- info@cnygm.com

- +(0)86-576-88122360

Basic Knowledge of Reflective Materials

Table of Contents

Introduction of Reflective Materials

What is reflective material?

Reflective material uses the principle of retroreflection (one of the types of light reflection), that is, where the light comes in and goes back out. It belongs to passive reflection that does not need to provide some additional energy, as long as there is light to do the return, to play a warning role, is a very safe, energy-saving, environmentally friendly products. Reflective material is a very difficult product, involving chemical polymers, physical optics, and high requirements for mechanical equipment, while the environmental requirements for the manufacturing process are very strict, such as temperature, humidity, the proficiency of personnel during operation, etc. Reflective materials involve a lot of raw materials, many uncertainties superimposed on each other increases the difficulty of the product.

Types of reflection of light

There are three types of reflection that you should be aware of:

- Specular Reflection

When the beam of light falls on a polished or smooth surface, then it bounces back from the surface in the same direction. This phenomenon is called specular reflection. The mirrors we look in every day are of this type.

- Diffused Reflection

When the beam of light falls on a rough surface, then it reflects in different directions, which is called diffused reflection, just like the screen of the cinema.

- Retroreflection

Retroreflection is also called return reflection, as shown in the diagram, such as driving at night, if there is reflective material, the light of the car can return to the human eye, playing a role in advance prediction. This is the reason why reflective materials were first used in some special high-risk industries.

Elements with retro-reflective properties

- Glass beads

The size of glass beads is expressed by “mesh,” which is the number of beads that can be densely arranged in a 1-inch length. The larger the mesh number, the smaller the particle size and the lower the reflectivity.

Following are the characteristics of glass beads:

- Particle Size: 30-90 microns.

- Refractive Index: Divided into high refractive index glass beads and low refractive index glass beads, reflective materials used in the high refractive index glass beads, refractive index between 1.9-2.2.Low refractive index glass beads can be used in zebra lines, the particle size of such glass beads is very large, refractive index is also low, generally between 1.7-1.9.

- Transparent: If the glass beads are not transparent, the light cannot be penetrated.

- Spherical:If it is not round and spherical, it cannot form symmetrical reflection, that is, the function of return will be reduced.

- Microprism

It is a cube composed of three perpendicular right-angled triangles, which is the same as the diamond structure, commonly known as diamond material. YGM does not currently manufacture this type of product.

Applications of Reflective Materials

- Application Area

Personal safety protection field: Reflective fabric, Reflective heat transfer vinyl, Reflective clothing, Reflective printed fabrics.

Road traffic safety protection field: Reflective tape for vehicles.

- Application Method

- Stick Directly (Pressure Sensitive Type): Our reflective sheeting workshop products are basically pressure-sensitive adhesive type, so its most obvious feature is that there must be a protective release paper behind, or also a release film (such as 3100-K).

- Sewing: It is the most used way.

- Waving: That is, weaving reflective threads and reflective yarns into clothes, hats, bags, etc.

- Hot Pressing: It’s suitable for heat transfer vinyl products and parameters such as temperature, time and pressure need to be set.

Classification of Reflective Materials

Classified by reflective elements

- Glass beads type reflective material: Can be sewn or hot pressed.

- Microprism type reflective material: Can be directly stuck or sewn, but can not be hot pressed (because the material is not resistant to high temperature, pressed will destroy the surface structure).

Classified by reflective principles

- Exposed reflective material

Glass beads are semi-exposed. Structure of exposed reflective material: bottom carrier layer, middle glue layer, and an aluminum layer (for imaging) plated under the glass beads.

Not all reflective materials have to be coated with aluminum layer, the color of the general bright reflective fabric (reflectivity is very low) without aluminum layer on the back; also can not be coated with aluminum layer, coated with other special media (light can also be reflected).

- Buried reflective material

Glass beads are not exposed outside. Structure of buried reflective material: bottom is release paper, binder layer (pressure-sensitive adhesive), aluminum reflective layer, focusing layer, glass beads, surface layer (different products surface layer is different – 3100 series surface is PET; 3200 series surface is Acrylic.)

- Honeycomb type reflective material

It’s between exposed type and buried type. With more air layer, the route of light will not change.

Brightness comparison: Exposed type reflective material > Honeycomb type reflective material > Buried type reflective material (not absolute).

- Micro-prism type reflective material

Micro-prism type reflective material is one of the types of honeycomb type reflective material.

- Summary of the Classification of Reflective Principles

- All reflective fabricsare exposed reflective materials.

- Except high intensitygrade reflective sheeting and microprism reflective sheeting, all reflective sheeting are buried reflective materials.

- Highintensity reflective sheeting is honeycomb type reflective material.

- Microprism reflective sheetingis micro-prism type reflective material.

Classified by backing material

- Sewing Type— For reflective tape for clothing

It can range from 100% polyester to T/C, polyester spandex, 100% Cotton, 100% Aramid, 100% Nylon, PVC leather, PU leather.

- Pressure Sensitive Adhesive— For reflective tape for vehicles

Can be divided into PET, Acrylic, PC, PVC, PET+ PMMA and PET+ PVC, TPU.

- Hot Press— For reflective heat transfer vinyl

There are two types: PES (no elasticity, such as D001, D001D, D001-K, etc) and TPU (good elasticity, such as D001-P, D001-H, D001-H-GS, D001-PD, etc).

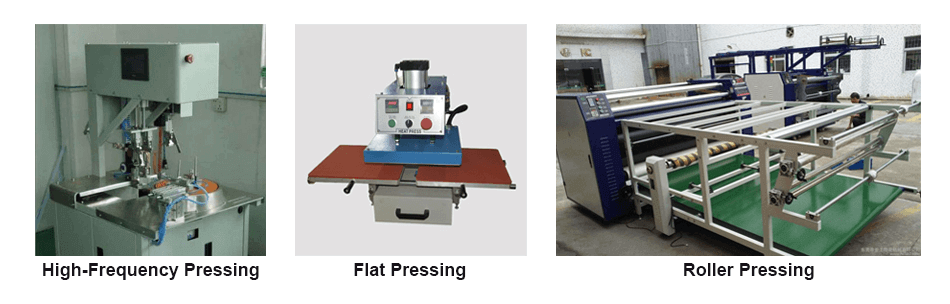

The following is the pressing method: High-frequency pressing, flat pressing, and roller pressing are the different pressing methods available.

Contact Us

- + 86-0576-88122360

- +86 18358652001

- +8615005869778

- info@cnygm.com

- 2355 Haifeng Road,Binhai Industrial Zone,Economic Development Area,Taizhou,Zhejiang