- info@cnygm.com

- +(0)86-576-88122360

Elastic Reflective Heat Transfer Vinyl

Your Trustworthy Elastic Reflective Heat Transfer Vinyl

Manufacturer Supplier

Your Reliable Elastic Reflective Heat Transfer Vinyl

Multiple Types | Customized Stripes & Logos

- YGM is a well-established manufacturer of reflective fabric since almost two decades and we offer customized reflective fabric based on your demands.

- Elastic reflective heat transfer vinyl is a special type of fabric with excellent elasticity. It can be laser-cut into different types of logos, patterns, stripes, and other graphics as you require. The backing fabric is made of PES or TPU and the material can be hot pressed to transfer perfectly onto stretchable fabrics with ease.

Elastic Reflective Heat Transfer Vinyl

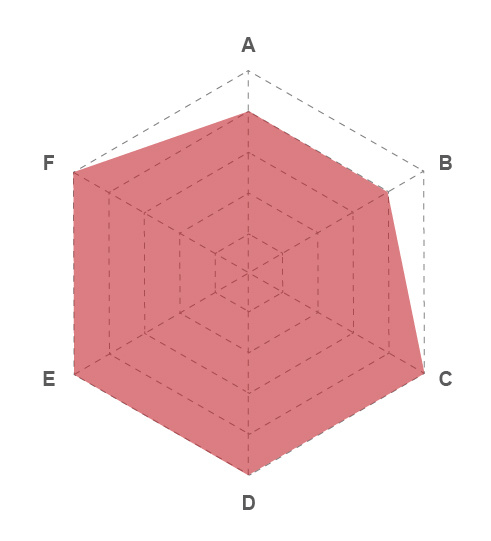

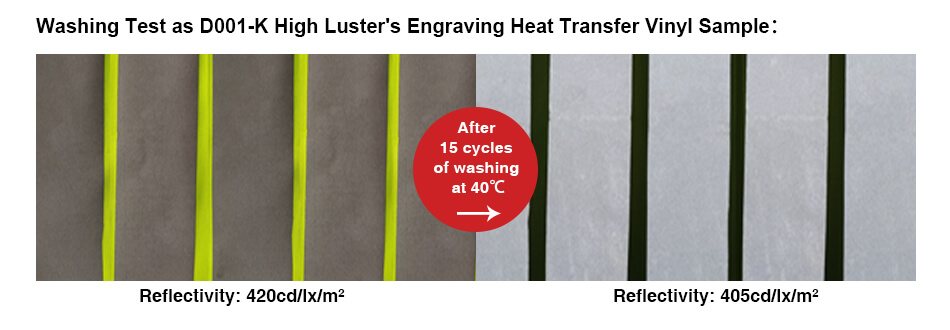

A:Reflectivity

The reflective ability of a material is determined by reflectivity units. In this case, it’s based on the product you select because it changes from one type of elastic reflective heat transfer vinyl to another. For example, silver elastic reflective HTV has a reflectivity of >420 cd/(lx/㎡) and other colors differently.

C:Washability

For elastic reflective heat transfer vinyl, there are three recommended modes of washing based on the type of product you choose. It washes well via home wash, an industrial wash, or dry cleaning according to the product.

E:Customizability

Working with an experienced manufacturer like YGM is good for creative minds because we can customize the product size and color exactly as you want. We can laser-cut into different patterns or graphics including your logos. The size and color are customizable too.

B:Color

If you’re looking for the best options to make your unique product, YGM offers multiple color options. You can pick silver, gray or any other color of your choice. Let us know and we’ll make it happen.

D:Elasticity

The stretchability of any material is called elasticity. And in this case, elasticity isn’t universal because it depends on the particular product you choose. Get in touch with us to know more about the material you’re interested in.

F:Applicability

The usability of elastic reflective heat transfer vinyl are many and expanding every day. It’s great for hot-pressing onto many different kinds of fabrics with elastics for safety or aesthetics.

Why choose YGM Elastic Reflective Heat Transfer Vinyl?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Elastic Reflective Heat Transfer Vinyl Category

High Luster's Elastic Heat Transfer Vinyl (D004)

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Wash:25cycles@40℃(ISO6330), 10cycles(ISO3175)

Hot Pressing Temperature:110-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:PES type is suitable for hot pressing on woven, cotton, etc.TPU type is suitable for hot pressing onto the fabric as PU or PVC, etc.

High Luster's Elastic Heat Transfer Vinyl (D004-7D)

Reflectivity:>200CPL

Color:Silver

Backing Fabric:PES

Wash:25cycles@40℃(ISO6330)

Hot Pressing Temperature:140-150℃

Hot Pressing Time:13-15s

Hot Pressing Pressure:3-4kg/cm²

Application:Slight elasticity, suitable for general elastic fabrics like yoga pants, PU.

High Luster's Elastic Heat Transfer Vinyl (D004-7P)

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Wash:25cycles@40℃(ISO6330)

Hot Pressing Temperature:140-150℃

Hot Pressing Time:13-15s

Hot Pressing Pressure:3-4kg/cm²

Application:Good elasticity, suitable for highly elastic fabrics like elastic band.

High Luster's Flame Retardant Elastic Heat Transfer Vinyl (D001-H)

Reflectivity:>400CPL

Color:Silver

Backing Fabric:TPU

Wash:25cycles@40℃(ISO6330), 10cycles(ISO3175)

Hot Pressing Temperature:110-135℃

Hot Pressing Time:8-15s

Hot Pressing Pressure:2-3kg/cm²

Application:Good flame retardancy and elasticity, suitable for highly elastic fabrics like elastic band.

Elastic Reflective Heat Transfer Vinyl: The Complete Buying Guide

Table of Contents

What is elastic reflective heat transfer vinyl and how does it work?

Elastic reflective heat transfer vinyl is a versatile material that can be added to any stretchable material. It’s easy for laser-cutting into patterns based on the graphics you want to add to your product.

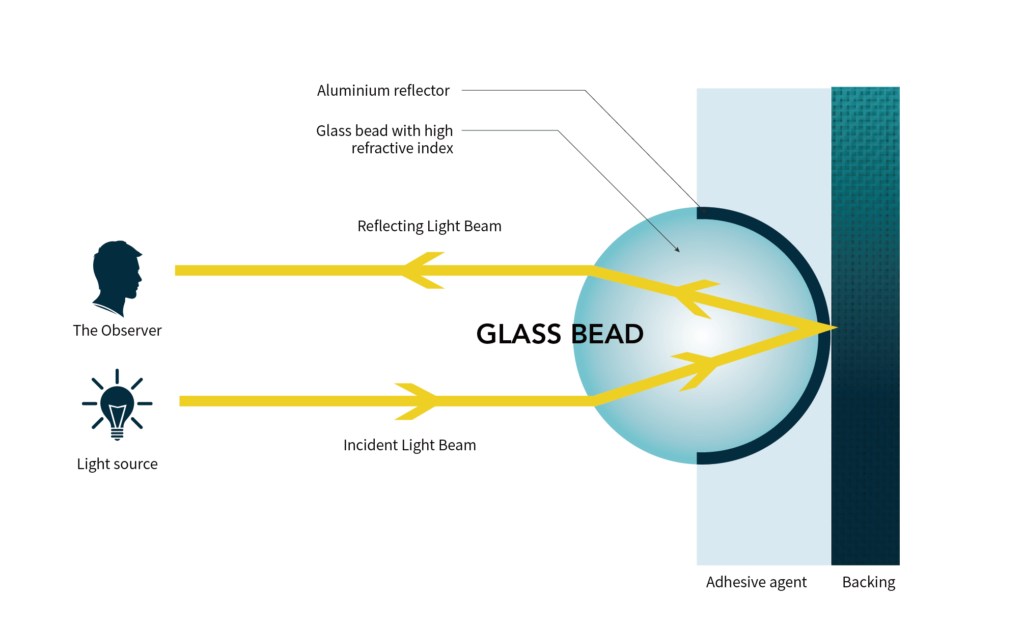

The manufacturing of elastic reflective heat transfer vinyl is based on ‘retroreflection’.

As the incident light falls on the reflective surface from its source, the reflected light goes back to the source sans any scattering effect. This happens due to several crucial materials used in making the elastic reflective heat transfer vinyl.

The most important element is the backing fabric that’s typically coated with tiny glass beads that enhance the reflective capability of light that falls on it.

What types of elastic reflective heat transfer vinyl does YGM offer?

On YGM, you can select from two options.

The first is High Luster’s Elastic Reflective Heat Transfer Vinyl models D004, D004-7D, and D004-7P.

The second is High Luster’s Flame Retardant Elastic Reflective Heat Transfer Vinyl in D001-H.

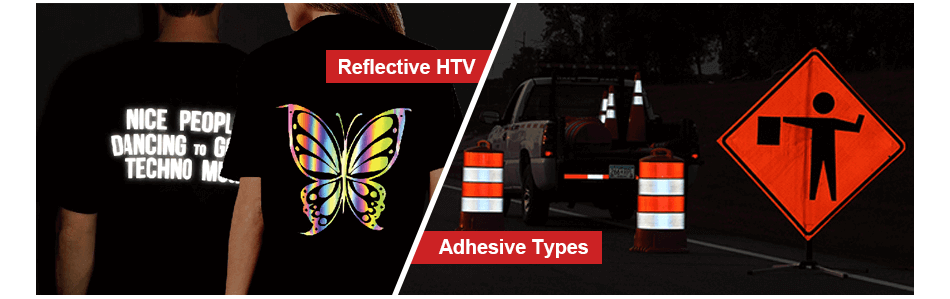

What are the uses of elastic reflective heat transfer vinyl?

Popular safety apparel all over the world uses elastic reflective heat transfer vinyl.

It’s typically cut into little strips and patterns to embed your logos using a laser machine and finally hot-pressed on your choice of elastic fabric such as those on safety wear, fashion wear, etcetera.

This fabric can also enhance the visibility of the one wearing it at night when hit by light.

Nowadays fashion of elastic fabric using reflective HTV is getting popular too. It’s a unique form of fashion that assures safety.

Does YGM Manufacture elastic reflective heat transfer vinyl?

Yes, at YGM you can get elastic reflective heat transfer vinyl based on your specifications, dimensions, and branding.

Apart from elastic reflective HTV, YGM also has a wide variety of HTV and reflective materials in-store that can enhance your inventory.

What is the size of YGM elastic reflective heat transfer vinyl?

Elastic reflective heat transfer vinyl is a fabric made for apparel applications and it’s generally available in widths of 5 centimeters, 50 centimeters, and up to 1 meter.

On top of it, you can also go for a unique size based on your needs. If you have a custom size on your mind, just relay it to our customer service and we’ll take care of it.

How long does it take for YGM to produce and deliver my order of elastic reflective heat transfer vinyl?

Once you’ve talked with a sales representative about your elastic reflective heat transfer vinyl requirement, you’ll also be informed about the shipping details and order updates specific to the order.

For products that are in stock, our delivery TAT is 25 to 35 days depending on your address and shipping preferences.

Does YGM offer free samples for elastic reflective heat transfer vinyl?

Yes, YGM offers samples for items you’re interested in, provided you pay for the freight charges. Moreover, we’ll even reimburse you the shipping charges in the invoice for your first order.

Are YGM products always available and in stock? Do I need to pre-order and await new stock for months after ordering?

While most manufacturers like YGM keep advertised products in stock, custom products take some time to be produced fresh.

Regular products that you see in our brochure on the website are always in stock but custom reflective materials are made to order.

But that being said, YGM has a small TAT for producing elastic reflective heat transfer vinyl because we’re a well-established factory with several workshops and assembly lines.

Hence, our TAT is shorter than what you’d find with reflective fabric vendors around the world.

What type of materials can you use elastic reflective heat transfer vinyl on?

Ideally, elastic reflective heat transfer vinyl is great for hot pressing on fabrics that can resist temperatures above 140 degree-coliseum because HTV works at around 120 to 140 degrees celsius.

TPU is the elastic component in elastic reflective HTV.

However, keep in mind that it’s not good for nylon and any water-repellant or water-absorbent fabrics including mesh.

What are the quality control measures used to produce elastic reflective heat transfer vinyl?

At YGM, we take quality control with utmost seriousness.

Here are steps used to reinforce it:

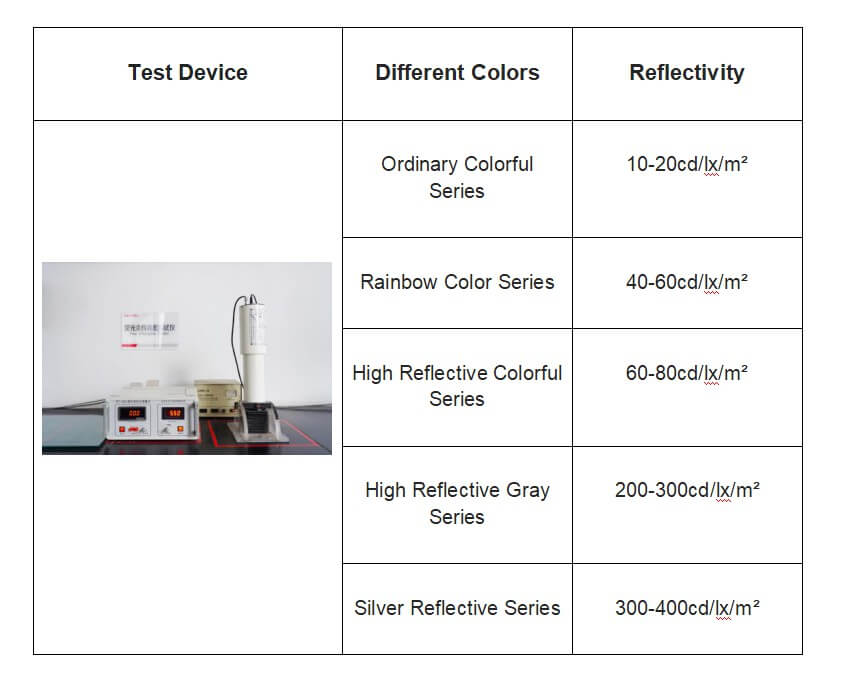

- Reflectivity: Depending on the type of elastic reflective heat transfer vinyl, the reflectivity value of the material differs. We use technical instruments such as the inverse reflection coefficient to detect the reflectivity of material accurately.

- Surface color: The elastic reflective HTV isn’t available in just one color. You can select from colors like silver, gray, etcetera. We assess the quality of the surface for blemishes, white/black spots, or even bubbles on the surface that look like anything off from seamlessness.

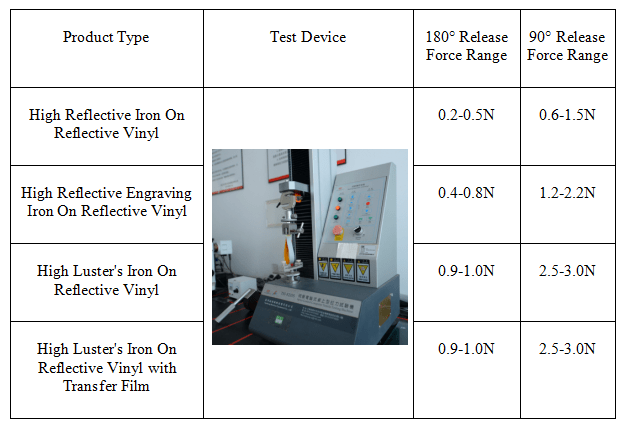

- Release force: The strength of adhesiveness between the protective layer on the surface and the reflective layer is the release force. It’s crucial for assessing the quality of hot-pressing with the force release at either a 90 or 180-degree angle. It can be analyzed using a Tensile Testing Machine. For instance, it differs for different types of elastic reflective heat transfer vinyl material such as 0.2 to 0.5N and 0.6 to 1.5 N for 180 and 90-degree angle forces respectively for High Reflective HTV, 0.9 to 1.0N, and 2.5 N to 3 N for High Luster HTV. When you go for High Luster Reflective HTV with transfer film, the 180 and 90 angle forces reach 0.9 to 1.0 N and 2.5N to 3.0N.

- Washing quality: For elastic reflective HTV, there are three modes to wash- home wash, dry cleaning, or industrial wash based on the specific type.

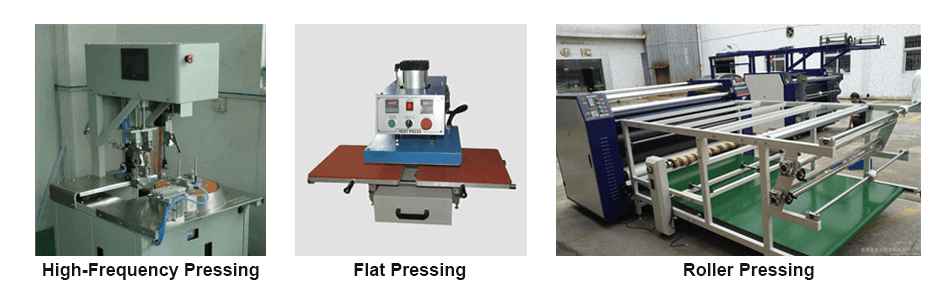

- Hot-pressing: There are different ways to press elastic reflective heat transfer vinyl from flat pressing to roller pressing, high-frequency pressing, and so on. The ideal operating temperature for this type of material is less than 200 degree-celsius with a pressure of <5kg/cm².

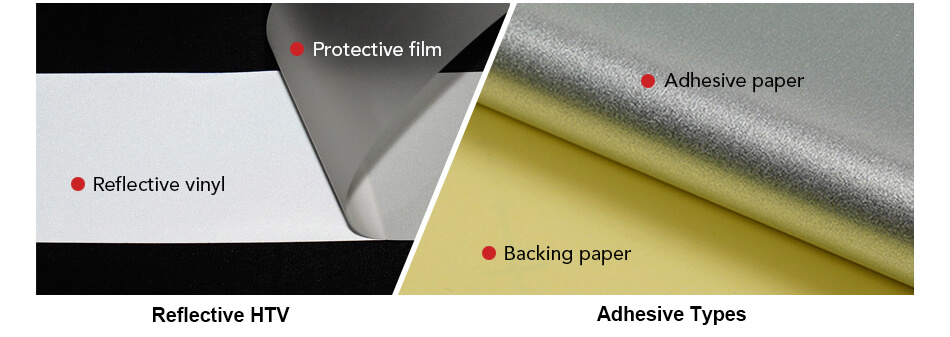

What is the difference between adhesive reflective tape and elastic reflective HTV?

Let’s look at the key differences between the two materials in detail:

- Elastic Reflective HTV

This type of material comes with great elastic features so that it’s easy to hot press it on a variety of fabrics that are stretchable and elastic.

The HTV side comes with a clear protective film covering the vinyl from above in this case.

Moreover, elastic reflective heat transfer vinyl isn’t suitable for adding to random surfaces as it works best on stretchable garments, fabrics, and similar materials.

- Adhesive reflective tape

Adhesive reflective tape isn’t an option that comes with any stretchability. The adhesive of the reflective tape comes with a paper-backing that sticks to touch, especially when the backing paper is removed.

Moreover, you can add the adhesive reflective tape material to different surfaces such as trucks, trailers, cars, cycles, boats, mailboxes, etcetera.

How can I ensure the quality of elastic reflective heat transfer vinyl?

Every type of elastic reflective HTV comes with its own specific directions for use.

Once you adhere to these directions, you can ensure the quality of the reflective material remains optimum in all cases.

Here are a few tips to help you out:

- Check if the surface of the elastic reflective heat transfer vinyl is smooth.

- Check whether you can see any blemishes such as white or black spots on the surface of the reflective material.

- Remove the protective film to assess the material and evaluate the presence of glass beads present on it.

- Engrave the logo of your brand as per needs and remove the excess elastic reflective HTV from the logo carefully.

- Check if the surface gets wrinkled once you hot press the elastic reflective heat transfer vinyl.

- You can rub the reflective surface gently with your fingers to check if the glass beads detach and drop.

How do you iron on elastic reflective heat transfer vinyl?

When you’ve ordered elastic reflective heat transfer vinyl in bulk, it’s important to learn how to iron on or hot-press it carefully. Take a look at the stepwise guide below to do it:

- Create a template for cutting out the material on your computer.

- Take a plotter or a laser machine to create cuts out of the elastic reflective heat transfer vinyl including the protective film on the carrier that faces down.

- Cut out any excess heat transfer vinyl elastic reflective material to ensure your design is exactly cut out.

- Take the HTV material on the cloth with the protective film (transparent) layer on the adhesive area facing upwards.

- Start hot pressing the material between the temperatures of 120 to 140 degree-celsius between 12 to 15 seconds.

- For home iron presses, press it under immense pressure.

- Once the surface has cooled off for at least 30 seconds, you should remove the protective film off the carrier layer by peeling softly.

- If you notice any part of the elastic reflective HTV lifting up unduly, repeat the process of hot-pressing until it’s perfect.

What should I know before ordering elastic reflective heat transfer vinyl?

Elastic reflective heat transfer vinyl isn’t like other materials. The color and other traits keep changing based on the type of elastic reflective HTV that you select. Here are the things to keep in mind when doing so:

- Reflectivity: The ability of the surface to reflect the light from the source without any scattering is the reflectivity of the material and it differs from one color of elastic reflective HTV to another.

- Color: There are a couple of colors available for this material and you can order the specific color as per the use and style you have in mind.

- Washing: You should be aware of the type of washing you can use for this fabric such as home wash or industrial wash to prevent it from getting damaged.

- Elasticity: The stretching ability of the elastic reflective heat transfer vinyl is called elasticity. For this material, elastic ability determines its use on different applications.

- Flame retardance: When an elastic reflective HTV ensures that it prevents from catching fire, it’s constructed with the trait of preventing fires.

- Cutting: Laser cutting, plotting, and so on are the options for cutting this material.

- Hot pressing: The way a elastic reflective HTV needs to be applied to ensure the reflective surface is attached to the required area safely needs to be known before you order the material.

How do you cut elastic reflective heat transfer vinyl?

Depending on the use of the elastic reflective heat transfer vinyl, cutting it is also different. You may not be able to do it on your own with precision if you need to cut complex shapes such as logos.

You can cut elastic reflective HTV with a plotter or laser cutting machine to ensure you’re cutting it out precisely based on the logos, patterns, or other requirements.

Typically, you can use the plotter to cut elastic reflective HTV made with backing fabrics such as TPU or PES.

What is the use of the transfer film in the elastic reflective HTV?

Called the protective film or the layer on a carrier film, the transfer film on any reflective material that needs to be hot-pressed with HTV ensures accurate transfer of reflective elements wherever you need it. Such a film is crucial for preventing undue movement of the logo or pattern while hot pressing.

As the film itself is sticky and transparent, it’s a plain sail to hot press the elastic reflective HTV onto different stretchable materials.

A protective film is crucial for preventing cloth biting of the reflective material. That’s because the regular transfer film is constructed with PE and PET.

While PE melts off when the temperature hits high and sticks to the fabric you want, PET-only film doesn’t melt at higher temperatures and ruin your entire endeavor.

Apart from these factors that affect the quality of hot-pressing, many customers require a protective film or transfer film for many other things. It may include assessing shapes, patterns, and designs necessary for elastic reflective HTV application.

How can I make my elastic reflective heat transfer vinyl stick better?

There are many ways to ensure your elastic reflective HTV has a better adhesion that’s exactly as advertised by the manufacturer.

Here’s what you can do to ensure the quality of such a material lasts forever:

- You need to find out a few things about the elastic reflective heat transfer vinyl material you’ve ordered first. It will help you determine the temperature required for hot pressing the material with accuracy including the pressure and time required to do the same.

- By observing favorable conditions of hot pressing, you can iron on the elastic reflective HTV to approved stretchable fabrics easily. Make sure you use an end-fabric that’s compatible enough. Once done, remove the protective film when you’re sure it’s done cooling.

- You need to make sure the heat is applied at the right pressure. To do so, you should transfer the heat little by little and press the pattern for between 12 to 15 seconds. This ensures the vinyl transfer is smooth and seamless that lasts without friction for a long while.

Why is my elastic reflective heat transfer vinyl not sticking?

The adhesiveness of the elastic reflective HTV can tamper if you don’t take care of the most important things when applying or using it.

The following will help you cite all the directions and tips you need to be wary of:

- Have you checked if all the criteria are fulfilled? Check whether the hot pressing time was sufficient, temperature for doing so was optimum, the pressure was applied at the right place for the right amount of time. All these are crucial to ensure your elastic reflective HTV adhesion is reliable.

- The type of fabric you’re hot pressing onto is as important as the application itself. That’s why you should make sure it’s compatible with the elastic reflective HTV you’re using.

- Other main problems can arise from the thickness of the seams, buttons that are huge, zips that protrude out, and collars that cause friction. Make sure its construction adheres to the requirements.

How well does elastic reflective heat transfer vinyl hold up?

When it comes to reflective fabrics, the base composition includes glass beads, aluminum foil, and so on. That’s why elastic reflective HTV will last way longer than the stretchable cloth you affix it on.

However, this is possible only when you turn clothes inside out while washing them.

Also, make sure to only wash fabrics with reflective patches on in cold water alone. Avoid any harsh scrubbing too.

What is the difference between PES and TPU backing?

There are two main backing fabrics used for creating the backing material of elastic reflective HTV. It could differ based on the reflective material you choose with elasticity.

- TPU

Derived from Thermoplastic Polyurethane, TPU has been popular since 1937. It’s a strongly elastic element used on highly stretchable fabric bands.

TPU could be transparent, translucent, or even matte with a high degree of softness and comfort. The temperature resistance is good at low degrees.

- PES

Derived from the chemical name polyethersulfone, PES is not as elastic as TPU, but it still is stretchable to a degree.

It’s a kind of polyester fabric that’s great for basic elastic fabrics like leggings, yoga pants, vests, etcetera.

PES is typically a white translucent fabric with a generic degree of softness and comfort with good temperature resistance at high degrees.

| PES | TPU |

Composition | polyester | thermoplastic polyurethane |

Transparency | white translucent | transparent, translucent, matte |

Elasticity | general | very good |

Soft and comfortable | general | very good |

Temperature resistance | good high temperature resistance | good low temperature resistance |

What is the difference between elastic reflective HTV and elastic reflective tape for sewing?

Just like ordinary HTV is unique from elastic reflective HTV, the elastic tape is different from elastic reflective HTV too.

- Elastic reflective HTV

Such a reflective material is fairly easy to recut and redesign into different shapes and patterns that can be hot-pressed for industrial applications such as making apparel and accessories (safety and fashion).

It’s made from PES or TPU and applied with the hot-pressing technique on garments with stretchable fabric. It’s easy to cut into patterns using a plotter or laser cutting machines.

- Elastic reflective tape

This is a unique reflective time that’s made from 85% polyester mixed with 15% spandex.

Elastic reflective tapes are easy to cut according to requirements.

It’s generally sewn on compatible fabrics based on needs with stitching machines and not as easily as hot-pressing.

How do I ensure the elastic reflective heat transfer vinyl remains at its best quality?

To ensure your elastic reflective HTV material remains at its best, you need to take care of the following points:

- Find out what your elastic reflective HTV is made from and the type of fabric you’re going to hot press it on.

- Note down the pressure, time, and temperature required for hot pressing the material precisely.

- Follow directions to hot press the vinyl onto the fabric and remove the transfer film once the setup is cooled.

- Apply the right pressure and time to ensure vinyl sticks well. If it doesn’t happen, repeat the process.

- Make sure you follow washing requirements such as dry cleaning, home wash, or industrial wash as advised.

- Avoid material with thick buttons, zips, seams, etcetera to avoid ruining the hot press.

What are the fabrics you can use elastic reflective HTV on?

Any type of stretchable fabric is great for using elastic reflective HTV like synthetic, cotton, polyester, rayon, spandex, knits, etcetera.

However, you must avoid hot pressing it on water-repellant areas such as nylons.

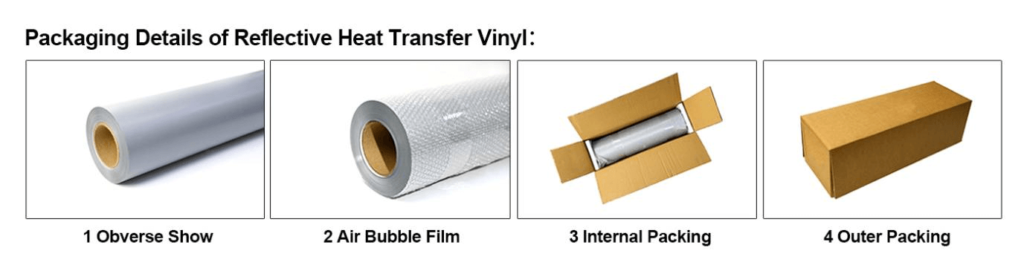

What type of packaging options do you offer at YGM for elastic reflective heat transfer vinyl?

Packing the elastic reflective HTV isn’t ordinary. Elastic reflective heat transfer vinyl box is packed with the help of high-quality materials so that it doesn’t get damaged during transport.

Generally, we make use of packaging elements that fits the roll of the elastic reflective HTV that you order.

Once the roll is safely packed, it’s again packed in corrugated boxes for hassle-free transport without damages.

That being said, if you want any different type of packaging for your order, feel free to get in touch with our customer service. It can also be modified if you have experience of items getting tampered during exit.

What is the total production capacity of YGM for elastic reflective heat transfer vinyl?

When you choose a manufacturer, it’s important to go for one that can ensure a good TAT as well as bulk order without fail.

At YGM, we are capable of ensuring orders of elastic reflective HTV of small to large sized companies can be met easily, thanks to our factory setup.

Typically, we produce about 5 million square meter of elastic reflective HTV regularly. Hence, you don’t have to finding another manufacturer when your demands increase in the future.

We have over facilities with more than 300 staff in Zheijang and a factory that stretches over 30,000 to 50,000 square meters.

Just get in touch with our customer service team to know whether we can support your bulk order regularly.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang