- info@cnygm.com

- +(0)86-576-88122360

Your Reliable Hi Vis Iron On Tape

Multiple Types | Customized Stripes & Logos

- Based out of China, YGM stands for 夜光明, pronounced as Yè-Guāng-Míng. These three Chinese words stand for night, light, and bright, loosely translating to “bright light in the night”. With over 16 years of experience, YGM is considered one of the most successful and creative manufacturers of reflective tape, fabric, and material. They have over 30 production lines, more than 300 competent staff, and five well-operating facilities to their name.

- The multiple warehouses of YGM, where most of the production takes place, produce the best-quality iron on hi visibility tape. These production houses are equipped with the latest, up-to-date amenities that ensure the proper manufacturing and storage of millions of reflective material — from fabrics to sheets to vests, tapes, and more.

- YGM’s well-seasoned quality control process promises that every product given out to the customer is of excellent quality, nothing short of the very best in town. Owing to the process and work put behind every product produced by YGM, the brand has successfully managed to bag several certificates and accolades under its hat.

- Some of the added benefits that come when you purchase with YGM are as follows:

- You can customize the design of the hi vis iron on tape to best suit your needs.

- The products are ISO 9001, ISO14001, ISO18001, ISO16949, EN ISO 20471, EN11612, EN14116, EN469, EN14119, and OEKO certified.

- Each roll of the product is traceable.

- The products support both home wash and industrial wash.

- Therefore, next time you are looking for a reliable supplier of hi vis iron on tape, do not think twice before reaching out to and inquiring about the product to YGM.

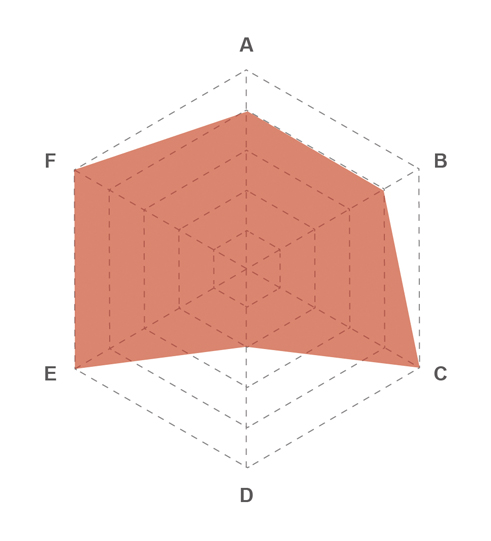

Hi Vis Iron On Tape Feature

Some of the characteristics of hi vis iron on tape are as follows:

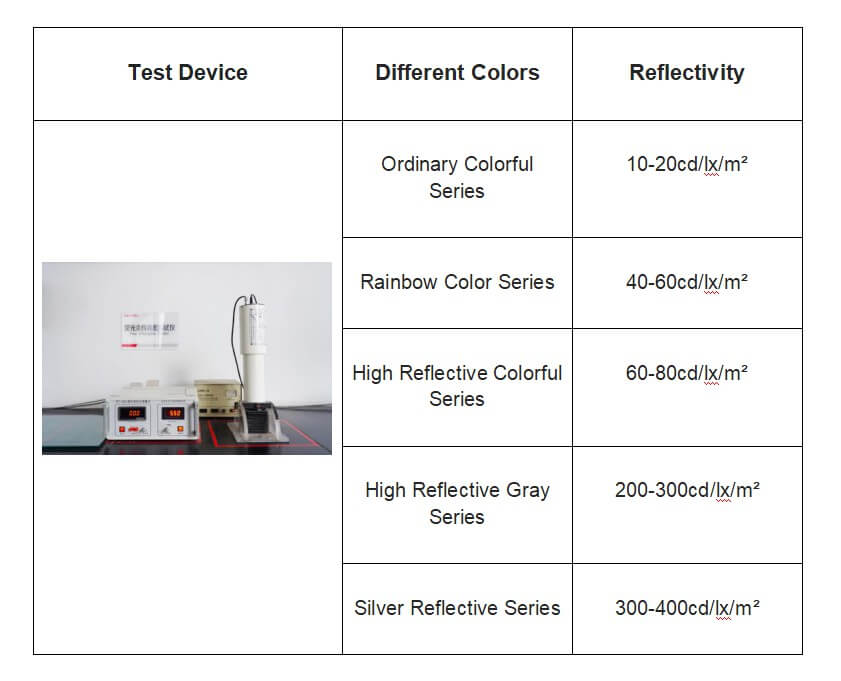

A:Reflectivity

The hi vis iron on tape comes in different colors, each denoting a different level of reflectivity. The color, with their reflectivities, are as follows:

- Silver: 300-400cd/lx/m²

- Gray: 200-300cd/lx/m²

- Rainbow: 60-80cd/lx/m²

- Ordinary: 10-20cd/lx/m²

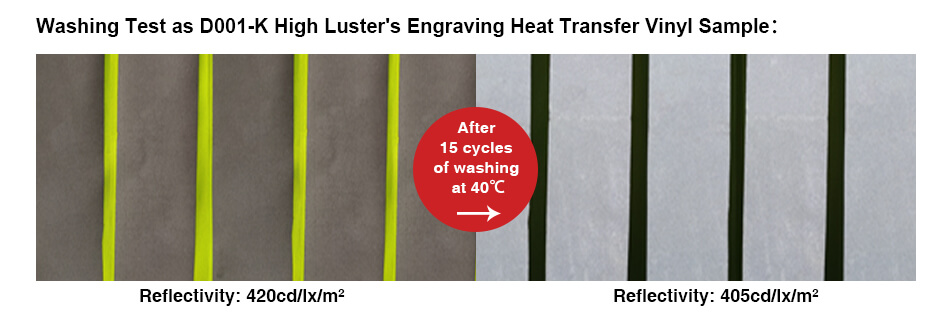

C:Washability

Depending on the necessity and your suitable mode of preference, the iron on hi visibility tape fabrics can be washed in three ways, with a washability of up to 50 cycles. The three ways are through:

- Home wash

- Industrial wash

- Dry cleaning

E:Customizability

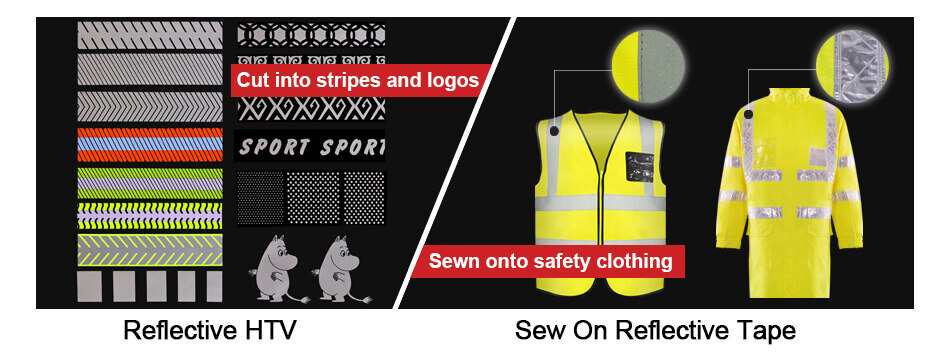

You can make your hi vis iron on tape distinct and unique through different modes of customization. You can subject the product to laser-cutting, get it cut into stripes, and get the size and color of the product personalized.

B: Color

Different colors denote different levels of reflectivity. Silver, Yellow/Silver/Yellow, and Red/Silver/Red, followed by the color grey, and so on and so forth, are some of the highest reflecting colors. Colors out of any ordinary color series belong to the category of low-reflecting colors.

D:Flame retardancy

Hi vis iron on tape with the color arrangement of Yellow-Silver-Yellow, and Red-Silver-Red are most likely to reflect fire.

F:Applicability

The various applications of iron on hi visibility tape include the following:

- It can be used for hot pressing on fabrics like bags, hats, t-shirts, other garments, caps, and various other textiles.

- It can be used to laser-cut or knife-cut the logo of your brand on your brands’ supplies and products.

Why choose YGM Hi Vis Iron On Tape?

You must be wondering why to choose YGM to get your supply of iron on hi visibility tape? Well, they have established themselves as one of the pioneering brands when it comes to producing reflective heat products.

Keeping in view the motto of the brand, “make you bright, no matter where you go”, YGM has a team of competent, skillful professionals who work to produce extraordinary products that are best suited to meet your demands and needs.

YGM has over three R&D centers that are spread across the city. They have a cutting-edge research center in Taizhou with up to 15 engineers who look over research and development.

They have an extensive factory/workshop with 30 production lines and 5 facilities. The qualified personnel working here ensure that no compromise on the quality of the product is made. The factory stretches over 30,000-50,000 square meters over Binhai Industrial Park in Taizhou Economic Development Zone.

YGM has one of the best warehouses in the country that boasts all the required amenities and facilities. This warehouse is used to store millions of reflective materials.

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Hi Vis Iron On Tape Category

Hi vis iron on tape is further categorized into 12 types:

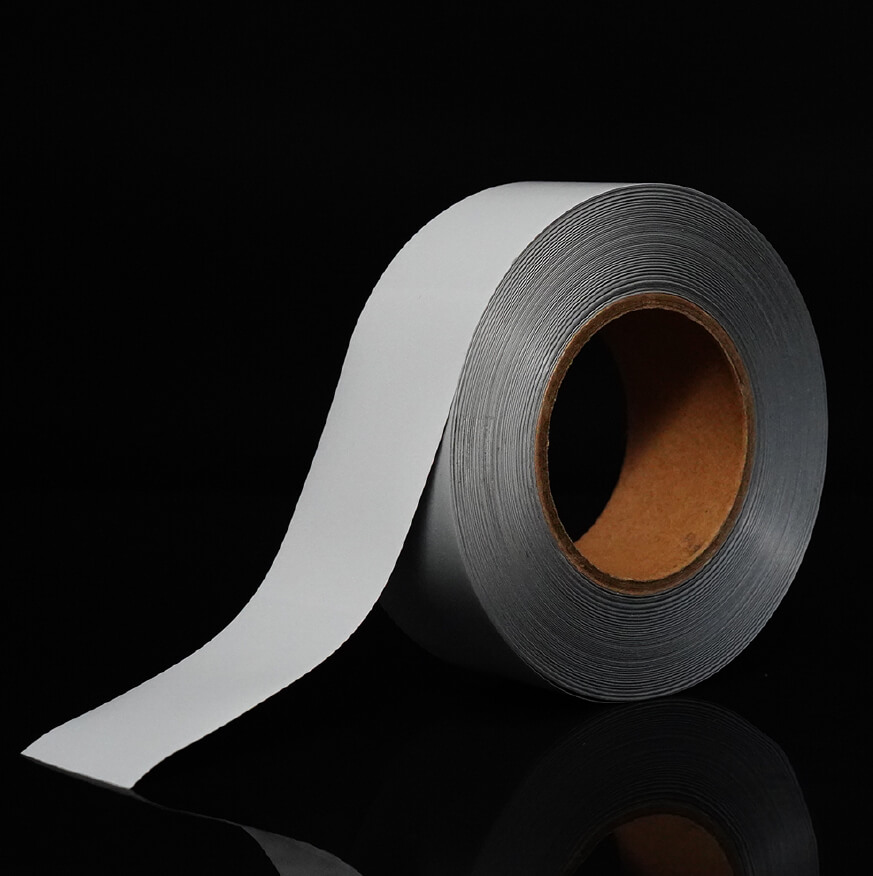

High Luster's Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: PES/TPU

- Hot Pressing Temperature: 125-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Application: PES type is ideal for hot pressing on woven and cotton textile. TPU type is suitable for hot pressing PU or PVC fabrics.

High Luster's Engraving Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: PES

- Hot Pressing Temperature: 125-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Benefit: Good air permeability.

- Application:Can be used for lettering and hot pressing on woven, cotton, and many other fabrics.

High Luster's Industrial Wash Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: TPU

- Hot Pressing Temperature: 110-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Good washing performance.

- Application: Best suited for hot pressing on PU, PVC, and similar fabrics.

High Luster's Flame Retardant Elastic Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: TPU

- Hot Pressing Temperature: 110-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Has good elasticity and high flame retardancy.

- Application: Best used for elastic and flame retardant fabrics.

High Luster's Elastic Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: TPU

- Hot Pressing Temperature: 110-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Incredibly elastic.

- Application: Suitable for hot pressing on PU and PVC fabrics and various elastic woven tapes.

High Luster's Printable Hi Vis Iron On Tape

- Reflectivity: >400CPL

- Color: Silver

- Backing Fabric: PES

- Hot Pressing Temperature: 130-140℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Application: This iron on hi visibility tape can be used for direct surface printing, lettering, and hot pressing on woven, cotton, and other fabrics.

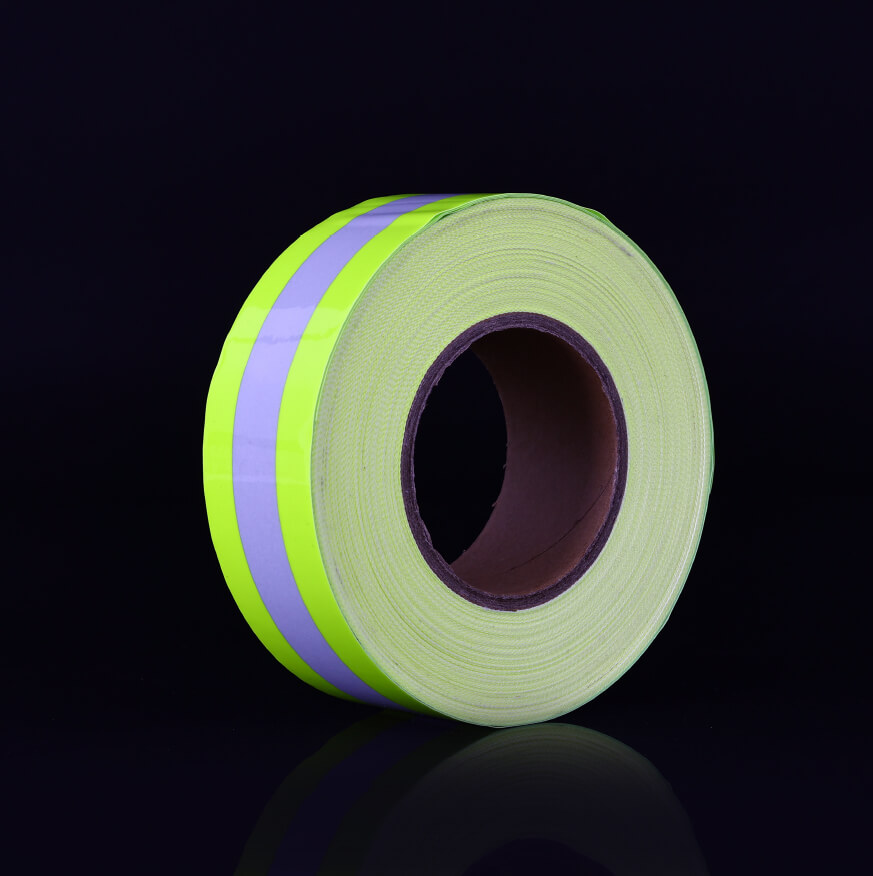

High Luster's Fluo-Yellow Warning Hi Vis Iron On Tape

- Reflectivity: >400CPL - Reflectivity: >300CPL

- Color: Yellow-Silver-Yellow

- Backing Fabric: PES

- Hot Pressing Temperature: 130-140℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Has a high flame retardancy and heat resistance.

- Application: Best used in fire and electrical industries. It can also be used for hot pressing on woven, cotton, and other fabrics.

- Color: Silver

- Backing Fabric: TPU

- Hot Pressing Temperature: 110-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Has good elasticity and high flame retardancy.

- Application: Best used for elastic and flame retardant fabrics.

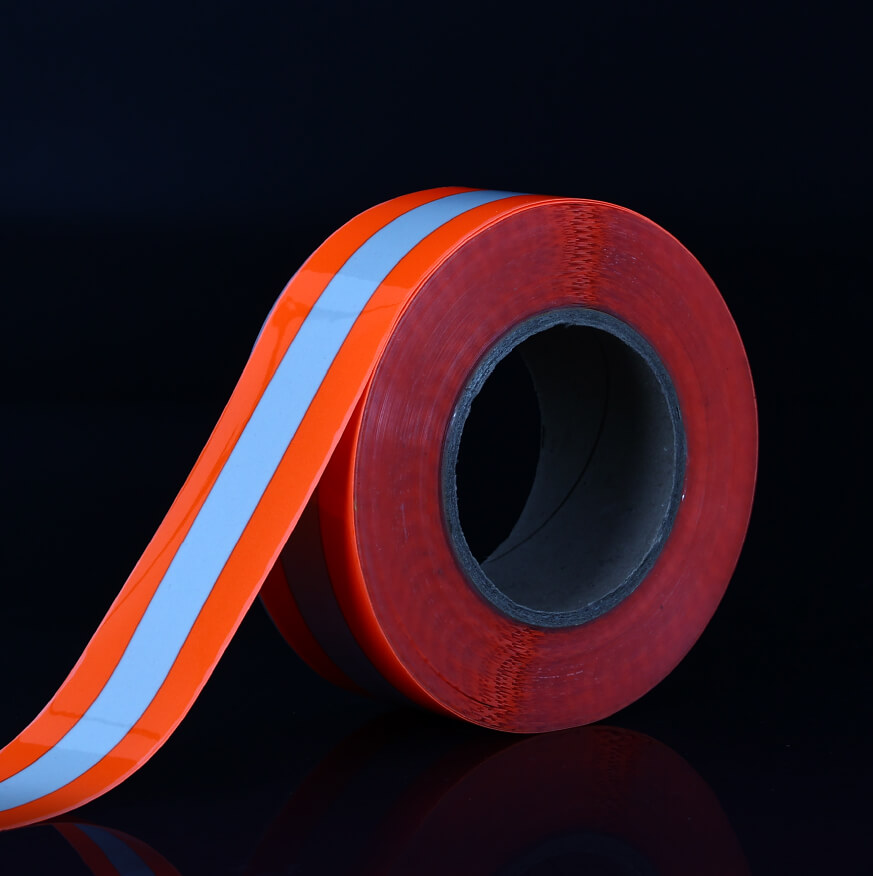

High Luster's Fluo-Red Warning Hi Vis Iron On Tape

- Reflectivity: >300CPL

- Color: Red-Silver-Red

- Backing Fabric: PES

- Hot Pressing Temperature: 130-140℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Resistant to high heat.

- Application: Ideal for putting in use in fields that require fire protection and electrical industries. It can also be used for hot pressing on woven, cotton, and other fabrics.

High Reflective Hi Vis Iron On Tape

- Reflectivity: >300CPL

- Color: Grey

- Backing Fabric: PES

- Hot Pressing Temperature: 120-130℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Application: Suitable for hot pressing on woven, cotton, and other fabrics, textiles, and garments.

High Reflective Engraving Hi Vis Iron On Tape

- Reflectivity: >300CPL

- Color: Grey

- Backing Fabric: PES

- Hot Pressing Temperature: 125-135℃

- Hot Pressing Time: 8-15s

- Hot Pressing Pressure: 2-3kg/cm²

- Characteristics: Has good air permeability.

- Application: Used for lettering and hot pressing on woven, cotton, and other textiles.

Colorful Hi Vis Iron On Tape

- Reflectivity: >15CPL

- Color: Any color

- Backing Fabric: PES

- Hot Pressing Temperature: 130-150℃

- Hot Pressing Time: 10-15s

- Hot Pressing Pressure: 3-5kg/cm²

- Application: Suitable for hot pressing on woven, cotton, and other fabrics.

Rainbow Hi Vis Iron On Tape

- Color: Rainbow color

- Backing Fabric: PES

- Hot Pressing Temperature: 140-150℃

- Hot Pressing Time: 15-20s

- Hot Pressing Pressure: 3-5kg/cm²

- Application: Best used for hot pressing onto woven, cotton, and other fabrics and materials.

Hi Vis Iron On Tape: The Complete Buying Guide

Table of Contents

Why do you need hi vis iron on tape?

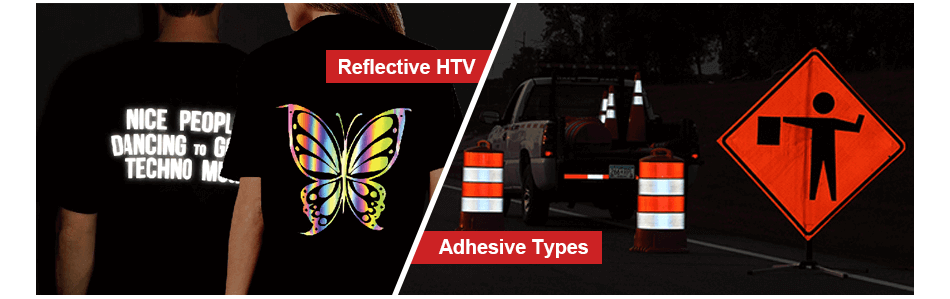

There are plenty of useful ways in which a hi vis iron on tape is used. It plays a vital role in various industries and is made out of supreme, high-grade reflective material.These materials include reflective threads, reflective sheetings, reflective fabrics, PVC reflective fabrics, reflective woven/oxford tape, reflective pattern fabric, and more. These products contribute significantly in areas pertaining to outdoor safety, road traffic safety, and more.

Some of the most widely used reflective products are as follows:

- Reflective clothing

- Reflective logos

- Reflective caps

- Reflective accessories

- Reflective gloves

- Reflective caps

- Reflective jackets

- Reflective vests

- Reflective school uniforms and more.

Before you purchase yourself a hi vis iron on tape or iron on hi visibility tape, here are a few benefits that you must keep in mind:

- Engraving designs on iron on hi visibility tape are effortless and can be done through a cutting plotter or laser machine.

- When patterns and stripes are hot-pressed onto the fabric, they turn out to be smoother, malleable, and aesthetically more pleasing.

- Iron on hi visibility tape is one of the sturdiest, compliant non-destructive materials and has a long shelf life.

- Iron on hi visibility tape is a dynamic and powerful choice, as a result of which they are preferred by top brands like Adidas and Nike for embellishing their sportswear and shoes.

What are the quality standards for hi vis iron on tape?

Here are some quality standards that are met by the hi vis iron on tape that YGM manufactures:

- They usually come in silver, gray, and other traditional colors like yellow, red, green, etc. Each color represents the level of reflectivity of that specific iron on hi visibility tape. The surface of each product is seamless, sans any black and white spots and bubbles.

- The darker the iron on hi visibility tape color is, the, the lower the reflectivity level of the product. Inverse reflection coefficient measuring instruments are used to detect the reflection level of the vinyl accurately.

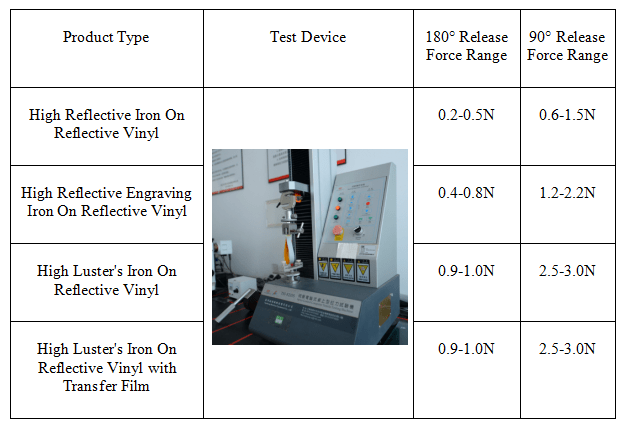

- Different materials have distinct release or adhesive forces.These forces determine the adhesion between the reflective and surface protective layer. This force is determined using a tensile testing machine.

- The direction of washing is based on the nature of the iron on hi visibility tape. ISO15797 industrial washing is the preferred mode of washing, followed by European standard ISO6330, dry cleaning, hand washing, machine washing, and more.

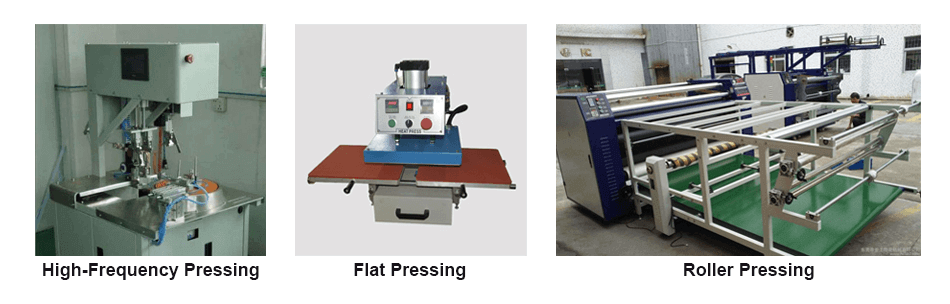

- The different pressing methods available concerning the iron on hi visibility tape are flat pressing, roller pressing, and high-frequency pressing. These are modified following various factors like the material of the product, operating environment, and more. <200°C is considered a safe and optimal operating temperature along with a pressure of <5kg/cm².

What are common applications for hi vis iron on tape?

A good iron on hi visibility tape can be put to multiple uses. Its unique features and characteristics make it one of a kind. Here are some of the most common applications of a iron on hi visibility tape:

- It is recommended for hot pressing on polyester, webbing, T/C, and other safety clothes, fabrics, textiles, and materials.

- It can be easily cut into strips and used for making logos for different brands’ merchandise.

- Iron on hi visibility tape with high luster is ideal for shoes and bags. The material is wear-resistant and scratch-resistant.

- It can be used for hot pressing on PU and PVC fabric. High Lusters PU Hi Vis Iron On Tape should only be lightly scrubbed and not for prolonged hours in water.

- High Luster’s Lettering Hi Vis Iron On Tape is used for engraving patterns and lettering. They are also used for hot pressing on polyester, webbing, and general elastic fabrics.

- High Luster’s Flame Retardant Hi Vis Iron On Tape is used for hot pressing on flame retardant fabrics, with average washing performance and high washing requirements.

Can you apply wet iron on hi visibility tape?

Iron on hi visibility tape comes with a metallic aluminum layer that prevents airing capacity, and as a result, they should never be applied wet. If the hi vis iron on tape is applied wet, the moisture will not escape from the surface. However, there are several cases when minimum wet solutions need to be used.

The iron on hi visibility tape is mostly applied wet on dark surfaces that are kept under hot and humid conditions. When it is difficult to bring down the surface to a relatively cooler temperature, a wet solution must be applied to the iron on hi visibility tape.

There are certain essential points to keep in mind if you are going to apply wet hi vis iron on tape:

- Try your best to remove as much moisture as possible when using a squeegee.

- Using a damp solution will overthrow the pH balance of the iron on hi visibility tape, and therefore the warranty of the product will cease to exist.

- The liquid may react with the aluminum layer and may lead to the breakdown of the material, or worst, result in corrosion.

- The adhesive quality of the iron on hi visibility tape is also put at risk.

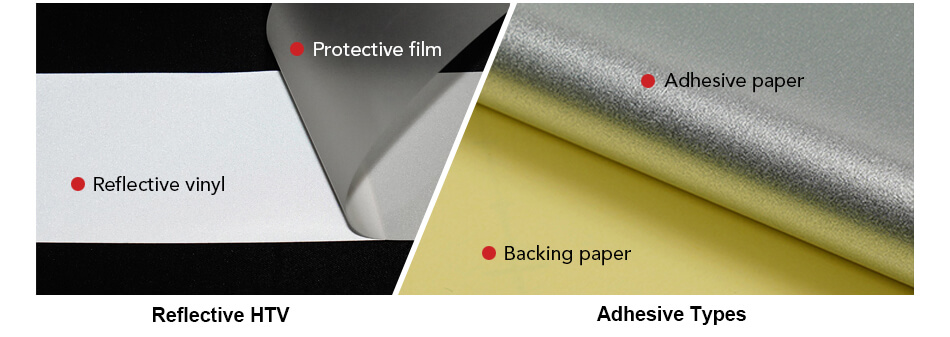

What is the difference between Adhesive Tape and Hi Vis Iron On Tape?

The difference between Adhesive Tape and Iron On Hi Visibility Tape are as follows:

1. TYPE OF BACKING: Although adhesive tape comes in diverse colors and sizes, they always have the same paper backing. When this backing is peeled off, the surface becomes sticky to the touch. Iron on hi visibility tape does not have a paper backing. It comes with a transparent plastic carrier sheet covering the top of the vinyl and does not make the surface sticky.

2. USAGE: The adhesive tape can be used directly. The hi vis iron on tape needs to be hot-pressed to attach itself to the other fabric, material, or textile.

How do you use hi vis iron on tape?

Hi vis iron on tape is used in several industries. Let us have a look at some of the most critical ways to use it:

- Iron on hi visibility tape is popularly used in beauty and fashion industries, where designs are ironed on the vinyl. Designs and patterns can be further hot pressed on the clothes, shoes, bags, and other brands’ merchandise to make them unique, quirky, and special.

How to use it?- Cut the iron on hi visibility tape into your preferred logo size or pattern of choice.

- Remove the excess material from the iron on hi visibility tape.

- Iron on the carved piece of reflective vinyl design.

- Cover the entire carved piece, put on the cotton iron mode, and press it for about 20 seconds.

- Let the carrier sheet cool for a few seconds.

- Remove the sheet, and you are ready to use your product!

- Considering that a hi vis iron on tape has been certified for following all the safety procedures and quality standards, it is chiefly used in industries that involve police officers, firefighters, and similar personnel who require it on their uniforms. A hi vis iron on tape embellishment on the uniform helps distinguish this personnel in dark and dim light.

How to use it?- To be used in safety uniforms, they are cut into strips with the required width.

- After cutting the strips into the needed size, the strips are ironed on hot-pressed using a certain temperature, pressure, and time.

- Once the solution is cooled, the protective film is taken off.

What is hi vis iron on tape?

A particular variety of vinyl polymer, a hi vis iron on tape, is used on fabrics, textiles, and other materials to establish patterns or manufacture advertising objects and products. It comes with an adhesive backrest, trimmed, weeded, and applied to the substrate for the proper heat application. Iron on hi visibility tape mostly comes in a roll or sheet package.

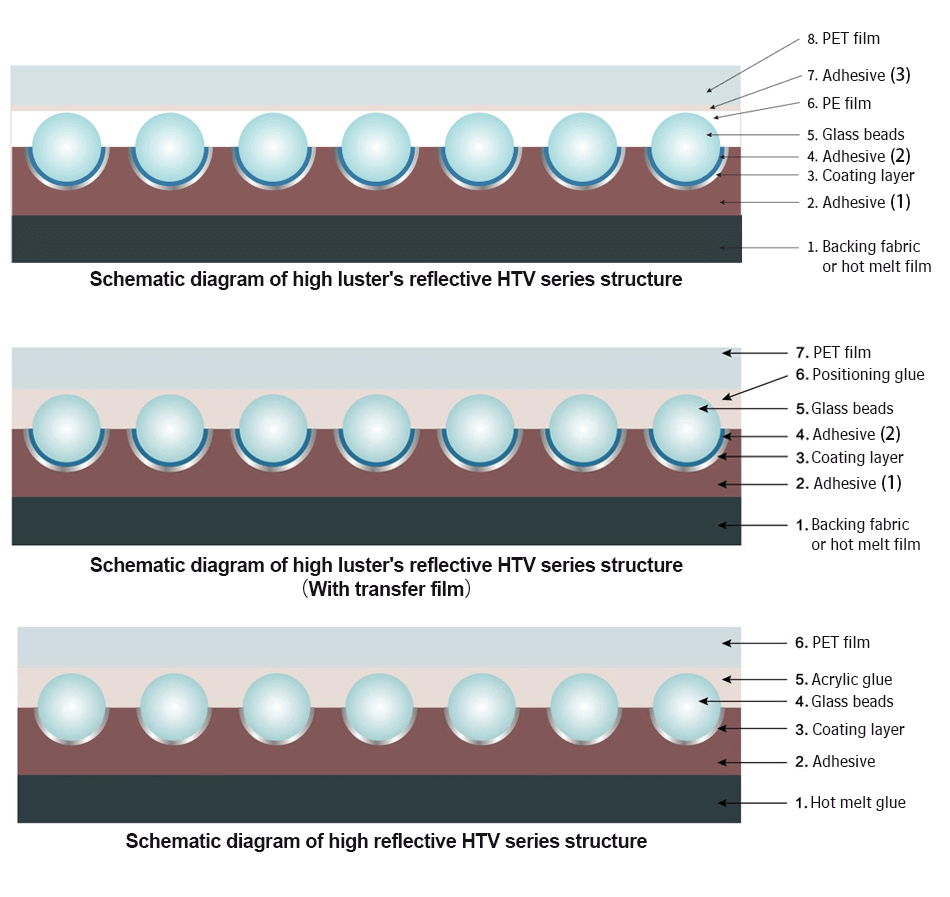

The components of a high luster’s hi vis iron on tape series structure are as follows:

- Backing fabric/ hot metal film.

- Three layers of Adhesive

- Coating layer

- Glass beads

- PE film

Iron on hi visibility tape is available in various color options, in both standard colors as well as unique color choices like the rainbow colors. Each color signifies the reflectivity rate of the vinyl.

What should I know before ordering hi vis iron on tape?

Before ordering the hi vis iron on tape, one must be thoroughly aware of the application for which they would be using the iron on hi visibility tape. They are either available to be cut and used in stripes or the form of logos for different merchandise.

If the iron on hi visibility tape has to be used to cut them into stripes, select an appropriate one that can be easily hot-pressed on the fabric it has to be used for.

Hi vis iron on tape is cut into logos through two mediums through a laser machine and a plotter.

If one requires to cut their logos through a laser machine, they must opt for PES and TPU iron on hi visibility tape. For cutting through a plotter, go for a hi vis iron on tape which has a PES backing. TPU backings can be sticky and easily trapped on the blade during the heating procedure.

The other factors to consider before ordering the suitable iron on hi visibility tape are:

- Reflective efficiency.

- Washing performance.

- Flame resistance.

There are plenty of options available, each catering to your needs and demands. One must be completely informed of the purpose they require the iron on hi visibility tape for, check the characteristics of each option, match it with their requirements, and then proceed with the purchase. You can also reach out to the team at YGM with your conditions, and they will be happy to help you make your purchase with them a success!

How do you cut hi vis iron on tape?

By now, you must be aware of the two main uses a hi vis iron on tape is bought for— for cutting them into stripes, for carving logos out of them. If you have purchased the iron on hi visibility tape to cut them into strips, you can use both — a laser machine and a plotter to achieve your desired results. Usually, an iron on hi visibility tape with a PES or TPU backing is used for this purpose. It makes the operation smoother, more convenient, and hassle-free.

For carving logos, more professional equipment is required. A cricut or a silhouette cameo 3 are some of the best options you can safely place your bets on. Install the cutting app on your computer or device. Open the design you wish you to achieve. Scale the design as per your required dimensions. And lastly, mirror the design. Mimic the pattern on the backside of the iron on hi visibility tape. Turn the vinyl back, and add the design to your shirt. And voila! You will be ready with your product!

What is the use of the transfer film in the hi vis iron on tape?

A transfer film in the hi vis iron on tape has multiple uses and is considered an incredibly efficient vinyl component. Here are some ways in which it is utilized:

- It prevents the movement of the logo.

- Since the transfer film is sticky and transparent, it makes the procedure of hot pressing the iron on hi visibility tape seamless and more convenient.

- A transfer film is usually made out of PET+ PE. It is an incredibly protective layer that helps in mitigating the risk of cloth biting.

- The PE can be easily melted at a high temperature and conveniently sticks to the fabric it is used on.

- The transfer film does not readily melt at high temperatures, making the handling of the iron on hi visibility tape easier.

How can I ensure the quality of hi vis iron on tape?

To ensure the quality of a hi vis iron on tape, here are a few steps to check and keep in mind:

- There should be a proper separation between the protective film and the gray vinyl.

- When the protective film is taken off, the glass beads must not fall off the hi vis iron on tape

- The iron on hi visibility tape should be easily cut into strips and logos for usage.

- The hi vis iron on tape should pass the washing test as per the ISO6330 standard. It should be either hand-washed or machine-washed to check its fastness and speed.

How can I make my hi vis iron on tape stick better?

At times, making the iron on hi visibility tape stick better can be an issue. To ensure that you go through a streamlined sticking process, here are a few tips to keep in mind:

- Before making the hi vis iron on tape stick, figure out the textile or fabric material you will be using. Make sure you are using the right iron on hi visibility tape with the appropriate hot pressing temperature and the desired pressure and time.

- Follow the procedure of hot pressing the hi vis iron on tape to the cloth under the right conditions. Once the process is completed and the product is cooled down, swiftly remove the protective layer.

- To assure yourself a smooth vinyl, put the heat down to a minimum temperature and press it firmly for 10 to 15 seconds.

Why is my hi vis iron on tape not sticking?

No matter how careful you are with sticking your hi vis iron on tape, there may be times when you will not be successful with the sticking process. In those situations, there are a few pointers that must be kept in mind and followed vigilantly:

- Time, temperature, and pressure are important determinants that can directly affect the sticking competency of an iron on hi visibility tape. Make sure all the settings are correct, and you follow the right directions, as per the hi vis iron on tape that you use.

- You have to be incredibly watchful of the time you press your iron on hi visibility tape for. If you press it for too long, the adhesive may burn off. If you press it for too short a time, the vinyl will not get stuck to the product and will most likely come off very easily.

- Every vinyl has a different recommended temperature for usage. Make sure you check for yours and ensure that the temperature criterion is fulfilled.

- You should apply enough pressure that the weave of the cloth should be visible through the hi vis iron on tape. You can always add external factors to your household iron to exert more pressure.

- Check the quality and the material of the cloth you are pressing the hi vis iron on tape

- Use a PES-type iron on hi visibility tape to cut a logo. Use TPU type iron on hi visibility tapefor spandex fabric.

- Make sure to keep buttons, zips, thick seams, and collars out of the way of the process of sticking as it may act as a deterrent.

- Peel off the plastic carrier sheet at the appropriate time. Some require you to peel it directly after use, while some require you to peel it off once it is completely cooled. Make sure to read all the instructions thoroughly and properly before proceeding with the process.

How well does hi vis iron on tape hold up?

The efficiency of a hi vis iron on tape differs from tape to tape. Some hold better than others. An iron on hi visibility tape has one of the best standing capacities and can hold better than the garment it is stuck on. To ensure a long-shelf-life of the iron on hi visibility tape:

- Make sure you turn your clothes inside out and wash them under cold water.

- Avoid scrubbing the garment too hard.

- For best results, clean them lightly with a hand or under a delicate machine setting.

Factors like how well the hi vis iron on tape has been stuck on, the pressure exerted to adhere it to the garment, the temperature settings under which it was stuck, the quality of the fabric it is stuck on, and many more, are also directly related to how well and how long a hi vis iron on tape will hold up.

What is the suitable material to use hi vis iron on tape on?

Hi vis iron on tape is recommended to be hot-pressed on flat surfaces at a temperature of about 120-140°C. This is to ensure that the melting point of the material is more than 140°C.

The backing material of iron on hi visibility tape is also vital to consider while choosing the suitable material that the iron on hi visibility tape should be stuck on. Usually, a hi vis iron on tape comes with two different types of backing material— PES and TPU. TPU is highly elastic and is applied to elastic fabrics like PU and PVC. PES material is used for hot pressing on fabrics like cotton, polyester, nylon, webbing, and more.

Here are a few key differences between these two materials:

- PES is composed of polyester. TPU is composed of thermoplastic polyurethane.

- PES has a white translucent appearance. TPU has a transparent, translucent, matte appearance.

- PES has general elasticity. TPU has stronger, much better elasticity.

- TPU is relatively softer and more comfortable in comparison to PES.

- The washing performance of PES is better in comparison to the washing performance of TPU.

- PES can be dry cleaned better than TPU.

- PES has excellent high-temperature resistance, while TPU has good low-temperature resistance.

- The hot pressing temperature required for PES is 140-150℃. The hot pressing temperature required for TPU is 130-140℃.

What is the difference between hi vis iron on tape and reflective tape for sewing?

Here are the main differences between a hi vis iron on tape and reflective tape for sewing:

- Both the hi vis iron on tape and reflective tape comes with a carrier sheet. This carrier sheet is mostly in the form of a PET film, PE/PET composite film, or transparent safety film. The hi vis iron on tape’s carrier sheet is removed after hot pressing. The reflective tape’s carrier sheet is removed during the process of manufacturing.

- The substrate of the hi vis iron on tape is made out of either TPU and PES, both being hot melt adhesive films. The substrate of the reflective tape is made out of 100% polyester, T/C, 100% cotton, 100% aramid, and 85% polyester+15% spandex.

- A hi vis iron on tape can be cut into strips and different logos using a laser plotter or a knife. They are also applied during the process of hot pressing on fabrics, textiles, and other garments and merchandise. On the other hand, reflective tape is used for stitching safety clothing items. They are also used for water-repellent applications, following which they can be used to create reflective umbrellas.

How do you iron on hi vis iron on tape?

It is your first time trying to iron on hi vis iron on tape? Follow the steps mentioned below for an easy, smooth, and convenient process.

- Download the designing app on your computer or device of choice.

- Start by building a template on your computer.

- Cut the iron on hi visibility tape using a knife plotter or a laser plotter. Make sure that the transparent layer of the tape’s carrier sheet is facing down.

- Remove any excess vinyl leaving behind only your design on the carrier sheet.

- Let the transparent layer of carrier sheet face upwards, and carefully set the vinyl on your cloth or fabric. Using a pressure of 2-3kg/cm², press the hi vis iron on tape at a temperature of about 120°C-140°C for a good 10 to 15 seconds. If a household iron is being used, make sure to add extra pressure as per the requirement of the iron on hi visibility tape.

- Once the final result is cool, wait for 30 seconds before you gradually and carefully peel off the carrier layer.

- In case any area of design is not correctly adhered to and lifts off, press that particular area again.

What problems do consumers usually face when using hi vis iron on tape and what are the reasons?

If you are a first time user of the hi vis iron on tape, here are some of the most common problems that you are most likely to face:

- The hi vis iron on tape may not hold firmly on the garment. This usually happens when the temperature, pressure, and time under which it has been set are not appropriate or per the vinyl’s requirement.

- Treatment of the fabric with oil and water resistance can also pose problems when it comes to sticking the hi vis iron on tape to the garment.

- Make sure to check the storage condition of hot melt adhesive, the temperature requirement, the humidity under which the product is used, and its shelf life for suitable application.

- The glass beads may fall off from the surface of the iron on hi visibility tape when the glue curing time is not strong enough, or it is stopped before the actual time.

- The power of the logo machine may not be appropriately set, leading to a haphazard logo formation. There may be extra vinyl stuck that can be difficult to peel off.

- The duration and intensity of glue curing the iron on hi visibility tape may not be correct.

- The transfer film may be peeled off with extra strength and pressure than required.

- The glass beads on the surface may be embedded way too deep.

What temperature should the heat press be set on for hi vis iron on tape?

The temperature for hot pressing the hi vis iron on tape differs from product to product. Some backing materials require more temperature in comparison to others. Here are a few important temperature criteria to keep in mind for different backing fabrics: TPU and PES.

For TPU:

- Hot Pressure Temperature: 130-140℃

- Hot Pressing Pressure: 2-4kgf

- Hot Pressing Time: 12-15s

For PES:

- Hot Pressure Temperature: 140-150℃

- Hot Pressing Pressure: 3-5kgf

- Hot Pressing Time: 12-15s

Other factors to keep in mind are:

- In the fabric or the material of the product, the hi vis iron on tape is adhered on.

- The washing performance and the elasticity of the product, and much more.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang