- info@cnygm.com

- +(0)86-576-88122360

Your Reliable Custom Safety Vests Supplier

Multiple Types | Customized Stripes & Logos

- Safety vests are mandatory safety tools in many industries. These vests help increase the visibility of the person wearing them and helps prevent injuries while working, keeping the workers safe. Considering how critical these custom safety vests are, it is vital to invest in good quality vests.

- When it comes to safety vest supplier, YGM is one trusted brand across the world. We offer our clients the best quality safety vests and also provide a lot of customization options. All you have to do is let us know your requirements, and we will manufacture the custom logo safety vests for you.

Customization Process

Why choose YGM Custom Safety Vests?

YGM VIDEO Your Trustworthy One-Stop Shop To All-Things Reflective

Custom Safety Vests Category

Custom Safety Vests: The Comprehensive Buying Guide

Table of Contents

What is a Safety Vest?

A safety vest is essential safety apparel. It is made of fluorescent fabric and reflective tape, which helps improve the reflective quotient of the vest. This, in turn, enhances the visibility of the wearer and protects their torso.

Different industries require different safety vest with company logo, which is why customization is key. Depending on the requirements of the job, safety vests can be customized to different sizes and materials. Companies who wish to add their logos or any other labels to the safety vest can get the vest customized as required too.

Why do you Need a Safety Vest?

Construction, repairs, and other high-risk industry workers are often susceptible to injuries, given the nature of the work. Unfortunately, these injuries also prove to be fatal. In such industries, it is crucial to wear the proper safety gear for protection against injuries. Custom safety vests are an essential part of this safety gear.

The whole idea of wearing a safety vest is to improve the visibility of the wearer. This improved visibility ensures that the wearer has a better chance of preventing unwanted injuries. Furthermore, custom logo safety vests are very affordable and help avoid huge expenses caused due to injuries. Also, they are comfortable, and one can work conveniently wearing them for long hours without causing any discomfort.

What Types of Custom Safety Vests Does YGM Offer?

From material resistance to safety features, YGM offers a range of personalized vests to choose from. We total have 24 types of wholesale safety vests, some of which are listed below:

Two-Tone

This safety singlet comes in a combination of two tones, such as fluorescent colors. These colors range from yellow, green, orange, black, and blue.

Vests With Pockets

The custom safety vest with pockets comes with up to 11 pockets. These pockets are internal or external, depending upon your requirement. The closures for these vests are made of zippers, Velcro, or buttons.

Pocketless

Pocketless safety vests come without any sections, pockets, or slots to store or carry accessories. These types of vests are suitable for certain types of industries and can be customized as required.

Surveyor Vest

This is a unique vest explicitly designed for those working in low visibility areas. This safety vest china is also very helpful for those working in the road or railroad sector.

Mesh Clothing

Mesh clothing safety vests are made of unique fabrics such as mesh, bird-eye, and oval mesh fabric.

Solid Vest

This safety vest is made of 100% knitted polyester or oxford fabric. These safety vests often come with the Class 2 certification and are preferred in many industries.

Breakaway Vests

Tailor-made to prevent scores of snagging-associated injuries, this vest features five breakaway points. Two of these breakaway points are located on the shoulders, two on the sides, and one on the front. These strategically placed breakaway points give complete coverage and safety to the wearer.

Adjustable Vests

These vests are preferred in many industries as they are very flexible. In addition, these vests fit varied sizes, which means employers need not get different sized vests for each worker.

Reflective Trim Vests

This safety apparel features plastic and metal rings. This mechanism helps to attach accessories easily. Wearing this safety apparel allows the wearer to attach accessories such as phones, lamps, tools with maximum safety.

EN ISO 20471 Safety Vests

These vests come in three categories – 1, 2, and 3 based on the safety standards and specifications. In these safety vests, reflective and fluorescent fabric areas are included in the design as per the regulations.

Non-Certified Vests

These are the cheapest bests as no certified body approves them. However, these wholesale safety vests, too, offer above-average standards of visibility. For non-risky jobs, these non-certified vests are perfect.

X-Back Vests

These vests have a peculiar design. They feature reflective tape on the back, which is in the shape of an X. This is typically created with a silver tape of two-inch dimensions.

Fire Resistant Vests

FR vests, as they are popularly known, are designed considering high standards of fire retardancy. Therefore, these vests are essential, especially in industries where accidents due to fire are rampant.

Insulated Vests

These vests are perfect for cold or low-temperature areas. They are water-resistant and feature an additional layer of material to ensure warmth for the wearer.

Reversible Vests

As the name suggests, these vests are reversible and wearable on both sides. This ensures 2x usability.

Public Safety Vests

This waistcoat comes in many colors, such as yellow, green, and orange.

Hi-Gloss Vests

Hi-Gloss vests come with safety clothing of Class 2 ANSI certification. These vests are designed with a high quantity of reflective material compared to any other safety vests, resulting in improved gloss, which in turn results in increased visibility.

Hi-Vis Vests

These vests are also referred to as Hi-Viz clothing. Constructed with luminescent material, this vest enhances the visibility of the wearer in low lit areas.

What Materials Available Does YGM Produce Custom Safety Vests?

Different types of vests require different types of material. Depending on the type of vest, the material is chosen, considering various aspects such as reflectivity quotient, required visibility, nature of the job, and the risk of the work. The different types of materials used by YGM to manufacture these vests are 100% polyester knitted fabric, Mesh fabric, Bird’s eye fabric, etc.

What Should I Know Before Ordering a Safety Vest? What are the Most Important Things to Keep in Mind?

Some of the important aspects you need to keep in mind before placing your order for safety vests are:

Reflectivity

The visibility of the safety vest wholesale ultimately depends on the reflectivity quotient of the material used. Safety vests should feature retro-reflective panels which function effectively during the day as well as at night. Also, 360-degree visibility is an important criterion. Even when the wearer lies flat on the ground, the vest should be able to deliver 40% visibility. Irrespective of the direction you face, the vest should be just as visible.

Durability

Some types of work require the workmen to wear the custom logo safety vests every day. In such cases, the durability of the vest is critical, as it has to be long-lasting as well as effective enough, irrespective of the nature of the work.

Washability

Only vests that are made of heavy-duty, durable material can be washed in a washer. So, it is essential to ensure that the vest is made of good quality, washable material. Irrespective of the washability of the material, it is important not to expose the safety vest to harsh detergents or bleach, as these can dull away the reflectivity of the stripes.

Comfort

Safety vests have to be worn for prolonged hours, which is why they also need to be super comfortable. While most wholesale safety vests are adjustable and feature straps to loosen or tighten the vests as required, it is also important to consider the size needed for plus-sized workers. Also, it is essential to use vests made of lightweight, sweat-repellent material such as polyester. This makes the vest comfortable to wear even in hot and humid weather.

Pockets

Pockets are super handy, especially for workers who frequently need to use tools. With pockets, it is very easy to place tools such as walkie-talkies, torches, and other essentials. Depending on the requirements, you can opt for vests that come with interior or exterior pockets.

Does OSHA Require Safety Vest?

The Occupational Safety and Health Act (OSHA) of 1970 makes reflective vests mandatory for all types of industries. It also clarified that though OSHA recommends vests only for non-flaggers, all highway and road construction workers need to wear custom safety vests.

Does YGM Manufacture Custom Safety Vests? Can I Order a Safety Vest from YGM?

Yes, YGM manufactures safety vests, and you can place your order with us. If you wish to order standard vests, you can simply select the product from our catalog and place an order with us. If you require custom logo safety vests, do let us know your specifications. Depending on your requirements, we will manufacture safety vests accordingly.

What Size Safety Vest Should You Wear?

Every organization would require different sizes of safety vests to cater to the requirements of different employees. Varied styles of custom safety vests are available at YGM. To place an order, do check out our size chart, where we have specified the different sizes as well as styles of safety vests. You can also consult our sales team for more information concerning the available sizes of safety vests.

Can I Order a Custom-size Safety Vest? Are the Accessories Customizable too?

Yes, you can place an order for a custom size of a safety vest. All you need to do is let us know your specifications and the quantity in which you require the vest, and we will manufacture the batch for you.

Not only size but fabric and color can also be customized as required. Along with this, the custom printed safety vests can also be accessorized to meet different work requirements. The accessories include the closure of different types such as zipper, hook, loop, or buttons. Additionally, you also have other alternatives such as pockets, piping, washing label, woven label, hangtag, reflective tapes like fire retardant, PVC, silver or gray tape, and even woven warning tape.

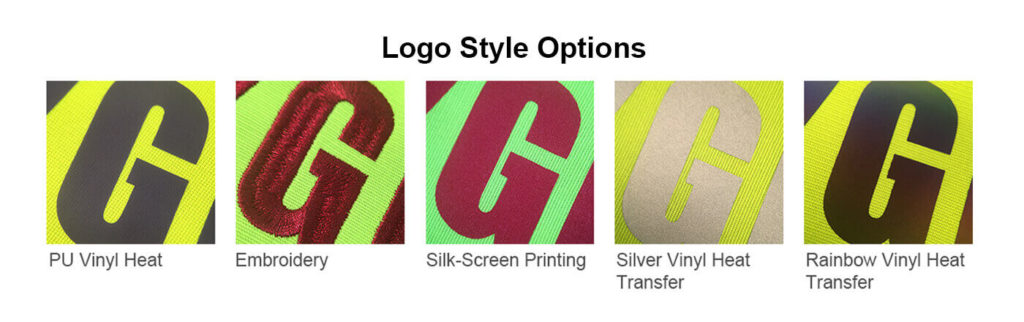

When Customizing Safety Vest, What are the Options for the Logo?

Many organizations want the custom logo safety vests to feature the logo or brand of their company on the safety vests. At YGM, we cater to such customization requirements too. We use different techniques to affix the logo on the custom printed safety vests. Screen printing and embroidery are two of them. The most commonly used procedure is vinyl heat transfer, via which we hot press silver, rainbow, or other colored vinyl HTV tape onto the custom safety vests.

Can I use Reflective Heat Transfer Vinyl on my Custom Safety Vests?

Yes, reflective heat transfer vinyl (HTV) can be hot-pressed on a safety vest. This can be done in a strip or logo style, as required.

What are the Options for the Location of the Logo on the Custom Safety Vests?

The location of the logo, too, is customizable as per the client’s requirement. The most common locations for the logo are on the left or right chest. Quite a lot of organizations also prefer the logo on the back of the safety vests, while some want it both on the front and the back.

What Styles Does the Pocket of the Custom Safety Vests Have? Where can I put it?

Custom safety vests are typically available in different designs. Some of these also come with pockets. The different styles of pockets can be customized according to the requirements of our clients. However, the standard pocket designs are – patch pockets, side seam pockets, flap pockets, zippered pockets, and hidden pockets. Each of these pockets has different functionalities and can be manufactured accordingly.

What are the Styles of Washing Labels on Custom Safety Vests? Where can it be Placed?

Washing labels on safety vests come in three different styles – ordinary, colorful, and colorful woven style. These can be placed anywhere on the vest, depending on the specifications.

Can the Tags of Custom Safety Vests be Customized?

We customize safety tags for wholesale safety vests. The only condition is that the minimum order quantity you need to place is 3000 pieces.

How Long Does it Take for YGM to Manufacture Custom Safety Vests?

The usual delivery time required for us to fulfill an order is 25-35 days. This totally depends on the quantity of the order placed, the specifications, and different customization aspects. If you have placed the order for standard safety vests, we may be in a position to cater to your requirements in a lesser number of days. Also, if you require your order urgently delivered, do let us know. We will try our best to deliver it within time.

Do you offer safety vest samples? How long does the sample delivery time take?

For standard safety vest designs, we already have samples to give out. However, if you require a customized sample, we would charge a proofing fee, and after receiving that, we would begin the process of creating the sample. The proofing time is about seven days, but we will try to send out the sample as soon as possible.

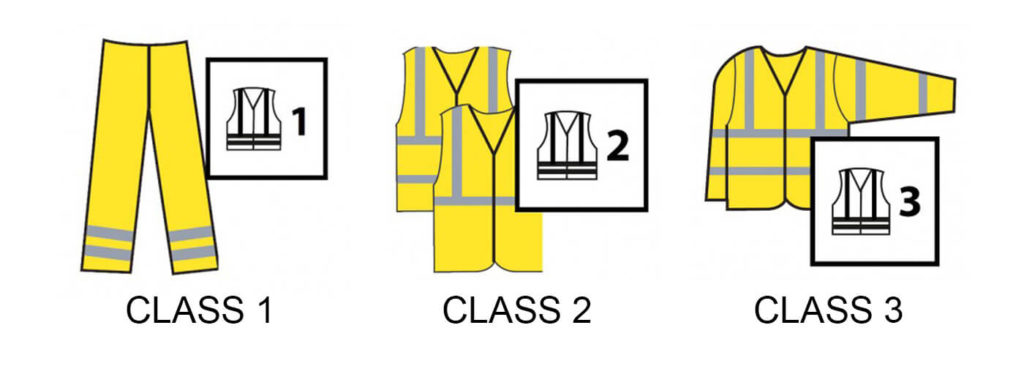

What are ANSI Class 1/2/3 safety vests?

The American National Standard for High-Visibility Safety Apparel and Accessories ANSI/ISEA 107-2015 lists the criteria for the performance of conspicuous materials. These include the minimum background requirement, retro-reflective and combined-performance materials, colors, and placement of materials. These criteria are applicable for garments, supplemental items, and accessory items used to improve the visibility and safety of workers.

Based on the visibility and expected use of these safety clothing, they are categorized into three types. These three categories are off-road (type O) roadway and temporary traffic control (Type R), and public safety activities (Type P)

ANSI/ISEA 107-2015 consolidates the requirements of ANSI/ISEA 107-2010 and ANSI/ISEA 207-2011 into a single, all-inclusive document. This document can be referred for all related occupational tasks. The 2015 edition lists three types of high visibility safety apparel based on the expected use as well as work activities. The 2015 standard also makes an allowance for procurement and manufacture of small-sized garments to fit smaller workers. It also adds specifications for additional accessories such as gloves and armbands.

Non-ANSI Safety Vests (Class 1 Safety Vests)

Non-ANSI vests do not meet the ANSI/ISEA standards. These safety vests are also known as non-ANSI safety vests and are to be used only where the traffic does not exceed 25mph. These safety vests are super economical and can be used by workmen in jobs that are not high risk. They are often worn by parking lot attendants, warehouse workers, shopping cart retrievers, and basically those who require high visibility without worrying about meeting the ANSI standards.

Class 2 Safety Vests

These vests meet the requirements stated by the ANSI 107-2015. Class 2 vests are perfect for all workers who are within the public right-of-way Federal-Aid highway. The provisions of these vests are as follows – they should have a minimum background fabric of 77 sq. inches and a minimum reflective material of 201 sq. inches. The width of the latter should be 35mm. In short, the workers who can actually wear these wholesale safety vests are school crossing guards, toll gate and parking personnel, airport crews, and personnel directing traffic.

Class 3 Safety Vests

Like the class 2 vests, these vests meet the ANSI 107-2015 standards. However, they provide higher visibility as compared to the class 2 vests. The minimum background fabric in these is 1240 sq inches, and the minimum reflective tape required is 310 square inches with a minimum width of 50 mm. The workers who can wear these vests are utility workers, survey crews, emergency service personnel, and roadway construction workers.

What is the Difference Between ANSI Class 2 and Class 3 Safety Vest?

While both Class 2 and Class 3 vests meet the requirements as mentioned by the ANSI 107-2015, the difference lies in their specifications. Class 2 vests have a minimum background fabric requirement of 77 sq inches, whereas class 3 vests require 1240 sq inches. The reflective tape requirement for the former is 201 sq inches, and the latter is 310 sq inches, respectively.

What is Type P/O/R?

Public Safety Use vests are broadly classified into three types – Type P, Type O, and Type R. Class 2 and Class 3 safety vests encompass these three types.

Type P

These vests feature enhanced visibility and are very helpful for emergency and incident responders. They are also used by law enforcement personnel or any personnel exposed to traffic on public highways or roadway temporary traffic control (TTC) zones.

Type O (Off-Road)

This category of safety vests is also known as Occupational HVSA for non-roadway use. It provides enhanced visibility to workers in both daylight and nighttime. Type O vests are well-suited for those working in traffic-facing jobs such as highways, roadways, and other such traffic zones.

Type R (Roadway)

Type R safety wear is also known as Occupational HVSA for roadway usage. This, too, is great for using day and night and is often used by workers who require enhanced visibility while on duty. Any type of work with exposure to traffic requires these safety vests as they provide improved conspicuity to the wearer.

What is Performance Class 1/2/3 Type P/O/R?

There are three performance class types when it comes to high visibility safety apparel – Performance Class 1, Performance Class 2, and Performance Class 3. We will understand each of these in brief:

Performance Class 1

The Type O safety vests mentioned above fall under this category. Performance class 1 safety apparel provides a minimum amount of high-visibility material. These are generally used in non-complex work environments, where the risk of getting injured is low but not zero. The performance class 1 vests are adept enough to differentiate the wearer from his surroundings and are perfect for low-risk jobs. Thanks to these reflective safety vest suppliers, the operative detection and identification distances in the work environment can be shorter while providing maximum safety.

Performance Class 2

This class includes both Type R and P safety apparel. The safety apparel coming under this category offers additional amounts of high visibility. The high-quality material used to design these apparel makes it more effective in terms of its visibility. Performance Class 2 HSVA delivers long detection and identification distances. As compared to the Performance Class 1 safety wear, Class 2 offers increased conspicuity performance.

Performance Class 3

Class 3, too, includes both Type R and P HSVA. This category offers excellent visibility to the wearer in complex, high-risk work environments. In this category, the specifications for the placement of background, retroreflective and combined performance materials on sleeves and pant legs are stringent. Sleeves are mandatory in the performance Class 3 category. Irrespective of the quality of materials used or regulations followed, a sleeveless garment or vest alone shall not be considered in this category.

How to Verify the Quality of Custom Safety Vests?

Just like any other safety apparel, there are many aspects that you need to look out for in custom safety vests too. This inspection helps you verify the quality of the safety vest company after you receive your sample from any manufacturing company. Let’s have a look at some of the important aspects you need to consider before finally placing the final bulk order:

Logo

The very first thing you need to look out for is the location of the logo. Thoroughly check the custom safety vests to see if the position is precise as per the specifications you gave out to the manufacturer. Likewise, also check the printing of the same on the custom printed safety vests. Was the printing of the logo done as per the method you had requested? Is the print quality good? Does the emblem come off if you pull it out? – are some things you need to check.

Size

The sizing requirements of different countries are listed out in varied formats. This is why it is essential to cross verify the sizing requirements of the custom safety vests to see if the entire order is good to go as per the EU and US standards.

Sewing and Durability

In complex work environments, the quality of the traffic safety vest manufacturers is of utmost importance. So it is advisable to check the sewing and seams of the vest to determine its durability. You surely do not want a vest to come off at critical junctures, which is why checking stitches and seams are super important.

Styling

If you have specifically requested customization in many aspects of the safety vests, ensure that you thoroughly look into all the elements. Sleeves, color, size, and overall styling are important. You need to check the sample well before you finalize the order so that the bulk order delivered is perfect in all respects.

Reflective Area

The whole idea of high visibility reflective safety vest suppliers is to deliver excellent reflective quotients. The reflective quotient is thoroughly dependent on the reflective area of the fabric used. Do check the reflective tape and dimensions of the fluorescent material to see if it meets the standards and regulations specified.

Label of the Supplier

This label is an essential part of the safety vest wholesale. While you cannot get rid of it completely, ensure that it does not clash with your brand logo or other essential design features.

How do I Ensure the Custom Safety Vests Remains at its Best Quality?

Safety wear is such that even if it is manufactured by the best company in the world with the best possible materials, it is bound to get spoiled over time. This is because of the extent of usage of these apparel and the complex work environments they are used in.

Typically, high visibility clothing lasts for six odd months based on standard usage criteria. However, in extremely tough working conditions, the custom safety vests may not make it past six months. Some signs that your vests need replacement are:

- Constantly check for wear and tear. Refer to the ANSI guidelines to know how exactly your safety vest with company logo should be and look to have a better and informed idea. If your vest does not look anything like the ANSI specifications, it is time to discard the vest.

- If the fluorescent fabric has faded and appears discolored because of excessive exposure to sunlight or any other reason, again, it is time to look for new reflective safety vest manufacturers. The damaged fluorescent material will hamper the reflectivity quotient of the safety vest, thus impacting the visibility of the wearer.

- If the reflective strips have worn out, come off, or are completely damaged, it is time to change the vest. Likewise, if the vest appears excessively dirty, ripped in places, or no longer feels comfortable enough, it needs to be replaced right away.

The duration of usage and type of work environment influence the durability of the custom safety vests. However, irrespective of these external, uncontrollable factors, it is vital to take care of the safety vests so that they remain at their best quality for as long as possible. We have listed down some ways with the help of which you can maintain the quality of your custom safety vests for a long time:

- When not in use, all high visibility clothing should be stored in an area not directly exposed to sunlight. Sunlight fades the colors quickly, hampering the reflectivity quotient of the safety vests.

- Keeping the safety vests clean is also very important. In many work environments, the vests get very dirty, making it impossible to clean them thoroughly every day. However, after a day’s work is done, wiping the vest and removing dirt stuck on it as much as possible will help prevent the accumulation of grime on the vest. This would ensure that the vest stays intact for a long time.

- Keeping the vests in a proper manner is necessary. Even though the material of the vests is easily squashable, avoiding doing so is the best way to preserve the fabric of the vest. Crumpling the vest will only put additional stress on the garment’s fibers, leading to their breakdown quickly.

- Check the label before you put the safety vest china into the washer. Every safety vest comes with a tag on which all the required essential information is mentioned clearly. Whether the vest is suitable for a machine wash or not will also be noted on the vest. The labels also say the maximum times one can wash a particular safety vest, after which the reflective strips would no longer be effective. Reading this information is crucial as it would help you schedule the washing cycles of the safety wear accordingly.

- Lastly, do keep in mind that the instructions of different brands will not be the same. If there is no label on the safety vest, contact the manufacturer for additional instructions about handling and maintenance of the safety wear.

What is the Best File Format for Logo of Custom Safety Vests to Printing?

If you wish to have the brand logo of your organization printed on the custom printed safety vests, please share the logo in good quality, high-resolution formats. The preferred formats would be CDR, AI, PDF, and EPS.

Are YGM Custom Safety Vests Always Available and In-stock? Do I Need to Pre-order and Await new Stock for Months After Ordering?

Before you place your order with YGM, please check with our Sales Team to verify the current availability of material. Mostly, we follow the produce-to-order policy, which is why you would need to place an order with us. The policy stays the same, whether it is a regular vest or a customized vest. If you have an urgent requirement, the Sales Team would be the point of contact to list out your needs. We would get back to you as soon as we can to help you with your order.

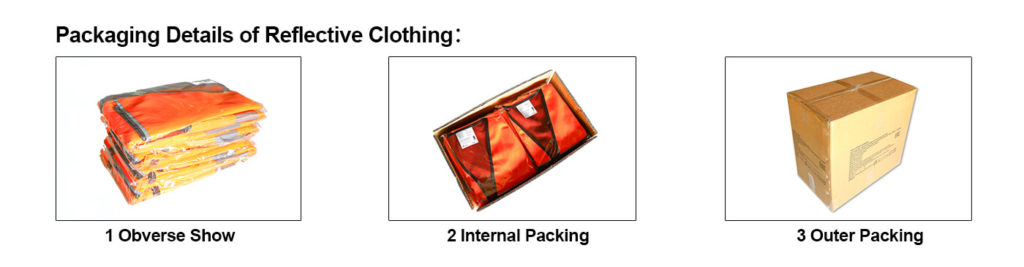

What Type of Packaging Options do you Offer at YGM for Custom Safety Vests?

Just like the quality of our vests, the packaging quality, too, is excellent. We have three layers of packaging when it comes to our safety vests. The first layer is the obverse show packing, a transparent and protective layer covering each safety vest. Next, we have the internal packing, which is done before placing the custom safety vests in the box. This packing ensures that the vests are safe during long transport durations. Lastly, the vests are placed in a carton box, which helps in easy transportation.

What is the Total Production Capacity of YGM for Custom Safety Vests?

YGM has a huge production capacity and can manufacture around two million PCS safety vests in any given month.

Summing Up

We are always happy to provide samples to our clients before they place an order with us. So if you wish to place a bulk order with YGM, drop an inquiry, and we would let you know the procedure to receive a sample from us. Once you are satisfied with the specimen you received, you can then go ahead and place the bulk order with us.

Irrespective of what your requirements are, you can always reach out to us with your specifications. At YGM, we are open to all types of customizations and are willing to manufacture all styles of vests for you. So even if you have an urgent order, do let us know, and we will try our best to deliver the same, in the best quality within the stipulated time frame.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang