well as other fabrics too.

The reflectivity quotient of this fabric stays at 300 CPL, and it features a relatively high pressing temperature of 130-140°C, a pressing pressure of 2-3kg/cm2, and a pressing time spanning from 8-15 seconds.

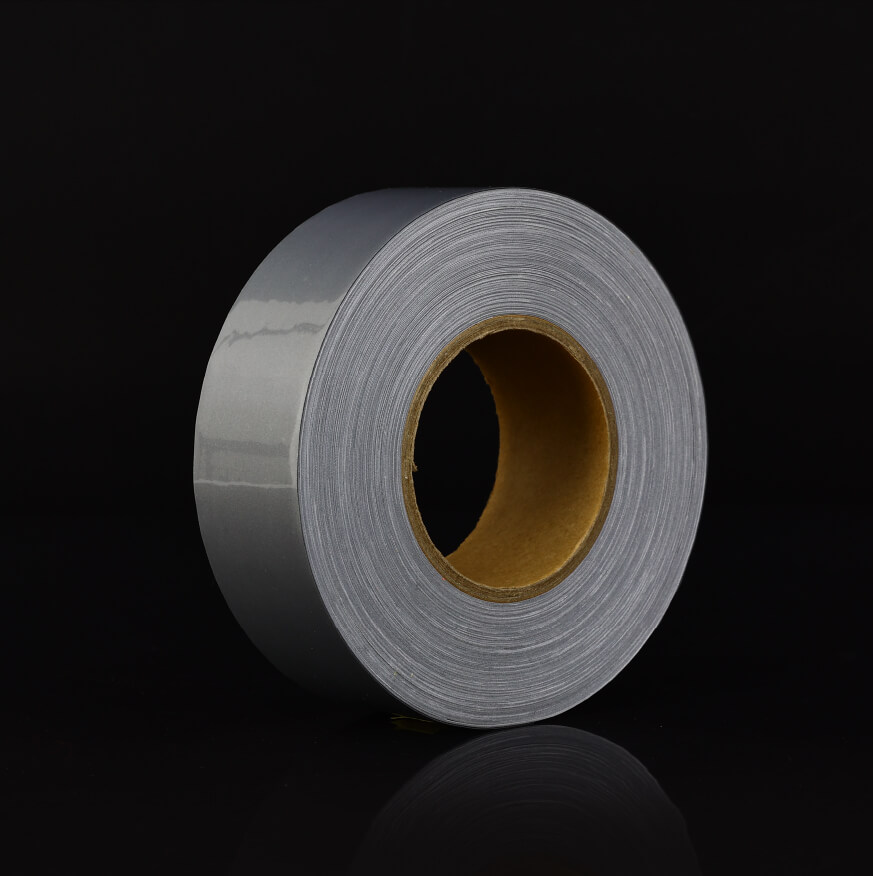

High reflective Transfer

Looking for a product that offers high reflectivity and yet comes well within your budget? Simply opt for the High reflective transfer we manufacture here, at YGM. This product comes in a grey color, so if the rest of the colorful products do not meet your requirement, this one will.

It has properties similar to the other products, with a heat pressing temperature of 120-130°C and a pressing time ranging from 8 to 15 seconds. All you have to do is ensure to maintain a pressing pressure of 2-3kg/cm2 to get the desired results.

High Reflective Engraving Reflective Transfer

This reflective transfer material features exceptional air permeability and is well-suited for lettering and hot pressing on woven, cotton as well as a range of other fabrics. It features a backing fabric of PES and requires a hot press temperature of 125-135°C. If you maintain a steady pressing pressure of 2-3kg/cm2, you would be able to easily fix this HTV on any fabric or material of your choice in less than 15 seconds.

Color Reflective Transfer

As compared to the other products, this material has the lowest reflectivity rate of around 15 CPL. The best part about this reflective transfer is that it is available in many colors (other than the standard grey, silver, and fluorescent) – and this feature makes the color reflective transfer well-suited for a range of industries as well as creative purposes. It can be easily hot-pressed on woven, cotton, and other materials at a pressing temperature of 130-150°C.

Maintaining a pressing pressure of 3-5kg/cm2 is essential if you wish to get the work done in anything between 10 to 15 seconds. The PES-backed HTV is super quick to affix and goes well with all types of materials.

Rainbow Reflective Transfer

If you are looking for iron-on reflective material for creative products, this product from YGM is the best choice. It comes in rainbow colors and features a backing fiber of PES. The pressing temperature for this product ranges from 140-150°C, and it requires a pressing pressure of 3-5kg/cm2.

If all the factors are maintained, you can easily affix this colorful, rainbow HTV on any given material within 20 seconds. Particularly, it is well suited for hot pressing onto fabric such as woven and cotton. This does not mean you cannot experiment with other fabrics – you can easily use this HTV on a range of fabric types as well as surfaces.

Reflective Transfer:The Complete Buying Guide

In this section, we will be answering anything and everything you need to know about reflective transfer, its features, advantages as well as uses. Read on to find out more about reflective transfer:

Table of Contents

What is reflective transfer?

Commonly known as reflective transfer, this fabric is a specialized vinyl polymer that is used on different fabrics, materials, and surfaces to create highlighted patterns on them. The HTV comes in a roll or sheet package. It also features an adhesive backrest that can be trimmed, weeded, and even placed on a substrate for heat application. Reflective transfer is manufactured in single colors and it also comes in off-beat rainbow-colored varieties.

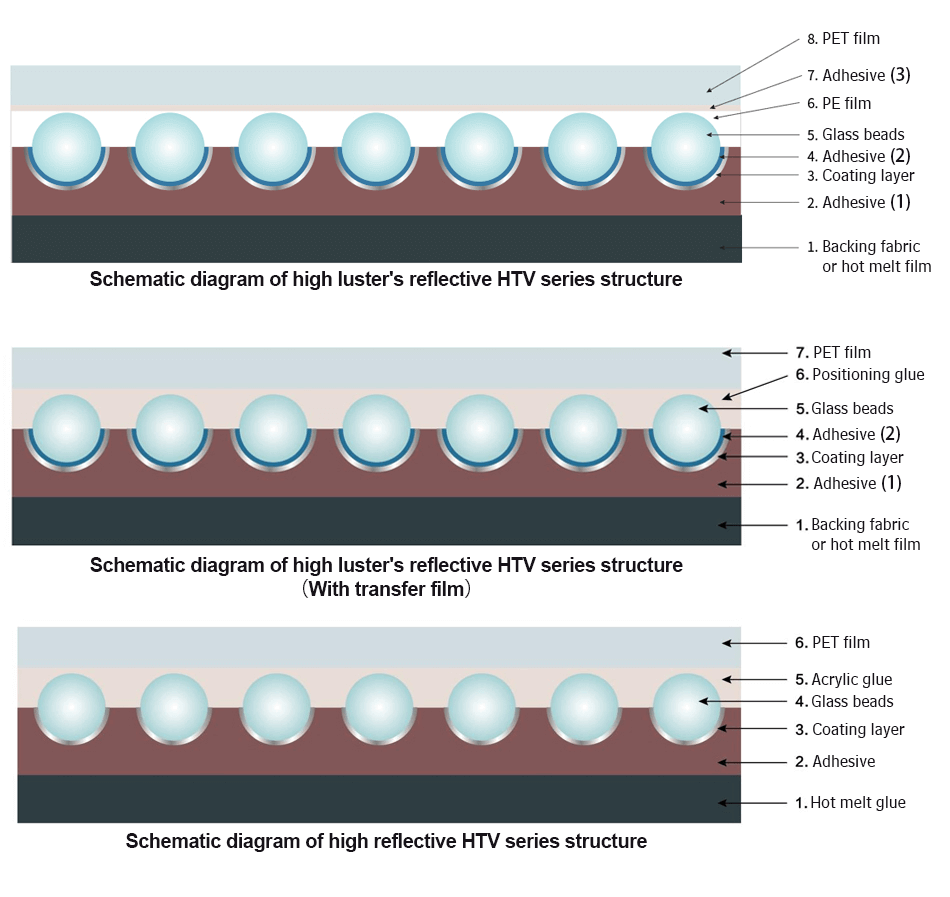

Let’s understand the structure of the reflective transfer. The very first layer features the backing fabric, which is also known as the hot melt film. Then comes the adhesive upon which the coating layer is placed, Further, you again have an adhesive layer, upon which glass beads are placed. On this, you have the PE film, another layer of adhesive, and finally, the PET film.

Why do you need reflective transfer?

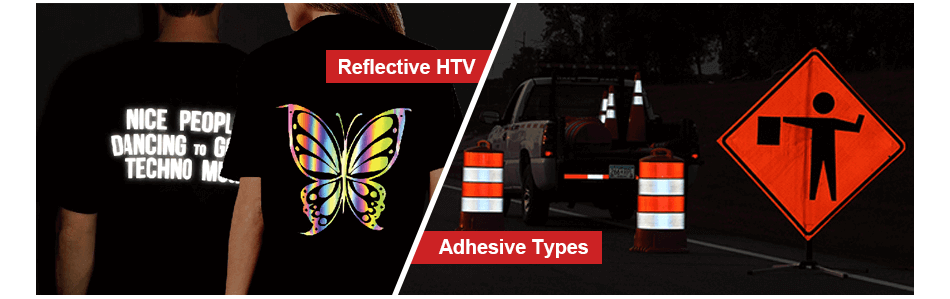

Reflective material products play a critical role in road traffic as well as outdoor safety. These days, the usage of reflective transfer is no longer restricted only to standard purposes – it is also being widely used in the fashion industry to jazz up garments as well as accessories. This is also why, nowadays, you have a whole range of reflective products – right from caps, gloves, vests, jackets, hats, and even school uniforms.

The amazing part about reflective transfer is that it is flexible and can be cut into different shapes, sizes, and designs easily. The material is a beautiful combination of safety, beauty, and fashion, which is why it is widely used now.

What are the benefits of reflective transfer?

Following are the advantages of reflective transfer which make it one of the most popular reflective products:

- Non-Destructive

This non-destructive smooth product does not cause damage to the function of the carrier material during the process of application. You can easily hot-press the reflective vinyl onto waterproof fabric, without worrying about any damages to the underlying fabric. Once affixed on any fabric, the reflective transfer does not affect the performance of the fabric either.

- Diversity of Processing

Cutting this iron-on material is super easy and hassle-free. With the help of a laser cutting machine, a knife, or even a pair of scissors, you can easily cut the fabric into different shapes, sizes and designs. This allows you to experiment and use the fabric to cut out patterns, logos, and brand names too.

- More Dynamic

This dynamic reflective transfer material is preferred by top clothing brands – thanks to the ease of usage it offers. Sports brands too, heavily rely on reflective transfer to add the glam factor to their sports apparel range.

- Flatness

The flexibility offered by reflective transfer is unmatchable. Even after you hot press the fabric on any material of your choice, it gives a smooth, compliant, and aesthetic finish. This makes the reflective transfer and the underlying material appear like one whole fabric.

What are common applications for reflective transfer?

There are various reflective transfer products and each is well-suited for different uses. You can use the iron-on material on polyester, webbing, T/C as well as other fabrics. You can also use it on shoes and bags because the material itself is durable, scratch-resistant, and wear-resistant too. Some products can also be hot-pressed on PU and PVC fabrics and these can be only scrubbed with water, not giving you the alternative to washing it using the machine.

Further, you also have products that work best for lettering, engraving patterns, or simply be for hot pressing on fabrics such as polyester, webbing, and T/C. Certain products are well suited for flame retardant fabrics, which typically come with high washing requirements. Likewise, you also have a range of products to cater to the requirements of elastic bands or high elastic fabrics.

Can you apply wet reflective transfer?

No, you cannot. Rather, you should never opt for applying wet reflective transfer. reflective transfer has an aluminum layer that prevents air permeability – this means that when you apply heat to such a material, there is no way out for the moisture that will be generated once the heat is applied.

There are times when you would have to choose to apply wet reflective vinyl fabric, but in such occasional cases too, you need to make every possible attempt to remove as much moisture as you can with the help of a squeegee. Here, you need to use wet solutions to affix the product but do keep in mind that wet solutions overthrow the pH balance of reflective transfer. This compromises the quality of the product, greatly affecting its adhesive quality.

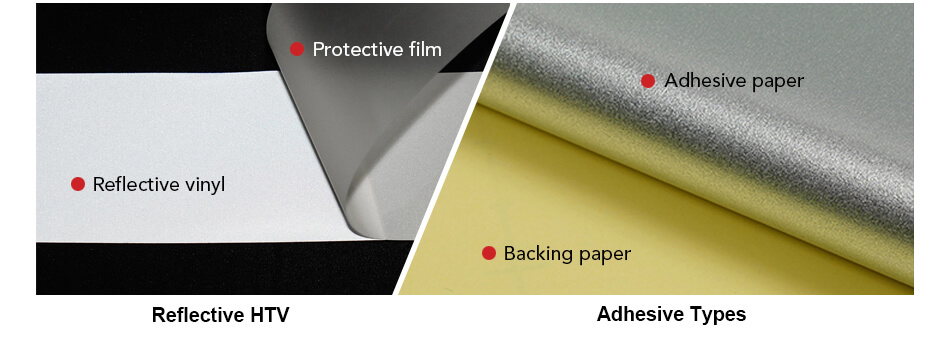

What is the difference between Adhesive and reflective transfer?

There are two main differences – firstly, the backing of both the varieties is different. Although they come in a variety of colors, the adhesive types of vinyl have the same paper backing and have a sticky base when the paper is peeled off. Likewise, HTV does not have a paper backing – instead, it comes with a clear plastic carrier sheet that covers the top of the vinyl.

Secondly, you can use the adhesive vinyl directly – it has an adhesive backing and applies mechanism, whereas, in the reflective transfer you mandatorily need heat to attach the HTV to the fabric.

How to Test the Quality of reflective transfer?

Checking the quality of the product you buy is very important. At YGM, we ensure all our products are of top-notch, industrial standard quality. Despite this, we encourage our customers to check the quality of the product before placing a bulk order. We have listed down a couple of things you need to remember when it comes to checking the quality of reflective transfer:

- Check if the reflective surface is smooth and spotless.

- Peel off the protective film and closely look into the surface revealed – here you have to look for the glass beads.

- After you are done engraving the logo, check if the extra unwanted material from the pattern comes off easily.

- Once you affix the fabric on the material of choice with a hot press, check if the former and latter fabrics are both intact. If the surface is wrinkled, the reflective fabric is not up to the mark.

- Lastly, rub the surface of the reflective transfer and check if the glass beads fall off.

Do make sure you check the quality of the reflective transfer thoroughly before you actually place your bulk order.

How do you use reflective transfer?

Reflective transfer is a beautiful amalgamation of safety and fashion and this versatile material can be easily used in a wide variety of applications. Reflective transfer shines in the dark, which makes it essential in safety fabric. Right from policemen to firemen and security personnel, everyone has uniforms that feature reflective transfer. This helps vehicles and well other humans to distinguish these personnel in the dark.

The usage of reflective transfer is no longer limited to safety wear – it is now also used in the fashion industry to glamourize clothes and give them a unique, out-of-the-box look. You can easily find reflective transfer on clothes, shoes, bags, belts as well as a whole range of accessories.

The amazing aspect about the reflective transfer is that it is super easy to use. All you have to do is follow some simple steps. First, cut the fabric as per your requirement into thin strips, patterns, designs or logos. Once you finish the cut, weed out the excess unwanted material from the reflective transfer and then proceed to the next steps.

You can then iron on these customized reflective transfer strips and hot press them onto whichever fabric, material, or surface you wish to. Just make sure you follow the instructions and maintain the required pressing temperature, pressure, and time. Set your iron on the ‘Cotton’ ironing mode and hold it down on the fabric for 15 to 20 seconds. Ensure you cover the entire design. Once the material has cooled down and the HTV has settled on it, you can then move to peel off the protective film off the surface.

Once you are done with all these steps, your reflective design is now ready to wear and shine!

What should I know before ordering reflective transfer?

If you are a safety wear manufacturer, or for that matter, any apparel manufacturer, you would definitely require reflective transfer in bulk quantities. But before you place your huge order, it is always advisable to understand your requirements and then proceed to select a material that fits in well.

There are many important factors you need to consider – firstly, the ease of usage. You surely don’t want to end up with an HTV that is difficult to cut or use. You need to look for a reflective transfer that is flexible, easy to manage as well as an affix. Next, the equipment you will be using to cut the reflective transfer comes into the picture. If you are going to use a laser cutting machine for creating your designs, choose the reflective transfer that comes with a PES or TPU backing. If you are opting for the plotter, remember it is easier to work with PES backing, as the TPU version is way sticky and may be inconvenient to work with.

Further, you need to have a look at critical aspects such as the reflectivity of the fabric, its efficiency, washability as well as its fire resistance. Each of these is a crucial aspect that has to be considered before you finally zero into the type of material that you want to buy. With the wide range of products we have, you are bound to be left spoilt for choice. At such times, don’t hesitate to seek our help – based on your requirements, we will help you pick the perfect reflective material for you.

How do you cut reflective transfer?

Depending on which pattern you wish to cut, you can choose different cutting equipment. If you require simple strips, simply use either a laser machine or a plotter – both work just as well, as there’s nothing intricate about strip cutting.

However, if you are planning to make designs, logos, and patterns, the approach changes. There are many elements and detailing that go into making a pattern, which is why you need to use professional equipment such as Cricut, Silhouette 3, or other reliable cutting machines. All you need to do is open the design in your computer app, ensure the dimensions are right, and then mirror the design. Make sure you are cutting the right side so that the perfect pattern is printed on your t-shirt.

What is the use of the Transfer Film in reflective transfer?

The transfer film is the topmost layer in the reflective transfer design. It helps prevent logo movement, as it is sticky and transparent. This makes the hot pressing a lot more comfortable and convenient. The transfer film also helps prevent the reflective transfer from biting into the cloth. Any ordinary protective film is made of PET and PE would instantly melt at a higher temperature and sear into the underlying fabric.

However, this is not the case with transfer film – it is made of PET only. PET is resistant to high temperatures and does not melt when exposed to extreme heat. Apart from technical reasons, the only other reason why every reflective transfer has a transfer film is that customers need it. Some customers require the transfer film as they need it for other usages.

How can I ensure the quality of reflective transfer?

The first and foremost thing you need to do is check for the separation between the protective film and the grey vinyl. Next, check whether the glass beads stay intact when you peel off the protective film. If they fall off, the reflective transfer is not of good quality. Further, you can also test the material by cutting it into a logo, design, or strip as required. Lastly, put it through a washing test (as per the instructions mentioned in the manual) to check its washability. These four factors should be enough to help you determine the quality of your reflective transfer.

How Can I make my reflective transfer stick better?

Before you begin anything else, give the instruction manual a thorough read. The manual would describe the important aspects such as pressing temperature, pressure as well as time clearly. Keep in mind these three critical aspects as you begin working with the reflective transfer.

Next, use a well-heated iron to hot press the vinyl onto the cloth. Make sure you press across the design evenly, so that you don’t have any uneven edges. Once it cools down, only then peel away the protective layer. Lastly, shift the heat down a little, and then press the pattern for 12 to 15 seconds to ensure the vinyl is completely smooth.

Why is my reflective transfer not sticking?

The only reason this isn’t working out is that you aren’t doing it right. That’s precisely why we ask all our clients to read the instruction manual thoroughly before they begin working with the vinyl. One of the reasons why your reflective transfer is not sticking well to the fabric is that you aren’t maintaining the required pressing temperature and pressure. Also, if you don’t apply the required pressure for the time specified, your reflective transfer will not stick to the fabric in any case.

Make sure you iron just as much as required – if you iron too much, the adhesive will burn off the HTV. Test the temperature before you start working on the final product, which will help you get a better idea. Similarly, when it comes to pressure, make sure it is uniform and evenly distributed – only then will your reflective transfer blend into the fabric seamlessly.

Likewise, different reflective transfers have different requirements – some need to be cooled down before taking off the plastic carrier sheet, while for other HTV varieties, it has to be taken off immediately. Do remember, thick seams, zips, collars, and buttons are problematic areas where affixing the reflective transfer may not be possible.

What are the suitable materials to use reflective transfer on?

This iron-on material comes with two types of backing fabric – PES (polyester) or TPU (Thermoplastic polyurethane). Depending upon your requirements, you can pick one that works well for you. TPU has strong elasticity and is primarily applied to elastic fabrics such as PU and PVC. In contrast, PES is mainly used for hot pressing on polyester cotton, nylon, webbing, and other such fabrics.

PES has a higher temperature resistance than TPU, but in other aspects such as elasticity, flexibility, TPU wins brownie points over PES.

| PES | TPU |

Composition | polyester | thermoplastic polyurethane |

Transparency | white translucent | transparent, translucent, matte |

Elasticity | general | very good |

Soft and comfortable | general | very good |

Washing | very good | general |

Dry cleaning | very good | general |

Temperature resistance | good high temperature resistance | good low temperature resistance |

Hot pressing temperature | 140-150℃ | 130-140℃ |

What is the difference between reflective transfer and reflective sewing tape?

We have explained in detail how reflective transfer works – all you have to do is cut out the required dimensions and hot press it onto the desired fabric. On the other hand, reflective sewing tape has to be sewed onto the desired fabric to ensure it attaches well. In the latter, there is no peeling off the topmost plastic layer involved.

Reflective transfer offers a lot more flexibility as compared to the reflective sewing tape, as it can be cut into different shapes and sizes. It also has a unique, water-repellant feature, which makes it suitable for anything and everything!

How do you iron on reflective transfer?

Firstly, build a template on your computer. Use a knife or laser plotter to cut the vinyl. At this step, make sure the transparent layer of the carrier sheet is facing downward. Take off the excess unwanted parts of the vinyl, leaving your design on the carrier layer.

Place the vinyl design on the cloth, ensuring the transparent layer of the carrier sheet is facing upwards this time. Then, depending upon the type of vinyl, set the temperature, pressure, and time required. Hot press the vinyl evenly, to make sure it blends seamlessly onto the fabric. After 30 seconds, when the vinyl cools off, peel off the carrier layer. While doing this, if you notice any part of the design coming off, place the iron on it again, and you will be good to go.

What temperature should the heat press be set on for reflective transfer?

The temperature for the hot press varies for different reflective transfer products. For PES-based fabrics, you need to maintain a temperature of 140-150°C, whereas for the TPU backed reflective transfers, the temperature is 130-140°C. However, the pressing time required for both varieties is the same, and it takes only 12 to 15 seconds to affix a reflective transfer on any given fabric – provided you follow all the criteria right.

Backing Fabric | Hot Pressing Temperature | Hot Pressing Pressure | Hot Pressing Time |

PES | 140-150℃ | 3-5kgf | 12-15s |

TPU | 130-140℃ | 2-4kgf | 12-15s |

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang