- info@cnygm.com

- +(0)86-576-88122360

Reflective Heat Transfer

Your Trustworthy Reflective Heat Transfer

Manufacturer Supplier

Your Reliable Reflective Heat Transfer Supplier

Multiple Types | Customized Stripes & Logos

What exactly is reflective heat transfer?

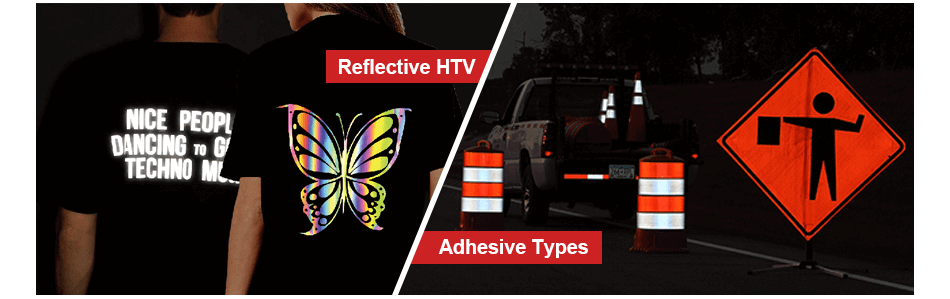

- Reflective heat transfer, popularly known as reflective HTV, is a specialty vinyl polymer that can be knife-cut or laser-cut into various designs such as graphics, stripes, logos, and so on.

- This vinyl polymer can be hot-pressed onto several different things such as t-shirts,backpacks, shoes, and so on to create innovative designs.

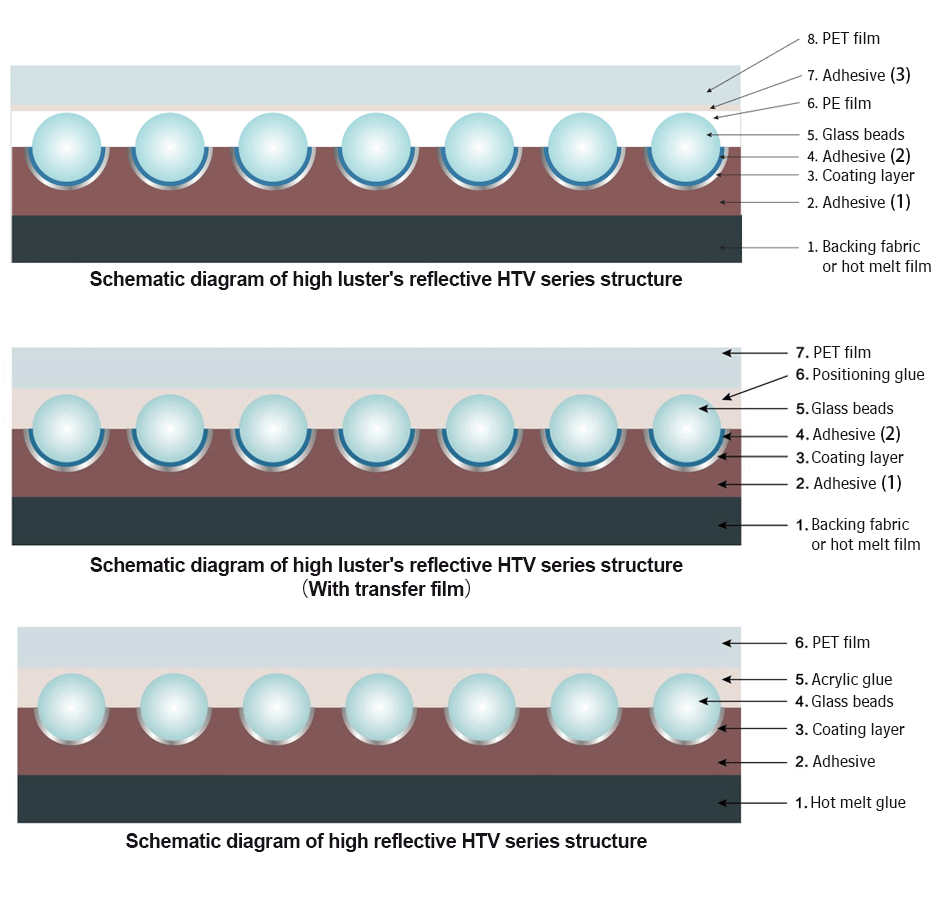

- The backing fabric that is used for custom reflective heat transfer is either PES or TPU.

- PES: PES is ideal for being hot-pressed onto cotton, woven fabric, and so on.

- TPU: TPU is perfect for being hot-pressed onto PU fabric, PVC fabric, and so on.

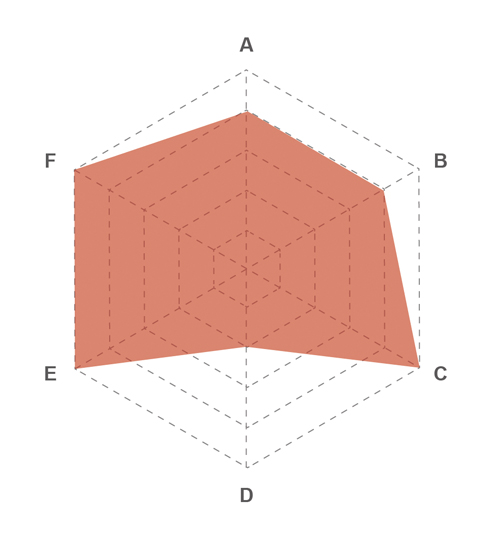

Reflective Heat Transfer Feature

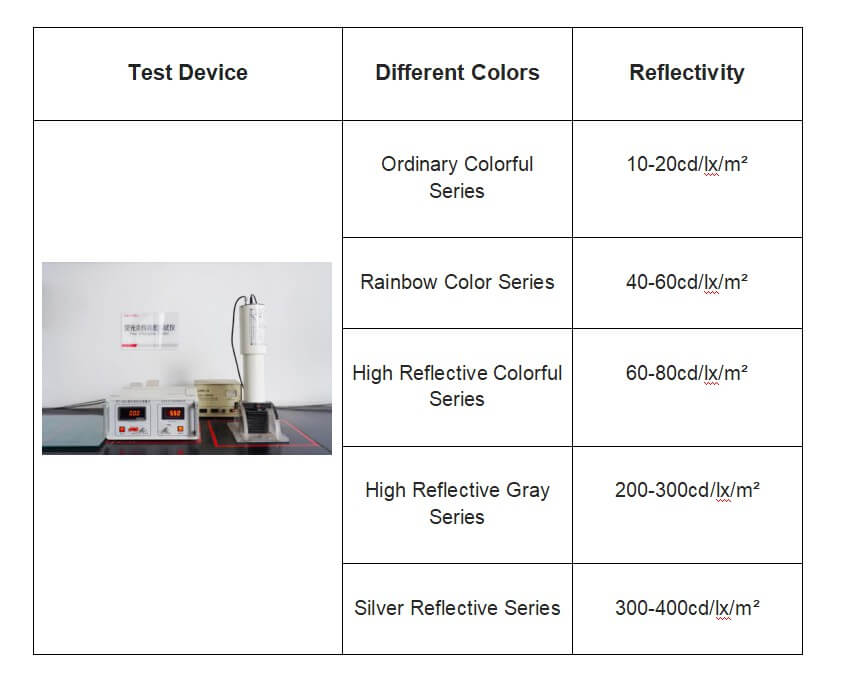

A:Reflectivity

Our reflective heat transfer is available in a range of colors, each with varying reflectivities.

• Silver, which comes with a reflectivity of 300-400cd/lx/m².

• Gray, which displays a reflectivity of 200-300cd/lx/m².

• Highly reflective colors reveal around 60-80cd/lx/m².

• The rainbow color is built with a reflectivity of about 40-60cd/lx/m².

• Ordinary colors reflect about 10-20cd/lx/m²

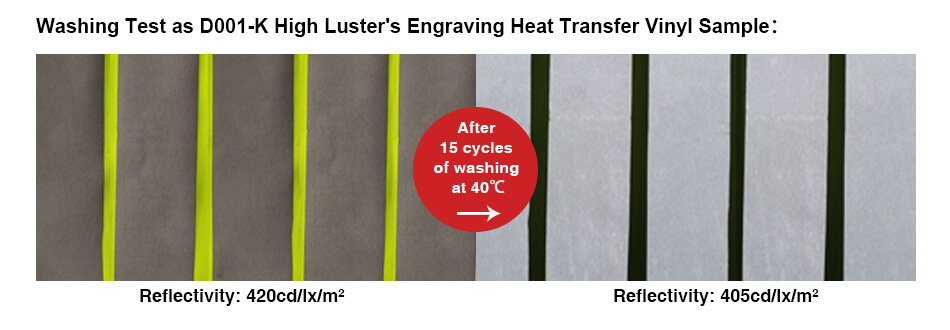

C:Washability

There are various ways in which you can wash your custom reflective heat transfer. You can either home wash it, perform industrial cleaning, or even hand it in for dry cleaning. You need to choose the washing method according to the specific products. Our custom reflective heat transfer comes with a washability of around 50 cycles.

E:Customizability

You can personalize your custom reflective heat transfer in several ways. You can either perform laser cutting to brand your fabric uniquely or cut it into stripes to craft the graphics or logo you want. Of course, you can also customize your reflective heat transfer for color and size as well!

B:Color

Different colors are built to have different amounts of reflectivity. Sheen and luster are what determine the reflectivity in colors. For instance, silver, which is extremely lustrous and shiny, is one of the highest reflecting colors. Similarly, Yellow/Silver/Yellow and Red/Silver/Red, followed by Grey, are highly reflecting colors. Ordinary color series, on the other hand, have lower amounts of reflectivity.

D:Flame retardancy

One of the unique features of reflective heat transfer is flame retardancy, or the ability to reflect fire. This ability is found in two color arrangements - the Red-Silver-Red and Yellow-Silver-Yellow.

F:Applicability

The reason reflective heat transfer is so popular can be attributed to the huge number of applications that it has. You can use custom reflective heat transfer for several different textiles, including t-shirts, bags, shoes, caps, and hats. Or you can get funky and fashionable with your fabrics and laser-cut or knife-cut whatever graphic you want onto your clothes. You can also show off the unique logo of your brand with our range of custom reflective heat transfer!

Why choose YGM Reflective Heat Transfer?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Reflective Heat Transfer Category

High Luster's Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:PES/TPU

● Hot Pressing Temperature:125-135℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:The PES type can be hot-pressed on cotton, woven fabric etc., while the TPU type can be hot-pressed on PU fabric, PVC fabric, and so on.

High Luster's Engraving Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:PES

● Hot Pressing Temperature:125-135℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:With excellent air permeability, this HTV is perfect for all kinds of lettering - which can then be hot-pressed onto cotton, woven, and other fabrics.

High Luster's Industrial Wash Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:TPU

● Hot Pressing Temperature:110-135℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:With one of the best washing performances, this reflective heat transfer can be hot-pressed onto PU, PVC fabric etc.

High Luster's Flame Retardant Elastic Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:TPU

● Hot Pressing Temperature:110-135℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:This reflective heat transfer is known for its elastic nature and good flame retardancy, so it is suitable for flame retardant fabric and elastics.

High Luster's Elastic Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:TPU

● Hot Pressing Temperature:110-135℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:With excellent elasticity, high luster's elastic reflective heat transfer is suitable for all kinds of elastic woven tapes, as well as for hot pressing onto fabrics such as PVC or PU.

High Luster's Printable Reflective Heat Transfer

● Reflectivity:>400CPL

● Color:Silver

● Backing Fabric:PES

● Hot Pressing Temperature:130-140℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:This vinyl works brilliantly for lettering and hot pressing onto cotton, woven fabrics, and so on. This custom reflective heat transfer can be directly used for surface printing.

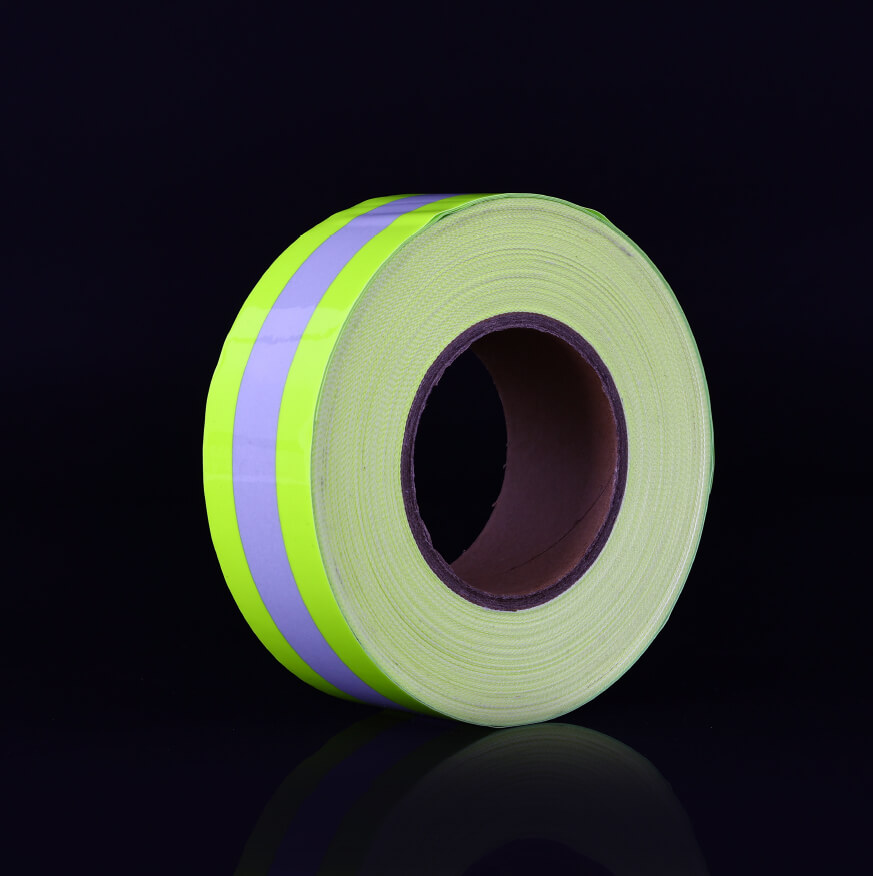

High Luster's Fluo-Yellow Warning Reflective Heat Transfer

● Reflectivity:>300CPL

● Color:Yellow-Silver-Yellow

● Backing Fabric:PES

● Hot Pressing Temperature:130-140℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:This heat-resistant vinyl has super high flame retardancy, which is why it can be used in fields where protection from fire is necessary. It can therefore be used in places such as the electrical industry. This custom reflective heat transfer is suitable for hot pressing onto cotton, woven fabric, and so on.

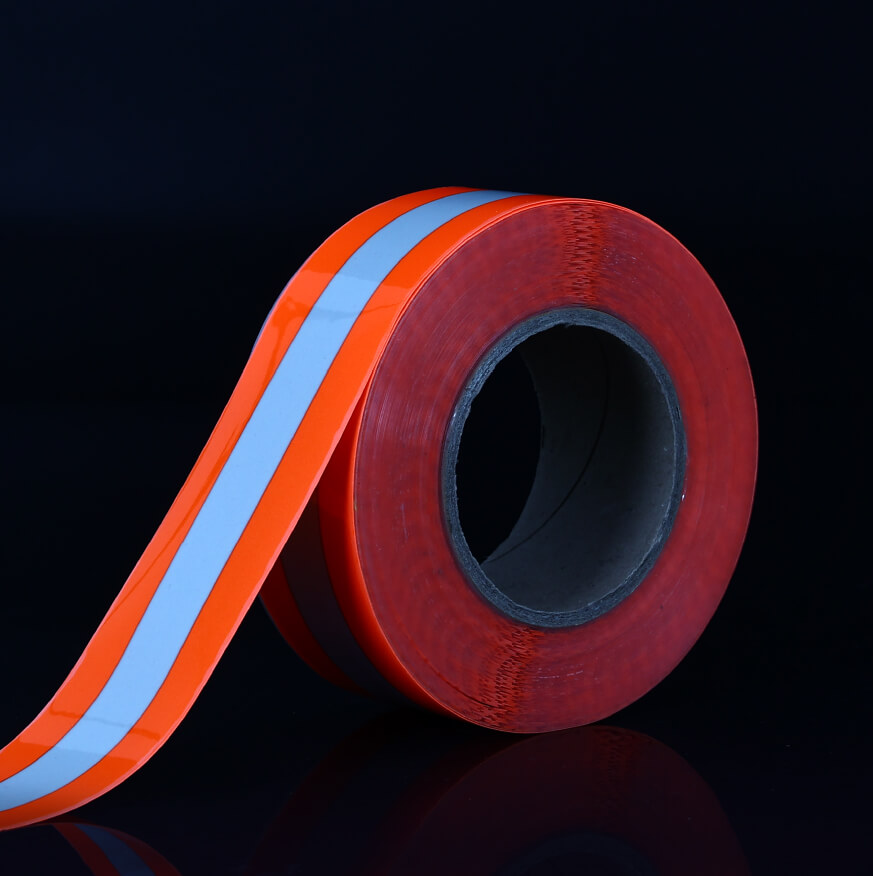

High Luster's Fluo-Red Warning Reflective Heat Transfer

● Reflectivity:>300CPL

● Color:Red-Silver-Red

● Backing Fabric:PES

● Hot Pressing Temperature:130-140℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:This is yet another heat-resistant vinyl that can be hot-pressed onto cotton, woven fabric, and so on. With high flame retardancy, this reflective heat transfer can be used in fields where protection from fire is necessary. It is, therefore, suitable for places such as the electrical industry.

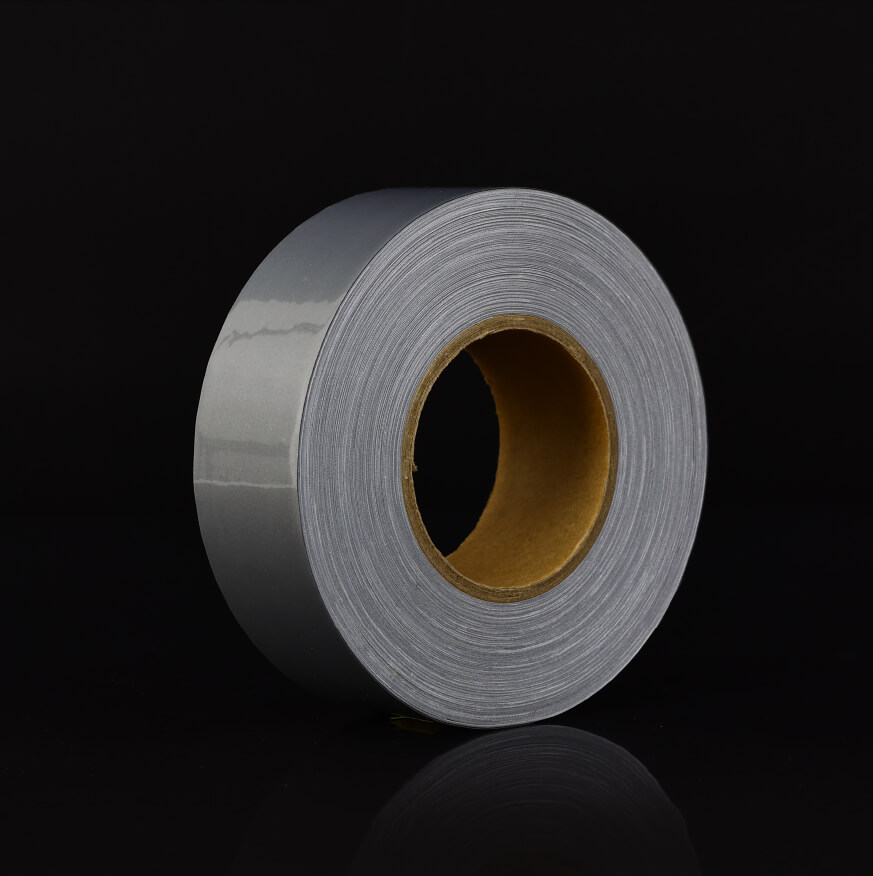

High Reflective Heat Transfer

● Reflectivity:>300CPL

● Color:Grey

● Backing Fabric:PES

● Hot Pressing Temperature:120-130℃

● Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application: This custom reflective heat transfer is perfect for being hot-pressed onto fabrics such as woven fabric, cotton, etc.

High Reflective Engraving Reflective Heat Transfer

● Reflectivity:>300CPL

● Color:Grey

● Backing Fabric:PES

● Hot Pressing Temperature:125-135℃

●Hot Pressing Time:8-15s

● Hot Pressing Pressure:2-3kg/cm²

● Application:Since high reflective engraving reflective heat transfer has good air permeability, it is perfect for lettering and then being hot-pressed onto fabric such as cotton, woven, and so on.

Colorful Reflective Heat Transfer

● Reflectivity:>15CPL

● Color:Any color

● Backing Fabric:PES

● Hot Pressing Temperature:130-150℃

● Hot Pressing Time:10-15s

● Hot Pressing Pressure:3-5kg/cm²

● Application: This reflective heat transfer is excellent for being hot-pressed onto fabrics such as woven fabric, cotton, etc.

Rainbow Reflective Heat Transfer

● Color:Rainbow color

● Backing Fabric:PES

● Hot Pressing Temperature:140-150℃

● Hot Pressing Time:15-20s

● Hot Pressing Pressure:3-5kg/cm²

● Application: Rainbow reflective heat transfer is brilliant for being hot-pressed onto fabrics such as woven fabric, cotton, etc.

Reflective Heat Transfer:The Complete FAQ Guide

Table of Contents

What is reflective heat transfer?

Reflective heat transfer, or reflective HTV as it is more commonly known, is a specialized vinyl polymer used to design various patterns on fabrics and surfaces. It can either come in a single color or various colors, such as rainbow colors, to produce unique objects for advertising. Reflective HTV is extremely simple to use. Since it comes in a sheet or roll package along with another backrest, it can be hot-pressed onto any substrate or surface after being trimmed and weeded according to your needs.

What purpose does reflective heat transfer serve?

Reflective material products are used in the design and manufacture of various reflective materials, including reflective heat transfer, reflective sheeting, reflective fabric, reflective thread, PVC reflective fabric, reflective pattern fabric, reflective woven/oxford tape, and so on.

Reflective products play a vital role in maintaining road traffic safety as well as outdoor safety. They are also excellent for reflecting the fashionable personality of yourself and your brand. This is why you will find reflective materials being used on various products, including clothing, accessories, logos, caps, vests and jackets, gloves, and even school uniforms.

With a perfect blend of fashion, beauty, and safety, custom reflective heat transfer is one of the most reflective materials out there with several benefits. The various advantages of reflective heat transfer are:

- It is Non-Destructive- custom reflective heat transfer is an extremely smooth and non-destructive product that does not damage the function of the carrier product in any manner during application. For instance, if you have a waterproof fabric that you wish to use reflective vinyl on, you can easily do so without affecting the waterproof performance of the fabric. There is also no need for you to conduct auxiliary or special treatment for the waterproof reflective tapes that you use.

- Simple and Easy Processing- all you need is a cutting plotter or a laser machine in order to engrave various designs on your custom reflective heat transfer.

- It lays on smoothly and flatly- reflective heat transfer tends to be a lot more compliant than silk screen printing. Your patterns and stripes are super smooth and aesthetically pleasing when hot-pressed onto the fabrics.

- It is Dynamic- Because of its dynamic nature, custom reflective heat transfer is used by popular sports brands such as Adidas and Nike to embellish their sportswear. This vinyl is perfect for showing off your fashion, even in things such as sports shoes.

What are the standards of quality when it comes to reflective heat transfer?

1. Surface Color- The reflective heat transfer typically comes in a range of traditional colors such as yellow, red, and green. You will also find a rainbow color. Good quality custom reflective heat transfer is super seamless, which means that no matter which angle you look at it from, you will not find any white spots, black spots, or bubbles on the surface.

2. Reflectivity- Different colors come with different levels of reflectivity. You will be able to use professional equipment such as inverse reflection coefficient measuring instruments to detect your chosen color’s level of reflectivity accurately. Simply put, the level of reflectivity depends upon the darkness of the color. This means that lighter colors have greater reflectivity while darker colors have lower reflectivity. Take a look at the below table for a better understanding.

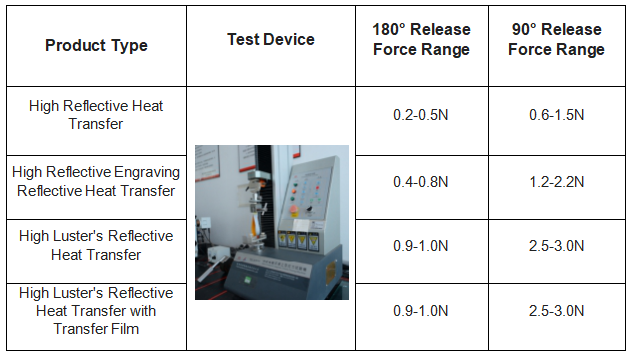

3. Release Force- The release force is the strength of the adhesive present between the surface protective layer and the reflective layer. This is why the release force is also sometimes known as adhesion strength. The force is usually released at an angle of either 90 degrees or 180 degrees. You will be able to determine the release force of your vinyl with special instruments such as tensile testing machines. You need to know this value because the release force is vital to monitor cutting logos and hot pressing. Take a look at the table below to understand the release forces for various product types.

Note: Since different products either come with the transfer film or non-transfer film, they all have different release forces.

4. Washing Performance- the directions for washing depend upon the nature of the custom reflective heat transfer that you choose. For instance, some products require European standard ISO6330 washing (40°/60°C) and dry cleaning, including handwashing, ordinary washing, and machine washing. However, one of the best performing washes for reflective heat transfer products remains the ISO15797 Industrial Washing.

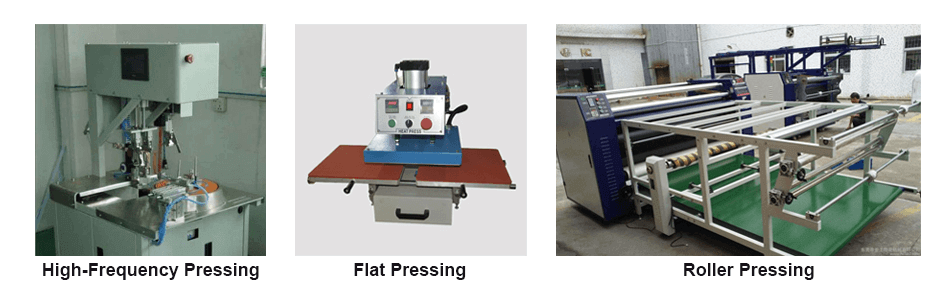

5. Pressing Method- There are several variations in material, operating environments, and machinery for pressing vinyl products, which is why it is important for you to follow the operating requirements that we provide. However, the three main pressing methods available are roller pressing, flat pressing, and frequency pressing. You also need to keep in mind that the safest operating pressure for reflective heat transfer is <5kg/cm² and safest operating temperature is <200°C.

What are Some Common Applications of Reflective Heat Transfer?

With highly unique qualities, reflective heat transfer is one of the most applicable products that can be used for a variety of cases. Take a look at the table below to understand some of the common applications:

Product Name | YGM Model Number | Application | Reference processing conditions | ||

Hot Pressing Temperature(℃) | Pressure | Time | |||

High Luster’s Reflective Heat Transfer | WD001 | You can cut this product into different kinds of logos or strips, which is why this is perfectly suitable for hot pressing onto webbing, polyester, T/C, and other fabrics. You can also hot press it onto safety clothing. | 130-150 | ﹥2kg/cm² | 12-15s |

D001M | |||||

D001 | |||||

D001-D | |||||

D001-GS | |||||

D001-FT | Since the material of this product is extremely scratch-proof and wear-resistant, it is suitable for being hot-pressed onto fabrics meant for rough use, such as bags and shoes. | 130-150 | |||

High Luster’s PU Reflective Heat Transfer | D001-P | This reflective vinyl can be used to hot press on PVC and PU fabric. Please note that this fabric cannot remain soaked in water or washed in the machine for too long. The best way to watch this fabric would be to scrub it with water. ( D001-DP is scratch-resistant) | 120-130 | ||

D001-DP | |||||

High Luster’s Engraving Reflective Heat Transfer | D001-K | This product can be used to hot press onto webbing, T/C, polyester and so on and is perfect for engraving patterns and lettering. | 130-150 | ||

High Luster’s Elastic Reflective Heat Transfer | D004-7D | This custom reflective heat transfer is perfect for being hot-pressed onto general elastic fabrics. | 130-150 | ||

D004-7P | This product is best applicable for being hot-pressed onto high elastic fabrics and elastic bands. | 120-130 | |||

High Luster’s Flame Retardant Reflective Heat Transfer | D001-H | This custom reflective heat transfer is perfect for being hot-pressed onto flame retardant fabrics with average washing performance. | 130-150 | ||

D001-H-GS | This custom reflective heat transfer is perfect for being hot-pressed onto flame retardant fabrics with high washing performance. | 130-150 | |||

D001-H-GS | 130-150 | ||||

DH102-12 | 130-150 | ||||

Colorful Series Reflective Heat Transfer(High Luster’s and ordinary reflective) | D201-X | This reflective heat transfer can be used to hot press onto webbing, T/C, polyester, and so on and is perfect for engraving patterns and lettering. | 130-150 | ||

High Reflective Heat Transfer | D101-A | Good for hot pressing onto webbing, polyester, T/C, and other fabrics. | 130-150 | ||

D101 | Ideal for hot pressing onto webbing, polyester, T/C, and other fabrics. | 130-150 | |||

High Reflective Engraving Reflective Heat Transfer | D101-K | This custom reflective heat transfer product is good for hot pressing onto webbing, T/C, polyester, and so on and is perfect for engraving patterns and lettering. | 130-150 | ||

Is it possible to apply wet reflective heat transfer?

No, it is not advisable to apply wet reflective heat transfer. This is because the product contains a metallic aluminum layer that prevents the capacity for airing. If you apply the product wet, the moisture ends up getting trapped beneath the surface.

Applying it wet will void any warranty that you have, mainly because whatever wet solution you use will create an imbalance in the pH balance.

The moisture may also react with the metallic layer and cause the material to break down or corrode. Further, wet applications are also going to compromise significantly the adhesive quality of the product.

However, there are some cases when it becomes inevitable for you to apply it wet. For instance, if you are applying custom reflective heat transfer on the surface of a vehicle on a hot and humid day, then it is impossible for you to apply it in a dry manner.

In such cases, it is essential to use minimal wet solutions and use a squeegee to remove as much moisture as you can from the surface.

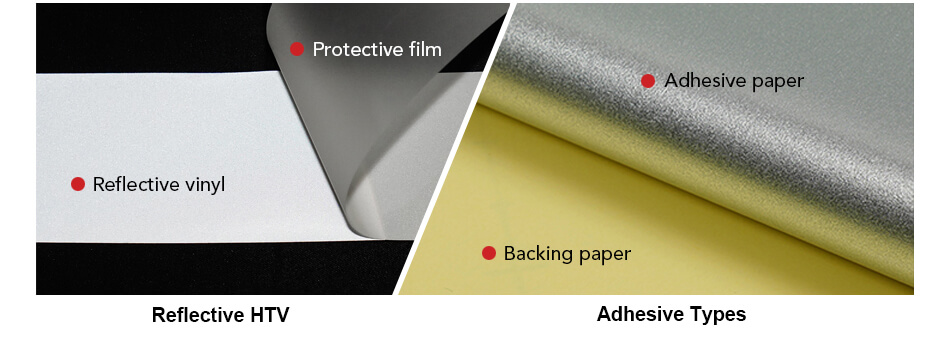

What is the difference between adhesive tape and reflective heat transfer?

- The backing is different –

You will find adhesive tape in all kinds of finishes and colors – but they all have the same kind of backing. This is a paper backing that is sticky to the touch when peeled off.

Reflective heat transfer, on the other hand, has a clear plastic carrier sheet covering the top of the surface instead of the paper backing.

● The usage is different –

It is possible for you to directly stick the adhesive tape on the surface, but when it comes to custom reflective heat transfer, you need to hot press it onto the fabric.

How do you test the standard of the reflective heat transfer?

1. The surface needs to be smooth without any spots.

2. Once you remove the protective film, you can check whether there are any glass beads on it or not.

3. The extra material from the logo needs to be easily weeded off after engraving it.

4. Once you hot press custom reflective heat transfer, rub the surface with your fingers to check whether any glass beads form.

5. It is important for your custom reflective heat transfer not to have any wrinkles after hot pressing.

How do you make use of reflective heat transfer?

There are several ways in which you can use custom reflective heat transfer depending upon which industry you are operating in. For instance, since custom reflective heat transfer is safety-certified, it can be used on the uniforms of security personnel, firemen, and policemen. This product is great for these uniforms because it also shines bright in dim or dark areas.

The reflective heat transfer that is used for safety uniforms is usually cut into different sizes of strips. You can customize the width of the strip, or even cut it into logos or any other pattern. Make sure to remove the excess material before setting your iron to “cotton mode” and hot pressing for 15 to 20 seconds. Ensure that you cover the entire surface during hot pressing. Once the product has cooled for a few seconds, you can remove the protective film. And there you have it! Using custom reflective heat transfer is as simple as that!

What do I need to know before I order reflective heat transfer?

Before you order reflective heat transfer, you need to understand your application field. This is because you will select the kind of pattern you want according to the application field.

Next, select an appropriate pattern for your custom reflective HTV. If you choose to cut it into stripes, there are no blade criteria for you to follow. All you need to do is just pick out the appropriate product and hot press it onto the fabric.

In case you choose to cut your custom reflective heat transfer into logos, then there are two options for you to use. You can either use a laser machine or a plotter for your custom reflective heat transfer. Both PES and TPU reflective heat transfer can be used with the laser machine, but it would be better for you to choose the one with the PES backing when it comes to the plotter. TPU tends to be sticky, and it might get trapped on the blade while heating.

Once you have selected the backing, it’s time for you to think about aspects such as washing performance, wear resistance, flame resistance, hardness, and efficiency. Follow the recommendations we have on our website and you will be able to find the most appropriate product for you. You can also reach out to our customer support representatives for help in picking out your product.

How do you cut reflective heat transfer?

There are two different ways in which you can cut custom reflective heat transfer. You can either cut it into strips or cut it into logos.

If you are thinking about cutting your custom reflective heat transfer into strips, you can use either the plotter or the laser machine to do so. Since there are no blade prerequisites, you can use either the plotter or laser machines to cut both TPU and PES backing. Cutting custom reflective heat transfer into strips is extremely simple and does not require complicated operations.

If, on the other hand, you decide to cut your reflective heat transfer into logos, then it is essential for you to use professional equipment. For instance, you can use cutting machines such as Cricut or Silhouette Cameo 3 to cut your reflective HTV into logos.

Choose your preferred cutting app and open up the design on the application. You first need to scale your design with the right dimensions and then imitate the design that you want while cutting. Please note that whenever this reflective heat transfer is added to your fabric, you need to turn it in the opposite direction before hot pressing it.

What is the purpose of the Transfer Film in the reflective heat transfer?

- The transfer film in the reflective heat transfer is present to keep your logo/pattern in place.

- It allows you to hot press on to the surface in a comfortable and convenient manner because of its transparent and sticky nature.

- The transfer film is also great at preventing the biting of the cloth. This is because the material that is used in the protective film is PET + PE. While the PE is capable of melting at higher temperatures (which helps it stick to the fabric), the PET does not melt at higher temperatures.

- Customers can also use a transfer film for various other purposes as well.

How can I check the quality of my reflective heat transfer?

- Check whether you can cut it into a strip or a logo.

- Check whether there is a separation between the grey vinyl and the protective film.

- Check whether any glass beads fall off from the surface when you remove the protective film.

- Try washing your custom reflective heat transfer as per the ISO6330 to check its durability.

How can I stick my reflective heat transfer well?

- Determine the kind of fabric you are going to be using as well as the reflective heat transfer product you want.

- Understand the best hot-pressing pressure, temperature, and time for that particular product.

- Make sure you hot press your custom reflective heat transfer under all of the right conditions and cover the entire product.

- Allow it to cool for a few seconds before tearing off the protective layer.

- Turn the heat down slightly and then press the button once again for about 12 to 15 seconds. Ensure that the vinyl is completely smooth.

Why is my reflective heat transfer not sticking?

- The hot-pressing pressure, time as well as temperature are all extremely important conditions you need to fulfill when using custom reflective heat transfer. Make sure that you follow the directions provided on your product and check whether all of your settings are correct or not.

- Time: Ironing the vinyl for too short might not be enough for the vinyl to stick, while ironing it for too long might burn the adhesive.

- Temperature: each vinyl product requires a different temperature setting for hot pressing. Make sure that you are following the standard temperature conditions.

- Pressure: you need to put a good amount of pressure while ironing your custom reflective heat transfer. The best way to tell whether you have perfect pressure or not is to check whether you are able to see the weave of the cloth through your vinyl product or not.

- Make sure you are using the right kind of cloth for your reflective HTV. For instance, it is important for you to use spandex for TPU and PES type for logos.

- It might be difficult for your reflective HTV to stick on to buttons, thick seams, and zips.

- There are some kinds of HTV where the carrier needs to be peeled off immediately after being hot pressed. Others might require you to wait before removing the carrier sheet. No matter when you peel plastic the carrier sheet, ensure that you are not destroying the design in the process.

How durable is reflective heat transfer?

Vinyl that has been ironed onto a t-shirt is most likely going to last as long or longer than the t-shirt itself.

The best way to ensure the durability of your custom reflective heat transfer is to turn your clothes inside out before washing. Always use cold water and make sure that you are not scrubbing too hard over the vinyl.

What material should we use reflective heat transfer on?

It is important for the melting point of your material to be greater than 140°C, since custom reflective heat transfer needs to be hot-pressed onto the surface at 120-140°C.

If you are using the TPU backing (which is highly elastic), make sure that you use it for elastic fabrics such as PVC and PU. On the other hand, if you are using the PES backing, ensure that you use fabrics such as polyester, cotton, webbing, nylon, etc.

Take a look at the below table to understand the features of TPU and PES.

PES | TPU | |

Composition | polyester | thermoplastic polyurethane |

Transparency | white translucent | transparent, translucent, matte |

Elasticity | general | very good |

Soft and comfortable | general | very good |

Washing | very good | general |

Dry cleaning | very good | general |

Temperature resistance | Good high temperature resistance | good low temperature resistance |

Hot pressing temperature | 140-150℃ | 130-140℃ |

What is the Difference Between Reflective Heat Transfer and Reflective Tape for Sewing?

- The carrier sheet (PE/PET PET film, clear safety film or composite film) of custom reflective heat transfer is usually peeled off after hot pressing, while the carrier sheet of reflective tape for sewing is peeled off during manufacturing itself.

- The substrate of custom reflective heat transfer is made of hot melt adhesive films such as TPU or PES, while the reflective tape substrate is made of T/C, 100% polyester, 100% cotton, 85% polyester+15% spandex or 100% aramid.

- Reflective Heat Transfer can be used to hot press customized logos and patterns onto various fabrics and garments, while reflective tape for sewing is used to stitch safety clothing. After the application of surface water repellents, the reflective fabric can also be used to design reflective umbrellas.

How do you iron reflective heat transfer?

- Design a template on your computer application.

- Lay the transparent side of the carrier sheet down and cut the vinyl with the help of a laser or a knife plotter.

- Weed the excess material.

- Place the custom reflective heat transfer on your fabric with the transparent side of the carrier sheet facing up. Hot press for about 12 to 15 seconds at 120°C-140°C and apply 2-3kg/cm² pressure.

- Allow the vinyl to cool for 30 seconds.

- Tear off the protective layer.

- If you notice any areas lifting after the application process, hot press it once again.

What Problems might I face while Using Reflective Heat Transfer and how do I overcome them?

- Layered Vinyl, i.e., the reflective heat transfer has not been firmly applied on the fabric.

To overcome this problem,

- Ensure that you follow the right instructions for hot-pressing pressure, temperature and time.

- Usage time and storage conditions of the hot melt adhesive needs to be as follows:

- Temperature: 15-30℃, shelf life: 1 year, humidity: <60%.

- Check whether the fabric is oil/water resistant.

- Problems with the hot melt adhesive and glue layer.

To overcome this problem,

- Ensure that you follow the right instructions for hot pressing temperature and pressure.

- Falling Glass Beads

To overcome this problem,

- Ensure that you follow the right glue curing time and apply enough strength.

- The extra vinyl did not peel off perfectly after the logo was cut.

To overcome this problem,

- Ensure that you set the power of the logo cutting machine properly.

- After the hot pressing, the custom reflective heat transfer peeled off along with the transfer film.

To overcome this problem,

- Ensure that you follow the right glue curling time and apply enough strength and intensity.

- Make sure that the transfer film does not have too strong a peeling force.

- The glass beads should not be embedded too deep.

What temperature should I set the hot press on for reflective heat transfer?

The hot pressing temperature varies according to the custom reflective heat transfer backing materials. Take a look at the below table for reference.

Backing Fabric | Hot Pressing Temperature | Hot Pressing Pressure | Hot Pressing Time |

PES | 140-150℃ | 3-5kgf | 12-15s |

TPU | 130-140℃ | 2-4kgf | 12-15s |

What kind of reflective heat transfer does YGM offer?

The Main series offered at YGM include:

-Silver reflective heat transfer

-Colorful reflective heat transfer

-Grey reflective heat transfer

-Rainbow reflective heat transfer

Can I order custom reflective heat transfer from YGM?

Yes, you definitely can.

What is the size of YGM's reflective heat transfer?

The regular width of our custom reflective heat transfer is either 5cm, 50cm or 1m. You can also customise the size of your HTV according to your requirements.

Can I order custom-specifications for my reflective heat transfer?

Yes, you can customise your reflective HTV according to your requirements.

How long does it take for my order to be delivered?

Orders are usually delivered within 25 to 35 days.

Do you offer any free samples?

Yes, we offer free samples, but we charge you for freight. Once you have confirmed your order, freight charges will be deducted.

Is it necessary for me to pre-order or wait for new stock?

Stock is usually available for regular products. Products are made to order for custom specifications.

Are there certification standards for reflective heat transfer? Do they need to be updated?

Yes, the certificate is: Oeko-Tex Standard 100, ENISO20471.

We will renew and update the certificate on a regular basis.

How do I make sure the reflective heat transfer stays in good shape?

Make sure you follow the specified criteria for both hot pressing and washing.

What is the total production capacity of reflective heat transfer at YGM?

We produce about 5 million SQM reflective heat transfer every month.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang